Stainless steel orifice flanges are a type of flange that is used to measure the flow of fluid through pipelines. They are used in industrial applications where precise flow control and measurement is important. The orifice flange consists of a flange with a concentric hole, or orifice, that is drilled through the center. The orifice is designed to create a pressure drop in the fluid flow, which can be measured to determine the flow rate of the fluid. The flange itself is made of stainless steel, which makes it resistant to corrosion and highly durable.

Stainless steel orifice flanges are typically used in oil and gas, chemical processing, and petrochemical industries, where they are used to measure flow rates in pipelines carrying fluids such as crude oil, natural gas, and hydrogen. They are also used in water treatment facilities to measure the flow rate of water and other fluids.

The advantages of using stainless steel orifice flanges include their resistance to corrosion and their durability. Stainless steel is also an excellent choice for food and beverage processing industries, as it is easy to clean and does not impart any taste or odor to the fluids flowing through the pipeline.

In summary, stainless steel orifice flanges are an important type of flange used for flow control and measurement in industrial applications, offering high durability, corrosion resistance, and ease of cleaning.

Table of Content:

- Orifice Flange Specifications

- Orifice Flanges Types

- Advantages of Orifice Flanges

- Application of Orifice Flange

- Orifice Flanges Materials and Grades

- Orifice Flange Dimensions

- ASME B16 36 Pressure Rating

- Orifice Flange Price List

Orifice Flange Specifications

| Orifice Flange Standards | ANSI/ASME B16.5, B16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, GOST Flange, ASME/ANSI B16.5/16.36/16.47A/16.47B, MSS S44, ISO70051, JISB2220, BS1560-3.1, API7S-15, API7S-43, API605, EN1092 |

| ASME B16.5 Orifice Flange Size Chart | 1/2″ (15 NB) to 48″ (1200NB) DN10~DN5000 |

| Orifice Flange Pressure Rating ANSI | Class 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS Orifice Flange |

| Coating | Oil Black Paint, Anti-rust Paint, Zinc Plated, Yellow Transparent, Cold and Hot Dip Galvanized Orifice Flange |

| EN | 6Bar 10Bar 16Bar 25Bar 40Bar Orifice Flange |

| Test Certificates | EN 10204/3.1B Raw Materials Certificate 100% Radiography Test Report Third Party Inspection Report, etc |

| Most common types of Orifice Flange | Forged / Threaded / Screwed / Plate |

| Connect Type/ Flange Face Type | Raised Face (RF), Ring Type Joint (RTJ), Flat Face (FF), Large Male-Female (LMF), Lap-Joint Face (LJF), Small Male-Female (SMF), Small Tongue, Large Tongue & Groove, Groove |

| Production technique | · Forged, Heat treated and machined |

| Test | Direct-reading Spectrograph, Hydrostatic testing machine, X-ray detector, UI trasonic flaw detector, Magnetic particle detector |

| Equipment | Press machine, Bending machine, Pushing Machine, electric bevelling machine, Sand-blasting machine etc |

| Orifice Flange Uses & application | · Oil Field, Offshore, Water System, Shipbuilding, Natural Gas, Electric Power, Pipe Projects etc. |

Orifice Flanges Types

There are several different types of orifice flanges available on the market today, each designed for specific applications and purposes. The most common type is a lap joint flange which consists of two pieces that fit together via bolts or screws. Another popular type is a threaded or socket-welded flange which connects pipes together with screws instead of bolts. Finally, there is also a blind flange that covers openings in pipes without actually connecting them together.

Advantages of Orifice Flanges

- The Orifice is small plates and easy to install/remove.

- Offer very little pressure drop from which 60% to 65% is recovered.

- The orifice meter can be easily maintained.

- Measures a wide range of flows.

- They have a simple construction.

- They have easily fitted between the flanges.

- They are the most suitable for most gases and liquids.

- They are cheap, The price does not increase dramatically with size.

