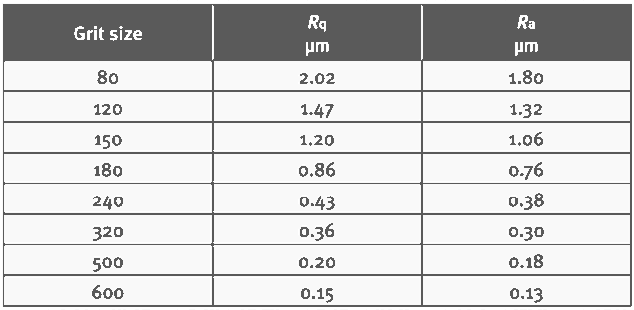

316Ti Stainless Steel Seamless Pipe is a titanium stabilised version of 316 molybdenum-bearing austenitic stainless steel. The 316 alloys are more resistant to general corrosion and pitting/crevice corrosion than the conventional chromium-nickel austenitic stainless steels such as 304. They also offer higher creep, stress-rupture and tensile strength at elevated temperature. High carbon Alloy 316 stainless steel can be susceptible to sensitisation, the formation of grain boundary chromium carbides at temperatures between approximately 900 and 1500°F (425 to 815°C) which can result in intergranular corrosion. Resistance to sensitisation is achieved in Alloy 316Ti with titanium additions to stabilise the structure against chromium carbide precipitation, which is the source of sensitisation. This stabilisation is achieved by an intermediate temperature heat treatment, during which the titanium reacts with carbon to form titanium carbides. This significantly reduces susceptibility to sensitisation in service by limiting the formation of chromium carbides. Thus, the alloy can be used for extended periods at elevated temperatures without compromising its corrosion resistance. 316Ti stainless steel world

316ti SS Seamless Pipe Specification

Stainless Steel 316ti Pipe International Specification ASTM A312/ ASME SA 312 TP 316ti Standard Specification ASME, ASTM, AISI, AMS, JIS, EN, SAE, DIN, NF, TOCT, DS, DTD, GB Stainless Steel 316ti Seamless Pipe Size OD: 4 to 219mmWall Thickness: 0.5 to 20mm 316ti SS Welded Pipe Size OD: 5.0 – 1219.2 mm SS 316ti EFW Pipe Size OD: 5.0 – 1219.2 mm ASTM A312 Grade TP 316Ti Pipe WT SCH 5, SCH10, SCH 40, SCH 80, SCH 80S, SCH 160, SCH XXS, SCH XS Stainless Steel AISI 316ti Pipe manufacturing techniques Seamless / ERW / EFW/ Welded / Fabricated / CDW/ LSAW/ Seam-Welded / Redrawn Origin of ASME SA 312 TP 316ti pipe material Indian, European, Korean, Japanese SS UNS S31703 Pipe End Types BE : Beveled endBBE : Bevel both endsBLE : Bevel large endBSE : Bevel small endTBE = Treaded Both EndsPBE = Plain Both EndsTOE / BOE = Treaded One End / Beveled One EndPOE / BOE = Plain One End / Beveled One EndTOE / POE = Treaded One End / Plain One End Form Round, Square, Rectangular ASTM A312 TP 316Ti SS Pipe Length Single Random, Double Random & Required Length End: Plain End, Beveled End, Treaded Stainless Steel Grade 316ti Pipe Delivery Condition Annealed and Pickled, Hot Finished, Polished, Bright Annealed, Cold Drawn

ASTM A312 TP316Ti Stainless Steel Pipes Equivalent Grades ANDARD WERKSTOFF NR. UNS JIS BS GOST AFNOR EN SS 316Ti 1.4571 S31635 SUS 316Ti 320S31/ 321S12 08KH17N13M2T/ 10KH17N13M2T Z6CNDT17-12/ Z6CNT17-12 X6CrNiMoTi17-12-2

Chemical Properties of ASTM A312 TP 316Ti Pipe Grade C Mn Si P S Cr Mo Ni Fe SS 316Ti 0.08 max 2.0 max 0.75 max 0.045 max 0.030 max 16.00 – 18.00 2.00 – 3.00 10.00 – 14.00 68.395 min

Mechanical Properties of ASTM A312 TP316TI Stainless Steel Seamless Pipes The Mechanical Properties of grade 316Ti Stainless Steel are displayed in the following table.

