ASTM A789 ASME SA 789 SAF2507 UNS S32750 (EN 10216–5 1.4410) Stainless Steel is super duplex stainless steel with 25% chromium, 4% molybdenum, Và 7% nickel designed for demanding applications which require exceptional strength and corrosion resistance, such as chemical process, petrochemical, and seawater equipment. The steel has excellent resistance to chloride stress corrosion cracking, high thermal conductivity, and a low coefficient of thermal expansion.

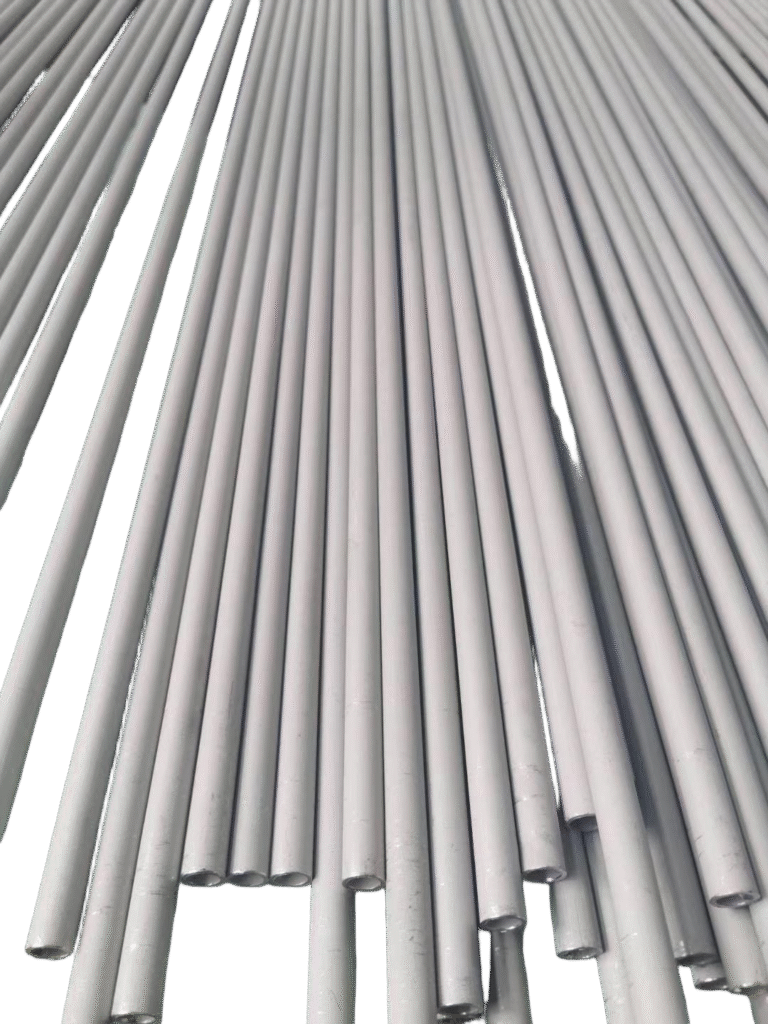

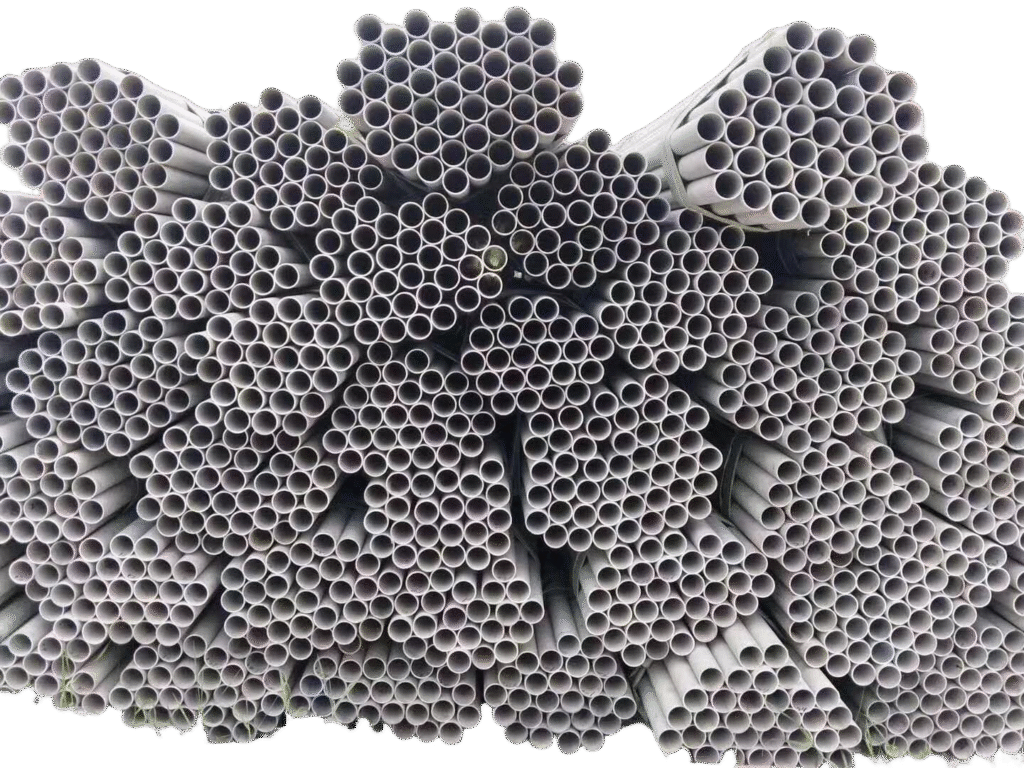

ASTM A789 Super Duplex Steel SAF 2507 Tube Specification :

Kích thước : ASTM, ASME and API

ASTM Specification : ASTM A790 / ASME SA790, ASTM A789 / ASME SA A789

ASTM A789 Super Duplex Steel SAF 2507 Tube Size : 1/2″NB TO 12 “NB IN

Seamless Pipe & Tube Size : 1/2” NB – 8” NB

Welded Pipe & Tube Size : 6” NB – 24” NB

Outer Diameter : 6.0-630mm