Application of Orifice Flange

- ANSI B16.5 Class 150 Orifice Flange uses in Industrial Boilers Industry

- ASTM A182 Stainless Steel Orifice Flange uses in Power Plants Industry

- ASME B16.47 Series A and B Orifice Flange uses in Nuclear Plants Industry

- Stainless Steel Orifice Flange uses in Oil & Gas Industry

- Super Duplex Steel Orifice Flange uses in Refineries Industry

- Industrial Orifice Flange uses in Ship Building Industry

- Super Duplex Steel Orifice Flange Forged Flanges uses in Heat Exchanger Industry

- Carbon Steel Industrial Orifice Flange uses in Condensers Industry

- Alloy Steel Industrial Orifice Flange uses in Paper & Pulp Industry

- Duplex Steel Industrial Orifice Flange uses in Marine Applications

- Stainless Steel Industrial Orifice Flange uses in Nuclear Power Industry

- Industrial Orifice Flange / Fittings System uses in Fossil Fuel Power Plants Industry

Orifice Flanges Materials and Grades

| Stainless Steel Orifice Flange |

| ASTM A 182, A 240 F 304, 304L, 304H, 316, 316L, 316Ti, 310, 310S, 321, 321H, 317, 347, 347H,904L |

| Carbon Steel Orifice Flange |

| ASTM / ASME A/SA 105 ASTM / ASME A 350 , ASTM A 181 LF 2 / A516 Gr.70 A36, A694 F42, F46, F52 |

| Low Temperature Orifice Flange |

| ASTM A350 LF2, LF3, LF6 |

| Alloy Steel Orifice Flange |

| ASTM / ASME A/SA 182 & A 387 F1, F5, F9, F11, F12, F22, F91 |

| Duplex & Super Duplex Steel Orifice Flange |

| ASTM / ASME A/SA 182 F 44, F 45, F51, F 53, F 55, F 60, F 61 |

| Nickel Alloy Orifice Flange |

| UNS 10276 (HASTELLOY C 276), UNS 6625 (INCONEL 625), UNS 6601 (INCONEL 601), UNS 6600 (INCONEL 600), UNS 8825 (INCONEL 825), UNS 8020 (ALLOY 20 / 20 CB 3), UNS 4400 (MONEL 400), UNS 2201 (NICKEL 201), ASTM / ASME SB 336 UNS 2200 (NICKEL 200) |

