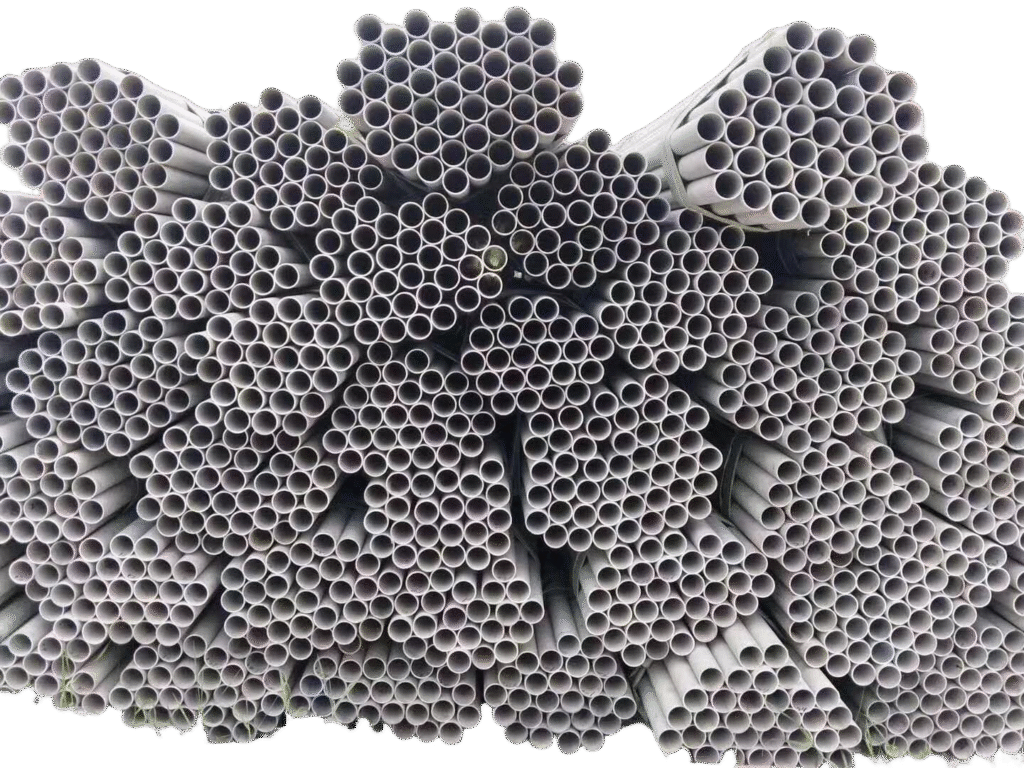

With the widespread application of stainless steel pipes, the processing quality of stainless steel pipe manufacturers is becoming increasingly important.

Stainless steel pipe manufacturers must pay attention to every aspect to ensure that product quality meets customer requirements and industry standards.

According to industry standards and customer requirements, the processing quality requirements of stainless steel pipe manufacturers can be divided into the following aspects:

1. Material quality

The material quality of stainless steel pipes directly affects the product quality.

Foshan stainless steel pipe manufacturers must strictly control the source and quality of materials, and reasonably select suitable materials and accessories.

2. Dimensional and geometric accuracy

The size and geometric accuracy of stainless steel pipes are very important.

Manufacturers must adopt professional processing equipment and technology to ensure that the diameter, wall thickness, length, and hoop strength of the pipes meet customer requirements and industry standards.

The requirement for machining accuracy should be less than or equal to 1%.