Độ dày : 0.5-45mm

Lịch trình : Sch20, Xương ức, Sch40, STD, Sch80

Kiểu : Liền mạch / Erw / Hàn / Bịa đặt / CDW

Hình thức : Round Pipe/Tube, Square Pipe/Tube, Rectangular Pipe/Tube, Coiled Tube, “U” Shape, Pan Cake Coils, Hydraulic Tube

Chiều dài : Đơn ngẫu nhiên, Gấp đôi ngẫu nhiên & Required Length

Kết thúc : Kết thúc đơn giản, Kết thúc vát, Threaded

ASTM A789-ASME SA789 SAF2507 Equivalent Material

| Hợp kim | UNS Designation | Werkstoff NR. | Thông số kỹ thuật | AFNOR | Cấp | TỪ | TRONG | Ss |

| 2507 | S32750 | 1.4410 | A/SA789, A/SA790 | Z3 CN 25.06 Az | F53 | X 2 Cr Ni MoN 25.7.4 | 1.4410 | 2328 |

ASTM A789 S32750 (SAF2507) Stainless Steel Tubes Chemical Composition

| C % | Và % | Mn % | P % | S % | Cr % | TRONG % | MO % | N % | Cu % |

| 0.03 Tối đa | 0.8 Tối đa | 1.2 Tối đa | 0.035 Tối đa | 0.02 Tối đa | 24.0-26.0 | 6.0-8.0 | 3.0-5.0 | 0.24-0.32 | 0.50 Tối đa |