| High Yield Orifice Flanges |

| ASTM A694 F42, F52, F60, F65, F70 |

Orifice Flange Dimensions

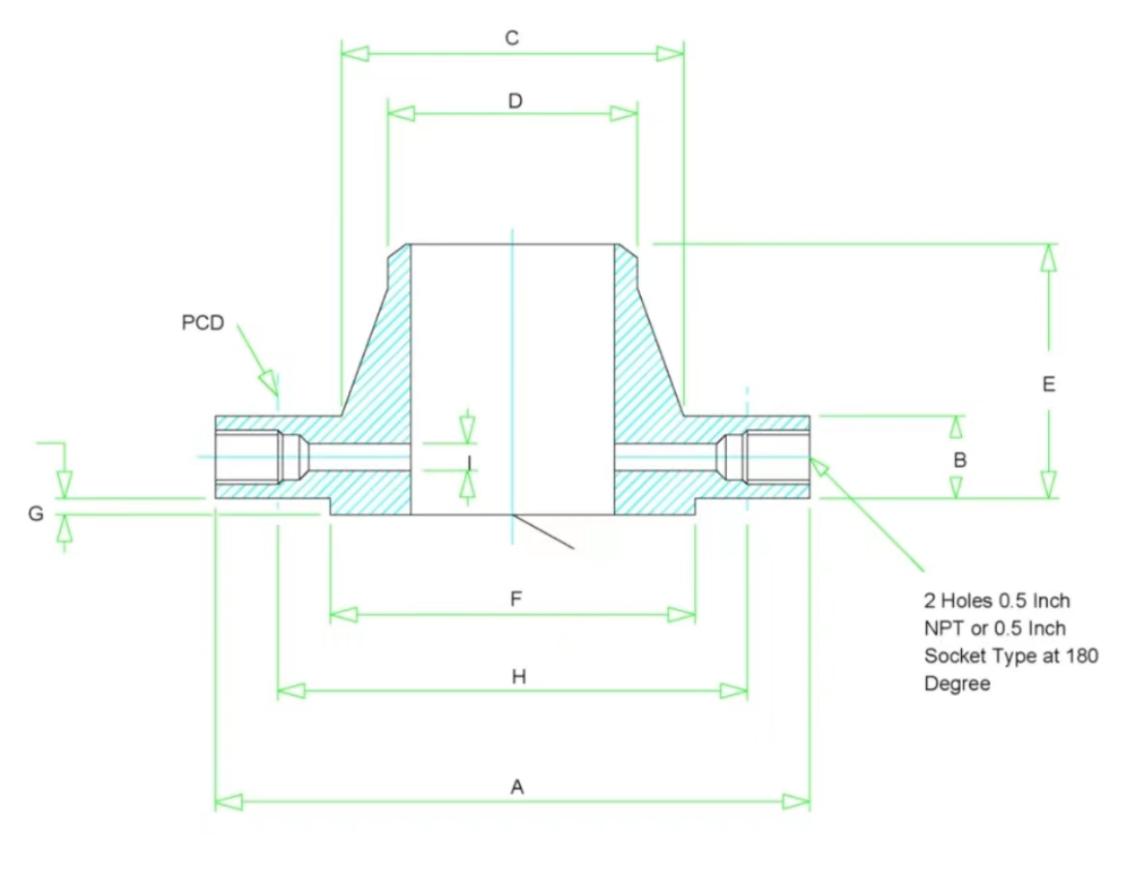

Stainless Steel Orifice Flange Dimension Drawing

Class 300 Orifice Flange Dimensions (Weld Neck Raised Face)

| Size in Inch | Size in mm | Outer Dia. | Flange Thick. | Hub OD | Weld Neck OD | Welding Neck Length | RF Dia. | RF Height | PCD | Orifice Hole dia | No of Bolts | Bolt Size UNC | RF Stud Length | Hole Size | ISO Stud Size | Weight in kg |