Temper Annealed Tensile Rm 75 ksi (min) Tensile Rm 515 MPa (min) R.p. 0.2% Yield 30 ksi (min) R.p. 0.2% Yield 205 MPa (min) Elongation (2” or 4D gl) 35 % (min)

ASTM A312 TP316TI Stainless Steel Seamless Pipes Physical Properties Physical properties of 316Ti grade stainless steel in the annealed condition

Specific Heat (0-100°C) 500 J.kg-1.°K-1 Thermal Conductivity 14.6 W.m -1.°K-1 Thermal Expansion 16.5 mm/m/°C Modulus Elasticity 193 GPa Electrical Resistivity 7.4 μohm/cm Density 7.99 g/cm3

ASTM A312 TP 316Ti SS Pipe Schedule and Wall Thickness Nominal O.D. Inches 10s 10 40s & Std 40 80s & E.H. 80 160 1/8 .405 .049 .049 .068 .068 .095 .095 1/4 .540 .065 .065 .088 .088 .119 .119 3/8 .675 .065 .065 .091 .091 .126 .126 1/2 .840 .083 .083 .109 .109 .147 .147 .187 3/4 1.050 .083 .083 .113 .113 .154 .154 .218 1 1.315 .109 .109 .133 .133 .179 .179 .250 1 1/4 1.660 .109 .109 .140 .140 .191 .191 .250 1 1/2 1.900 .109 .109 .145 .145 .200 .200 .281 2 2.375 .109 .109 .154 .154 .218 .218 .343 2 1/2 2.875 .120 .120 .203 .203 .276 .276 .375 3 3.500 .120 .120 .216 .216 .300 .300 .437 3 1/2 4.000 .120 .120 .226 .226 .318 .318 4 4.500 .120 .120 .237 .237 .337 .337 .531 4 1/2 5.000 .247 .355 5 5.563 .134 .134 .258 .258 .375 .375 .625 6 6.625 .134 .134 .280 .280 .432 .432 .718 7 7.625 .301 .500 8 8.625 .148 .148 .322 .322 .500 .500 .906 9 9.625 .342 .500 10 10.750 .165 .165 .365 .365 .500 .593 1.125 11 11.750 .375 .500 12 12.750 .180 .180 .375 .406 .500 .687 1.312 14 14.000 .188 .250 .375 .437 .500 .750 1.406 16 16.000 .188 .250 .375 .500 .500 .843 1.593 18 18.000 .188 .250 .375 .562 .500 .937 1.781