Mechanical Properties

| 0.2% Proof Stress (N/mm2) [ksi] minimum | 550[79.8] |

| Ultimate Tensile Strength (N/mm2) [ksi] minimum | 800 [116] |

| Kéo dài (%) minimum | 25 |

| ardness (HBN) | 270 Tối đa |

| Reduction of Cross Section Area (%) | 45 |

| Charpy V-notch Impact at ambient Temp (J) [ft.lb] | 80Tối thiểu [59Tối thiểu] |

| Charpy V-notch Impact at -46°C (J) [ft.lb] | 45av, 35Tối thiểu [33av, 25.8Tối thiểu] |

Physical Properties

| Tỉ trọng (Kg.m-1) | 7810 |

| Magnetic Permeability | 33 |

| Young’s Modulus (N/mm2) | 199 x 103 |

| Specific Heat, 20° C. (J.Kg-1.°K-1) | 475 |

| Fracture Toughness, Kq (MPa.m) | 475 |

| Specific Electrical Resistance, 20° C. (µO.m) | 0.80 |

| Thermal conductivity, 20° C. (W.m-1.°K-1) | 14.2 |

| Mean coefficient of thermal expansion, 20-100° C. (°K-1) | 11.1 x 10-6 |

Pressure Rating of Super Duplex 2507 Tube

| Tube O.D. (In.) | Wall Thickness Of Pipe (Inch) | |||||||

| .028 | .035 | .049 | .065 | .083 | .095 | .109 | .120 | |

| Áp lực làm việc (Psig) | ||||||||

| 1/8 | 7900 | 10100 | ||||||

| 1/4 | 3700 | 4800 | 7000 | 9500 | ||||

| 5/16 | 3700 | 5400 | 7300 | |||||

| 3/8 | 3100 | 4400 | 6100 | |||||

| 1/2 | 2300 | 3200 | 4400 | |||||

| 3/4 | 2200 | 3000 | 4000 | 4600 | ||||

| 1 | 2200 | 2900 | 3400 | 3900 | 4300 | |||

Super Duplex 2507 Tubing Size chart

| Tường | Kích thước ( O.D.) |

| .010 | 1/16″ , 1/8″ , 3/16″ |

| .020 | 1/16″ , 1/8″ , 3/16″ , 1/4″ , 5/16″ , 3/8″ |

| .012 | 1/8″ |

| .016 | 1/8″ , 3/16″ |

| .028 | 1/8″ , 3/16″ , 1/4″ , 5/16″ , 3/8″ , 1/2″ , 3/4″ , 1″ , 1 1/2″ , 2″ |

| .035 | 1/8″ , 3/16″ , 1/4″ , 5/16″ , 3/8″ , 7/16″ , 1/2″ , 16″ , 5/8″ , 3/4″ , 7/8″ , 1″ , 1 1/4″ , 1 1/2″ , 1 5/8″ , 2″ , 2 1/4″ |

| .049 | 3/16″ , 1/4″ , 5/16″ , 3/8″ , 1/2″ , 16″ , 5/8″ , 3/4″ , 7/8″ , 1″ , 1 1/8″ , 1 1/4″ , 1 1/2″ , 1 5/8″ , 2″ , 2 1/4″ |

| .065 | 1/4″ , 5/16″ , 3/8″ , 1/2″ , 16″ , 5/8″ , 3/4″ , 7/8″ , 1″ , 1 1/4″ , 1 1/2″ , 1 5/8″ , 1 3/4″ , 2″ , 2 1/2″ , 3″ |

| .083 | 1/4″ , 3/8″ , 1/2″ , 5/8″ , 3/4″ , 7/8″ , 1″ , 1 1/4″ , 1 1/2″ , 1 5/8″ , 1 7/8″ , 2″ , 2 1/2″ ,3″ |

| .095 | 1/2″ , 5/8″ , 1″ , 1 1/4″ , 1 1/2″ , 2″ |

| .109 | 1/2″ , 3/4″ , 1″ , 1 1/4″ , 1 1/2″ , 2″ |

| .120 | 1/2″ , 5/8″ , 3/4″ , 7/8″ , 1″ , 1 1/4″ , 1 1/2″ , 2″ , 2 1/4″ , 2 1/2″ , 3″ |