| A | B | C | D | E | F | G | H | I | ||||||||

| 1 | 25 | 125 | 36.6 | 54 | 33.4 | 81 | 50.8 | 2 | 88.9 | 6.4 | 4 | 5/8 | 125 | 3/4 | M16 | 4.5 |

| 1 1/2 | 40 | 155 | 36.6 | 70 | 48.3 | 84 | 73 | 2 | 114.3 | 6.4 | 4 | 3/4 | 135 | 7/8 | M20 | 6.5 |

| 2 | 50 | 165 | 36.6 | 84 | 60.3 | 84 | 92.1 | 2 | 127 | 6.4 | 8 | 5/8 | 125 | 3/4 | M16 | 7 |

| 2 1/2 | 65 | 190 | 36.6 | 100 | 73 | 87 | 104.8 | 2 | 149.2 | 6.4 | 8 | 3/4 | 135 | 7/8 | M20 | 7.5 |

| 3 | 80 | 210 | 36.6 | 117 | 88.9 | 87 | 127 | 2 | 168.3 | 9.5 | 8 | 3/4 | 135 | 7/8 | M20 | 9.4 |

| 4 | 100 | 255 | 36.6 | 146 | 114.3 | 90 | 157.2 | 2 | 200 | 12.7 | 8 | 3/4 | 135 | 7/8 | M20 | 13.2 |

| 6 | 150 | 320 | 36.6 | 206 | 168.3 | 98 | 215.9 | 2 | 269.9 | 12.7 | 12 | 3/4 | 135 | 7/8 | M20 | 14.6 |

| 8 | 200 | 380 | 39.7 | 260 | 219.1 | 110 | 269.9 | 2 | 330.2 | 12.7 | 12 | 7/8 | 145 | 1 | M24 | 30 |

| 10 | 250 | 445 | 46.1 | 321 | 273 | 116 | 323.8 | 2 | 387.3 | 12.7 | 16 | 1 | 165 | 1 1/8 | M27 | 41 |

| 12 | 300 | 520 | 49.3 | 375 | 323.8 | 129 | 381 | 2 | 450.8 | 12.7 | 16 | 1 1/8 | 180 | 1 1/4 | M30 | 62 |

| 14 | 350 | 585 | 52.4 | 425 | 355.6 | 141 | 412.8 | 2 | 514.4 | 12.7 | 20 | 1 1/8 | 185 | 1 1/4 | M30 | 84 |

| 16 | 400 | 650 | 55.6 | 483 | 406.4 | 144 | 469.9 | 2 | 571.5 | 12.7 | 20 | 1 1/4 | 195 | 1 3/8 | M33 | 111 |

| 18 | 450 | 710 | 58.8 | 533 | 457 | 157 | 533.4 | 2 | 628.6 | 12.7 | 24 | 1 1/4 | 205 | 1 3/8 | M33 | 138 |

| 20 | 500 | 775 | 62 | 587 | 508 | 160 | 584.2 | 2 | 685.8 | 12.7 | 24 | 1 1/4 | 215 | 1 3/8 | M33 | 171 |

| 24 | 600 | 915 | 68.3 | 702 | 610 | 167 | 692.2 | 2 | 812.8 | 12.7 | 24 | 1 1/2 | 240 | 1 5/8 | M39 | 247 |

Class 600 Orifice Flange

| Size in Inch | Size in mm | Outer Dia. | Flange Thick. | Hub OD | Weld Neck OD | Welding Neck Length | RF Dia. | RF Height | PCD | Orifice Hole dia | No of Bolts | Bolt Size UNC | RF Stud Length | Hole Size | ISO Stud Size | Weight in kg |

| A | B | C | D | E | F | G | H | I | ||||||||

| 1 | 25 | 125 | 36.6 | 54 | 33.5 | 81 | 50.8 | 7 | 88.9 | 6.4 | 4 | 5/8 | 125 | 3/4 | M16 | 5.5 |

| 1 1/2 | 40 | 155 | 36.6 | 70 | 48.3 | 84 | 73 | 7 | 114.3 | 6.4 | 4 | 3/4 | 135 | 7/8 | M20 | 7.8 |

| 2 | 50 | 165 | 36.6 | 84 | 60.3 | 84 | 92.1 | 7 | 127 | 6.4 | 8 | 5/8 | 125 | 3/4 | M16 | 8.3 |

| 2 1/2 | 65 | 190 | 36.6 | 100 | 73 | 87 | 104.8 | 7 | 149.2 | 6.4 | 8 | 3/4 | 135 | 7/8 | M20 | 10.8 |

| 3 | 80 | 210 | 36.6 | 117 | 88.9 | 87 | 127 | 7 | 168.3 | 9.5 | 8 | 3/4 | 135 | 7/8 | M20 | 12.6 |

| 4 | 100 | 275 | 38.1 | 152 | 114.3 | 102 | 157.2 | 7 | 215.9 | 12.7 | 8 | 7/8 | 150 | 1 | M24 | 19 |

| 6 | 150 | 355 | 47.7 | 222 | 168.3 | 117 | 215.9 | 7 | 292.1 | 12.7 | 12 | 1 | 180 | 1 1/8 | M27 | 37 |

| 8 | 200 | 420 | 55.6 | 273 | 219.1 | 133 | 269.9 | 7 | 349.2 | 12.7 | 12 | 1 1/8 | 195 | 1 1/4 | M30 | 53 |

| 10 | 250 | 510 | 63.5 | 343 | 273 | 152 | 323.8 | 7 | 431.8 | 12.7 | 16 | 1 1/4 | 220 | 1 3/8 | M33 | 86 |

| 12 | 300 | 560 | 66.7 | 400 | 323.8 | 156 | 381 | 7 | 489 | 12.7 | 20 | 1 1/4 | 230 | 1 3/8 | M33 | 102 |

| 14 | 350 | 605 | 69.9 | 432 | 355.6 | 165 | 412.8 | 7 | 527 | 12.7 | 20 | 1 3/8 | 240 | 1 1/2 | M36 | 150 |

| 16 | 400 | 685 | 76.2 | 495 | 406.4 | 178 | 469.9 | 7 | 603.2 | 12.7 | 20 | 1 1/2 | 260 | 1 5/8 | M39 | 190 |

| 18 | 450 | 745 | 82.6 | 546 | 457.2 | 184 | 533.4 | 7 | 654 | 12.7 | 20 | 1 5/8 | 280 | 1 3/4 | M42 | 240 |

| 20 | 500 | 815 | 88.9 | 610 | 508 | 190 | 584.2 | 7 | 723.9 | 12.7 | 24 | 1 5/8 | 300 | 1 3/4 | M42 | 295 |

| 24 | 600 | 940 | 101.6 | 718 | 609.6 | 203 | 692.2 | 7 | 838.2 | 12.7 | 24 | 1 7/8 | 335 | 2 | M48 | 365 |

Class 900 Orifice Flange

| Size in Inch | Size in mm | Outer Dia. | Flange Thick. | Hub OD | Weld Neck OD | Welding Neck Length | RF Dia. | RF Height | PCD | Orifice Hole dia | No of Bolts | Bolt Size UNC | RF Stud Length | Hole Size | ISO Stud Size | Weight in kg |