Stainless Steel Grade 316ti Seamless Pipe Weight Chart NPS Outside Diameter (OD) Wall Thickness (WT) Weight Weight in mm in mm Sched kg/Mtr Lb/ft 1/2″ 0.840 21 0.109 2.769 40 STD 1.268 0.851 0.147 3.734 80 STD 1.621 1.088 3/4″ 1.050 27 0.113 2.870 40 STD 1.684 1.131 0.154 3.912 80 STD 2.195 1.474 1″ 1.315 33 0.133 3.378 40 STD 2.501 1.679 0.179 4.547 80 STD 3.325 2.172 1 1/4″ 1.660 42 0.140 3.556 40 STD 3.385 2.273 0.191 4.851 80 STD 4.464 2.997 1 1/2″ 1.900 48 0.145 3.683 40 STD 4.048 2.718 0.200 5.080 80 STD 5.409 3.361 2″ 2.375 60 0.154 3.912 40 STD 5.441 3.653 0.218 5.537 80 STD 7.480 5.022 2 1/2″ 2.875 73 0.203 5.516 40 STD 8.629 5.793 0.276 7.010 80 STD 11.411 7.661 3″ 3.500 89 0.216 5.486 40 STD 11.284 7.576 0.300 7.620 80 STD 15.272 10.253 4″ 4.500 114 0.237 6.020 16.073 10.790 0.337 8.560 22.318 14.983 6″ 6.625 168 0.188 4.775 19.252 12.924 0.203 5.516 20.739 13.923 0.219 5.563 22.318 14.983 0.250 6.350 25.354 17.021 0.280 7.112 40 STD 58.263 18.974 0.312 7.925 31.334 21.036 0.375 9.525 37.285 25.031 0.432 10.973 80 XHY 42.561 28.573 0.500 12.700 48.719 32.708 8″ 8.625 219 0.188 4.775 25.233 16.940 0.203 5.156 27.198 18.259 0.219 5.563 29.286 19.661 0.250 6.350 20 33.308 22.361 0.277 7.036 30 36.786 24.696 0.322 8.179 40 42.352 28.554 0.375 9.525 49.216 33.041 0.406 10.312 60 53.085 35.638 0.500 12.700 80 XHY 64.627 43.388 10″ 10.750 273 0.188 4.775 31.588 21.207 0.219 5.563 36.689 24.631 0.250 6.350 20 41.759 28.035 0.307 7.798 30 51.002 34.240 0.344 8.738 56.946 38.231 0.365 9.271 40 STD 63.301 40.483 0.438 11.125 71.852 48.238 0.500 12.700 60 XHY 81.530 54.735 0.594 15.088 80 95.969 64.429 12″ 12.750 324 0.188 4.775 37.570 25.222 0.219 5.563 43.657 29.309 0.250 6.350 49.713 33.375 0.281 7.137 55.739 37.420 0.312 7.925 61.735 41.445 0.375 9.525 73.824 49.562 0.406 10.312 79.727 53.525 0.500 12.700 97.438 65.415 0.562 14.275 108.966 73.154 14″ 14.000 356 0.188 4.775 41.308 27.732 0.219 5.563 48.012 32.233 0.250 6.350 20 54.685 36.713 0.281 7.137 61.327 41.172 0.312 7.925 67.939 45.611 0.375 9.525 STD 81.281 54.568 0.438 11.125 40 94.498 63.441 0.500 12.700 XHY 107.381 72.090 0.625 15.875 132.983 89.278 16” 16.000 406 0.188 4.775 47.290 21.748 0.219 5.563 54.980 36.910 0.250 6.350 10 62.639 42.053 0.281 7.137 70.268 47.174 0.312 7.925 20 77.866 52.275 0.344 8.738 85.677 57.519 0.375 9.525 30STD 93.213 62.578 0.438 11.125 108.433 72.797 0.500 12.700 40XHY 123.289 82.770 18″ 18.000 457 0.219 5.563 61.948 41.588 0.250 6.350 70.593 47.393 0.281 7.137 79.208 53.176 0.312 7.925 20 87.792 58.939 0.375 9.525 STD 105.144 70.588 0.438 11.125 30 122.369 82.152 0.500 12.700 XHY 139.198 93.450 0.562 14.275 40 155.904 104.666 0.625 15.875 172.754 115.978 20″ 20.000 508 0.250 6.350 78.547 52.733 0.282 7.163 88.458 59.386 0.312 7.925 97.719 65.604 0.375 9.525 20 STD 117.075 78.598 0.438 11.125 136.305 91.508 0.500 12.700 30 XHY 155.106 104.130 0.594 15.088 40 183.378 123.110 0.625 15.875 192.640 129.328 0.688 17.475 211.368 141.901 24″ 24.000 610 0.250 6.350 94.456 63.413 0.281 7.137 106.029 71.183 0.312 7.925 117.573 18.932 0.375 9.525 20 STD 140.938 64.618 0.438 11.125 164.176 110.219 0.500 12.700 XHY 186.923 125.490 0.625 15.875 232.410 156.028 0.688 17.475 40 255.148 171.293 0.750 19.050 277.401 186.233 30″ 30.000 762 0.250 6.350 118.318 79.433 0.281 7.137 132.851 89.189 0.312 7.925 10 147.353 98.925 0.375 9.525 STD 176.731 118.648 0.438 11.125 205.983 138.286 0.500 12.700 20 XHY 234.647 157.530 0.625 15.875 30 292.066 196.078 0.688 17.475 320.817 215.380 0.750 19.050 348.988 234.293 36″ 36.000 914 0.250 6.350 142.180 95.453 0.281 7.137 159.672 107.196 0.312 7.925 10 177.133 118.918 0.375 9.525 STD 215.525 142.678 0.438 11.125 247.790 166.353 0.500 12.700 20 XHY 282.372 198.570 0.625 15.875 351.723 236.128 0.688 17.475 386.487 259.467 0.750 19.050 420.576 282.353 42″ 42.000 1067 0.312 7.925 206.914 138.911 0.375 9.525 STD 248.319 166.708 0.500 12.700 XHY 33.097 221.610 0.750 19.050 492.163 330.413 48″ 48.000 1219 0.375 9.525 STD 284.112 190.738 0.438 11.125 331.404 222.487 0.500 12.700 XHY 377.822 253.650 0.750 19.050 563.750 378.473 0.875 22.225 655.969 440.383