| .125 | 3/4″ , 1″ , 1 1/4″ , 1 1/2″ , 2″ , 3″ , 3 1/4″ |

| .134 | 1″ |

| .250 | 3″ |

| .375 | 3 1/2″ |

Standard Tolerances of UNS S32750 Tube

Kích cỡ | Standard Tolerances | |||||

| Hình thức | Tường | CỦA | Length and/or coils | CỦA | Lengths | Tường |

| Subsea Umbilical Tubing (ASTM A789 & ASTM A790) | 0.039″ to 0.125″ | 3/8″ to 1-1/2″ | Cut lengths to 60′ Coils to 1-1/2″ OD* | ±0.005″ | Coils to 80,000′ (24,384 m) | ±10% |

| Pressure & Corrosion Tubing (ASTM A789) | 0.010″ – 0.220″ | 1/16″ – 4″ | Cut lengths up – 40′ Coils to 1-1/2″ CỦA | <1-1/2″ ±0.005″ 1-1/2″ to 3″ ±0.010″ 3-1/2″to 4″ ±0.015″ | Random Upto +2″ Cuts +1/8″ -0″ Coils to 80,000′ | ±10 |

Processing

Hot Forming

2507 should be hot worked between 1875 F and 2250 F. This should be followed by a solution anneal at 1925F minimum and a rapid air or water quench.

Cold Forming

Most of the common stainless steel forming methods can be used for cold working 2507. The alloy has a higher yield strength and lower ductility than the austenitic steels so fabricators may find that higher forming forces, increased radius of bending, and increased allowance for springback are necessary. Deep drawing, stretch forming, and similar processes are more difficult to perform on 2507 than on an austenitic stainless steel. When forming requires more than 10% cold deformation, a solution anneal and quench are recommended.

Điều trị nhiệt

2507 should be solution annealed and quenched after either hot or cold forming. Solution annealing should be done at a minimum of 1925 F. Annealing should be followed immediately by a rapid air or water quench. To obtain maximum corrosion resistance, heat treated products should be pickled and rinsed.

Applications

Electronics

Transport and traffic

Pulp and paper industry

Medicine

Fertilizers

Valve & Pumps

Petrochemical

Architecture and construction

Aerospace

Nuclear Power

Energy industry

Chemicals industry

Nickel Alloy in Pulp and Paper

Motor industry

Food and drink

304L stainless steel pipe 304L stainless steel seamless pipe 310S stainless steel pipes 321 Stainless steel 904L stainless steel pipe 904L stainless steel tubes 2205 2205 Ống thép không gỉ 2205 ống thép không gỉ liền mạch 2507 duplex stainless steel pipe 2507 Ống thép không gỉ 2507 ống thép không gỉ liền mạch 2520 stainless steel tubes AStm A312 stainless stael pipe Thông số kỹ thuật ống bằng thép không gỉ ASTM A312 ASTM A312 STAINLESS STEEL SEAMLESS PIPE ỐNG THÉP KHÔNG GỈ ASTM A312 TP304 ASTM A312 TP316L STAINLESS STEEl PIPE Astm a554 stainless steel pipe birmingham wire gauge BWG Bwg Sizes bwg tube duplex stainless steel pipe gauge bwg Nhiệt ống thở ra inox press fittings price sanitary seamless pipe sanitary stainless steel pipe sanitary stainless steel tubes Sizes Chart Ống thép không gỉ stainless steel pipefitting Ống thép không gỉ stainless steel sanitary tubes ống thép không gỉ liền mạch ống liền mạch bằng thép không gỉ Ống thép không gỉ stainless steel welded pipe standard wire gauge super austenitic 904L stainless steel pipe TP304 Ống thép không gỉ TP304L Stainless steel seamless pipe Tube China

Nhà cung cấp ống thép không gỉ Ôn Châu Kaixin Trung Quốc

Nhà cung cấp ống thép không gỉ Ôn Châu Kaixin Trung Quốc