| A | B | C | D | E | F | G | H | I | ||||||||

| 1 | 25 | 150 | 38.1 | 52 | 33.5 | 83 | 50.8 | 7 | 101.6 | 6.4 | 4 | 7/8 | 150 | 1 | M24 | 5.4 |

| 1 1/2 | 40 | 180 | 38.1 | 70 | 48.3 | 89 | 73 | 7 | 123.8 | 6.4 | 4 | 1 | 160 | 1 1/8 | M27 | 7.8 |

| 2 | 50 | 215 | 38.1 | 105 | 60.3 | 102 | 92.1 | 7 | 165.1 | 6.4 | 8 | 7/8 | 150 | 1 | M30 | 11.5 |

| 2 1/2 | 65 | 245 | 41.3 | 124 | 73 | 105 | 104.8 | 7 | 190.5 | 6.4 | 8 | 1 | 165 | 1 1/8 | M27 | 15.8 |

| 3 | 80 | 240 | 38.1 | 127 | 88.9 | 102 | 127 | 7 | 190.5 | 9.5 | 8 | 7/8 | 150 | 1 | M24 | 22 |

| 4 | 100 | 290 | 44.5 | 159 | 114.3 | 114 | 157.2 | 7 | 235 | 12.7 | 8 | 1 1/8 | 180 | 1 1/4 | M30 | 22 |

| 6 | 150 | 380 | 55.6 | 235 | 168.3 | 140 | 215.9 | 7 | 317.5 | 12.7 | 12 | 1 1/8 | 195 | 1 1/4 | M30 | 70 |

| 8 | 200 | 470 | 63.5 | 298 | 219.1 | 162 | 269.9 | 7 | 393.7 | 12.7 | 12 | 1 3/8 | 230 | 1 1/2 | M36 | 119 |

| 10 | 250 | 545 | 69.9 | 368 | 273 | 184 | 323.8 | 7 | 469.9 | 12.7 | 16 | 1 3/8 | 240 | 1 1/2 | M36 | 204 |

| 12 | 300 | 610 | 79.4 | 419 | 323.8 | 200 | 381 | 7 | 533.4 | 12.7 | 20 | 1 3/8 | 260 | 1 1/2 | M36 | 303 |

| 14 | 350 | 640 | 85.8 | 451 | 355.6 | 213 | 412.8 | 7 | 558.8 | 12.7 | 20 | 1 1/2 | 280 | 1 5/8 | M39 | 400 |

| 16 | 400 | 705 | 88.9 | 508 | 406.4 | 216 | 469.9 | 7 | 616 | 12.7 | 20 | 1 5/8 | 290 | 1 3/4 | M42 | 510 |

| 18 | 450 | 785 | 101.9 | 565 | 457.2 | 229 | 533.4 | 7 | 685.8 | 12.7 | 20 | 1 7/8 | 330 | 2 | M48 | 738 |

| 20 | 500 | 855 | 108 | 622 | 508 | 248 | 584.2 | 7 | 749.3 | 12.7 | 20 | 2 | 355 | 2 1/8 | M52 | 932 |

| 24 | 600 | 1040 | 139.7 | 749 | 609.6 | 292 | 692.2 | 7 | 901.7 | 12.7 | 20 | 2 1/2 | 445 | 2 5/8 | M64 | 1511 |

Class 1500 Orifice Flange

| Size in Inch | Size in mm | Outer Dia. | Flange Thick. | Hub OD | Weld Neck OD | Welding Neck Length | RF Dia. | RF Height | PCD | Orifice Hole dia | No of Bolts | Bolt Size UNC | RF Stud Length | Hole Size | ISO Stud Size | Weight in kg |