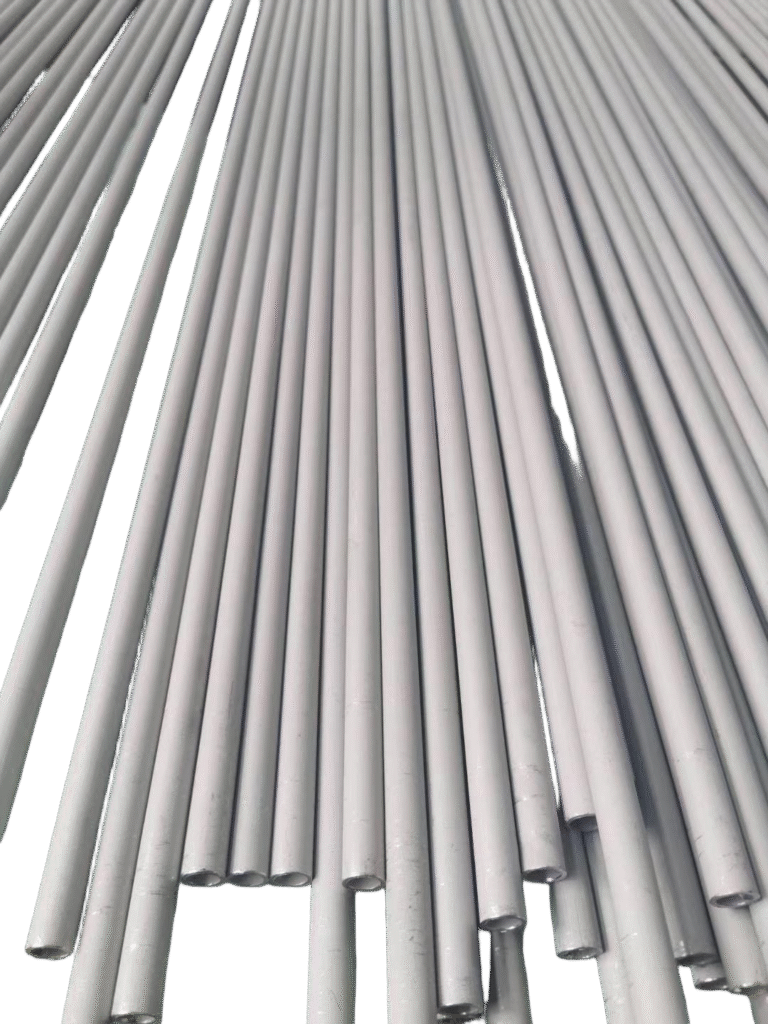

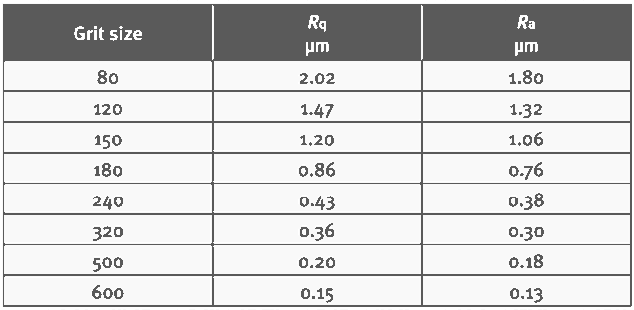

3. Surface quality

The surface quality of stainless steel pipes is the core of visual effects and corrosion resistance.

In order to achieve high-quality surface quality, Foshan stainless steel pipe manufacturers should adopt appropriate processing methods and treatment processes to eliminate surface defects such as coatings, grease, and rust.

The surface roughness should comply with national standards, and the surface finish should reach the highest quality according to customer requirements.

4. Chemical composition and properties

The chemical composition and performance of stainless steel pipes directly affect their stability in use.

Foshan stainless steel pipe manufacturers must strictly monitor and test raw materials, determine chemical composition and performance, and ensure that they meet customer requirements and industry standards.

5. Other qualities

Stainless steel pipe manufacturers must also ensure other quality of their products, such as strength, toughness, anti-corrosion performance, reliability, etc.

Corresponding testing and verification should be carried out according to customer requirements and industry standards.

In summary, stainless steel pipe manufacturers should consider material quality, dimensional and geometric accuracy, surface quality, chemical composition and performance, as well as other quality aspects when processing stainless steel pipes, to ensure that product quality meets the highest standards. Only in this way can we meet the needs of customers and shape a higher reputation and image for the entire industry.

Wenzhou Kaixin Kaixin Metal Co.,LTD

Wenzhou Kaixin Kaixin Metal Co.,LTD