Pressure Rating of Stainless Steel TP316Ti Pipes316Ti Pipes Pressure Rating (psig) Pipe Size SCH Outside Wall Temperature (°F) 100 200 300 400 500 600 650 700 750 Allowable Stress (psi) 16700 16700 16700 15500 14400 13500 13200 12900 12600 1″ 40 1.315 0.133 2205 2205 2205 2047 1902 1783 1743 1703 1664 80 1.315 0.179 3061 3061 3061 2841 2640 2475 2420 2365 2310 160 1.315 0.250 4493 4493 4493 4170 3874 3632 3552 3471 3390 1 1/2″ 40 1.900 0.145 1629 1629 1629 1512 1404 1317 1287 1258 1229 80 1.900 0.200 2303 2303 2303 2138 1986 1862 1821 1779 1738 160 1.900 0.281 3362 3362 3362 3120 2899 2717 2657 2597 2536 2″ 40 2.375 0.154 1371 1371 1371 1272 1182 1108 1083 1059 1034 80 2.375 0.218 1985 1985 1985 1843 1712 1605 1569 1534 1498 160 2.375 0.344 3283 3283 3283 3047 2831 2654 2595 2536 2477 3″ 40 3.500 0.216 1301 1301 1301 1208 1122 1052 1028 1005 982 80 3.500 0.300 1844 1844 1844 1712 1590 1491 1458 1425 1391 160 3.500 0.438 2787 2787 2787 2587 2403 2253 2203 2153 2103 4″ 40 4.500 0.237 1102 1102 1102 1023 950 891 871 851 831 80 4.500 0.337 1596 1596 1596 1482 1377 1291 1262 1233 1204 160 4.500 0.531 2611 2611 2611 2424 2552 2111 2064 2017 1970 5″ 40 5.563 0.258 965 965 965 896 832 780 763 746 728 80 5.563 0.375 1428 1428 1428 1325 1231 1154 1129 1103 1077 160 5.563 0.625 2474 2474 2474 2296 2133 2000 1955 1911 1866 6″ 40 6.625 0.280 877 877 877 814 756 709 693 677 661 80 6.625 0.432 1379 1379 1379 1280 1189 1115 1090 1065 1040 160 6.625 0.719 2382 2382 2382 2211 2054 1925 1883 1840 1797 8″ 40 8.625 0.322 771 771 771 716 665 623 610 596 582 80 8.625 0.500 1218 1218 1218 1131 1050 985 963 941 919 160 8.625 0.906 2298 2298 2298 2133 1982 1858 1817 1775 1734 10″ 40 10.750 0.365 699 699 699 649 603 565 553 540 528 80 10.750 0.594 1159 1159 1159 1075 999 937 916 895 874 160 10.750 1.125 2289 2289 2289 2124 1974 1850 1809 1768 1727

ASTM A312 Stainless Steel Pipe Tolerances OD Tolerance WTH, mm Length, mm 10.3 to 48.3 +0.40/-0.80 +/-12.5%t +6/-0 over 48.3 to 114.3 +0.80/-0.08 over 114.3 to 219.1 +1.60/-0.80 over 219.1 to 457.2 +2.40/-0.80 over 457.2 to 660.4 +3.20/-0.80 over 660.4 to 864 +4.00/-0.08 over 864 to 1219.2 +4.80/-0.08

Wall Thickness tolerance of ASTM A312 TP316Ti NPS Wall Thickness Tolerance, % 1/8 To 2-1/2 Incl., All T/D Ratios Over 20.2 Under 12.5 Over 3 To 18 Incl., T/D Up To 5% Incl. Over 22.5 Under 12.5 Over 3 To 18, Incl., T/D > 5% Over 15.0 Under 12.5 20 And Large, Welded, All T/D Ratios Over 17.5 Under 12.5 20 And Large, Seamless, T/D Up To 5% Incl. Over 22.5 Under 12.5 >20 And Large, Seamless, T/D > 5% Over 15.0 Under 12.5

Off-Shore Oil Drilling Companies

Power Generation

Petrochemicals

Gas Processing

Specialty Chemicals

Pharmaceuticals

Pharmaceutical Equipment

Chemical Equipment

Sea Water Equipment

Heat Exchangers

Condensers

Pulp and Paper Industry

Wenzhou Kaixin Kaixin Metal Co.,LTD

Wenzhou Kaixin Kaixin Metal Co.,LTD