| A | B | C | D | E | F | G | H | I | ||||||||

| 1 | 25 | 150 | 38.1 | 52 | 33.5 | 83 | 50.8 | 7 | 101.6 | 6.4 | 4 | 7/8 | 150 | 1 | M24 | 5.4 |

| 1 1/2 | 40 | 180 | 38.1 | 70 | 48.3 | 89 | 73 | 7 | 123.8 | 6.4 | 4 | 1 | 160 | 1 1/8 | M27 | 7.8 |

| 2 | 50 | 215 | 38.1 | 105 | 60.3 | 102 | 92.1 | 7 | 165.1 | 6.4 | 8 | 7/8 | 150 | 1 | M24 | 11.5 |

| 2 1/2 | 65 | 245 | 41.3 | 124 | 73 | 105 | 104.8 | 7 | 190.5 | 6.4 | 8 | 1 | 165 | 1 1/8 | M27 | 15.8 |

| 3 | 80 | 265 | 47.7 | 133 | 88.9 | 117 | 127 | 7 | 203.2 | 9.5 | 8 | 1 1/8 | 185 | 1 1/4 | M30 | 22 |

| 4 | 100 | 310 | 54 | 162 | 114.3 | 124 | 157.2 | 7 | 241.3 | 12.7 | 8 | 1 1/4 | 205 | 1 3/8 | M33 | 22 |

| 6 | 150 | 395 | 82.6 | 229 | 168.3 | 171 | 215.9 | 7 | 317.5 | 12.7 | 12 | 1 3/8 | 265 | 1 1/2 | M36 | 70 |

| 8 | 200 | 485 | 92.1 | 292 | 219.1 | 213 | 269.9 | 7 | 393.7 | 12.7 | 12 | 1 5/8 | 300 | 1 3/4 | M42 | 119 |

| 10 | 250 | 585 | 108 | 368 | 273 | 254 | 323.8 | 7 | 482.6 | 12.7 | 12 | 1 7/8 | 345 | 1 | M48 | 204 |

| 12 | 300 | 675 | 123.9 | 451 | 323.8 | 283 | 381 | 7 | 571.5 | 12.7 | 16 | 2 | 380 | 2 1/8 | M52 | 303 |

| 14 | 350 | 750 | 133.4 | 495 | 355.6 | 298 | 412.8 | 7 | 635 | 12.7 | 16 | 2 1/4 | 415 | 2 3/8 | M56 | 400 |

| 16 | 400 | 825 | 146.1 | 552 | 406.4 | 311 | 469.9 | 7 | 704.8 | 12.7 | 16 | 2 1/2 | 450 | 2 5/8 | M64 | 510 |

| 18 | 450 | 915 | 162 | 597 | 457.2 | 327 | 533.4 | 7 | 774.7 | 12.7 | 16 | 2 3/4 | 500 | 2 7/8 | M72 | 738 |

| 20 | 500 | 985 | 177.8 | 641 | 508 | 356 | 584.2 | 7 | 831.8 | 12.7 | 16 | 3 | 545 | 3 1/8 | M76 | 932 |

| 24 | 600 | 1170 | 203.2 | 762 | 609.6 | 406 | 692.2 | 7 | 990.6 | 12.7 | 16 | 3 1/2 | 620 | 3 5/8 | M90 | 1511 |

Class 2500 Orifice Flange

| Size in Inch | Size in mm | Outer Dia. | Flange Thick. | Hub OD | Weld Neck OD | Welding Neck Length | RF Dia. | RF Height | PCD | Orifice Hole dia | No of Bolts | Bolt Size UNC | RF Stud Length | Hole Size | ISO Stud Size | Weight in kg |

| A | B | C | D | E | F | G | H | I | ||||||||

| 1 | 25 | 160 | 38.1 | 57 | 33.5 | 92 | 50.8 | 7 | 108 | 6.4 | 4 | 7/8 | 150 | 1 | M24 | 6.5 |

| 1 1/2 | 40 | 205 | 44.5 | 79 | 48.3 | 111 | 73 | 7 | 146 | 6.4 | 4 | 1 1/8 | 180 | 1 1/4 | M30 | 13 |

| 2 | 50 | 235 | 50.8 | 95 | 60.3 | 127 | 92.1 | 7 | 171.4 | 6.4 | 8 | 1 | 185 | 1 1/8 | M27 | 19 |

| 2 1/2 | 65 | 265 | 57.2 | 114 | 73 | 143 | 104.8 | 7 | 196.8 | 6.4 | 8 | 1 1/8 | 205 | 1 1/4 | M30 | 24 |

| 3 | 80 | 305 | 66.7 | 133 | 88.9 | 168 | 127 | 7 | 228.6 | 9.5 | 8 | 1 1/4 | 230 | 1 3/8 | M33 | 43 |

| 4 | 100 | 355 | 76.2 | 165 | 114.3 | 190 | 157.2 | 7 | 273 | 12.7 | 8 | 1 1/2 | 260 | 1 5/8 | M39 | 66 |

| 6 | 150 | 485 | 108 | 235 | 168.3 | 273 | 215.9 | 7 | 368.3 | 12.7 | 8 | 2 | 350 | 2 1/8 | M52 | 172 |

| 8 | 200 | 550 | 127 | 305 | 219.1 | 318 | 269.9 | 7 | 438.2 | 12.7 | 12 | 2 | 385 | 2 1/8 | M52 | 261 |

| 10 | 250 | 675 | 165.1 | 375 | 273 | 419 | 323.8 | 7 | 539.8 | 12.7 | 12 | 2 1/2 | 490 | 2 5/8 | M64 | 485 |

| 12 | 300 | 760 | 184.2 | 441 | 323.8 | 464 | 381 | 7 | 619.1 | 12.7 | 12 | 2 3/4 | 540 | 2 7/8 | M72 | 730 |

ASME B16 36 Pressure Rating

| ASME B16.36 Pressure Pressure | |||||||

| Temperature (°C) | Class | ||||||

| Class 150 | Class 300 | Class 400 | Class 600 | Class 900 | Class 1500 | Class 2500 | |

| -29 – 38 | 19.8 | 51.7 | 68.9 | 103.4 | 155 | 259 | 431 |

| 50 | 19.5 | 51.7 | 68.9 | 103.4 | 155 | 259 | 431 |

| 100 | 17.7 | 51.5 | 68.7 | 103.0 | 155 | 258 | 429 |

| 150 | 15.8 | 50.2 | 66.8 | 100.3 | 151 | 251 | 418 |

| 200 | 13.8 | 48.6 | 64.8 | 97.2 | 146 | 243 | 405 |

| 250 | 12.1 | 46.3 | 61.7 | 92.7 | 139 | 232 | 386 |

| 300 | 10.2 | 42.9 | 57.0 | 85.7 | 129 | 214 | 357 |

| 325 | 9.3 | 41.4 | 55.0 | 82.6 | 124 | 207 | 344 |

| 350 | 8.4 | 40.0 | 53.4 | 80.0 | 120 | 200 | 334 |

| 375 | 7.4 | 37.8 | 50.4 | 75.7 | 114 | 189 | 315 |

| 400 | 6.5 | 34.7 | 46.3 | 69.4 | 104 | 174 | 290 |

| 425 | 5.5 | 28.8 | 38.4 | 57.5 | 86.3 | 144 | 240 |

| 450 | 4.6 | 23.0 | 30.7 | 46.0 | 69.0 | 115 | 192 |

| 475 | 3.7 | 17.1 | 22.8 | 34.2 | 51.3 | 85.4 | 142 |

| 500 | 2.8 | 11.6 | 15.4 | 23.2 | 34.7 | 57.9 | 96.5 |

| 538 | 1.4 | 5.9 | 7.9 | 11.8 | 17.7 | 29.5 | 49.2 |

Orifice Flange Price List

| Orifice Flange type | Orifice Flange Price in USD |

| Stainless Steel Orifice Flange | USD $ 16.92 /Kg |

| Carbon steel Orifice Flange | USD $ 15.13 /Kg |

| Alloy steel Orifice Flange | USD $10.23 /Kg |

| ANSI b16 5 Orifice Flange | USD $ 30.11 /Kg |

| ASME b16.47 Orifice Flange | USD $ 22.98 /Kg |

Wenzhou Kaixin Kaixin Metal Co.,LTD

Wenzhou Kaixin Kaixin Metal Co.,LTD