Alloy Steel is steel that is alloyed with a variety of elements in total amounts between 1.0% Và 50% by weight to improve its mechanical properties. Alloy steels are broken down into two groups: low-alloy steels and high-alloy steels. The difference between the two is somewhat arbitrary: Smith and Hashemi define the difference at 4.0%, while Degarmo, et al., define it at 8.0%. Most commonly, the phrase “Alloy Steel ” refers to low-alloy steels. Strictly speaking, every steel is an alloy, but not all steels are called “alloy steels”. The simplest steels are iron (Fe) alloyed with carbon (C) (about 0.1% ĐẾN 1%, depending on type). Tuy nhiên, the term “Alloy Steel ” is the standard term referring to steels with other alloying elements added deliberately in addition to the carbon. Common alloyants include manganese (the most common one), nickel, chromium, molybdenum, vanadium, silicon, and boron. Less common alloyants include aluminum, cobalt, copper, cerium, niobium, titanium, tungsten, tin, zinc, lead and zirconium.

ASTM A335 P11 Specification

| ASME SA335 P11 Pipe Standard | ASTM A335 P11, SA335 P11 (with IBR Test Certificate) |

|---|---|

| ASTM A335 Grade P11 Pipe Size | 1/2"NB đến 36" NB |

| A335 Grade P11 Pipe Thickness | 3-12mm |

| ASME SA335 P11 Pipe Schedules | Sch 5, SK10, Sch 40, Sch 80, SCH 80S, Sch 160, Sch xxs, Sch XS, All Schedules |

| ASTM A335 Grade P11 Pipe Tolerance | Cold drawn pipe: +/-0.1mm

Cold rolled pipe: +/-0.05mm

|

| Craft | Cold rolled and Cold drawn |

| ASME SA335 P11 Pipe Type | Liền mạch / Erw / Hàn / Bịa đặt |

| A335 Grade P11 Pipe available in Form of | Hình chữ nhật, Tròn, Quảng trường, Thủy lực vv. |

| ASTM A335 Grade P11 Pipe Length | Tiêu chuẩn Double & In Cut length also. |

| ASME SA335 P11 Pipe End | Kết thúc vát,Kết thúc đơn giản, Bước đi |

| Specialized in | Large Diameter A335 Grade P11 Pipe |

| Additional Testing | NACE TM0284, NACE MR 0175, NACE TM0177, HIC TEST, SSC TEST, H2 SERVICE, IBR, vân vân. |

| Ứng dụng | Seamless Ferritic Alloy-Steel Pipe for High-Temperature Service |

| Alloy Steel P11 Pipe Origin | Trung Quốc |

ASTM A335 Grade P91 Alloy Steel Pipe Chemical Compositions :

| C, % | Mn, % | P, % | S, % | Và, % | Cr, % | MO, % | V, % | N, % | TRONG, % | Al, % | Nb, % |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.08-0.12 | 0.3-0.6 | 0.02 Tối đa | 0.01 Tối đa | 0.2-0.5 | 8.0-9.5 | 0.85-1.05 | 0.18-0.25 | 0.03-0.07 | 0.4 Tối đa | 0.04 Tối đa | 0.06-0.10 |

Alloy Steel P91 Seamless Pipes Mechanical Properties :

| Độ bền kéo , MPA | Sức mạnh năng suất, MPA | Kéo dài, % | Hardness, HB |

|---|---|---|---|

| 585 Tối thiểu | 415 Tối thiểu | 20 Tối thiểu | 250 Tối đa |

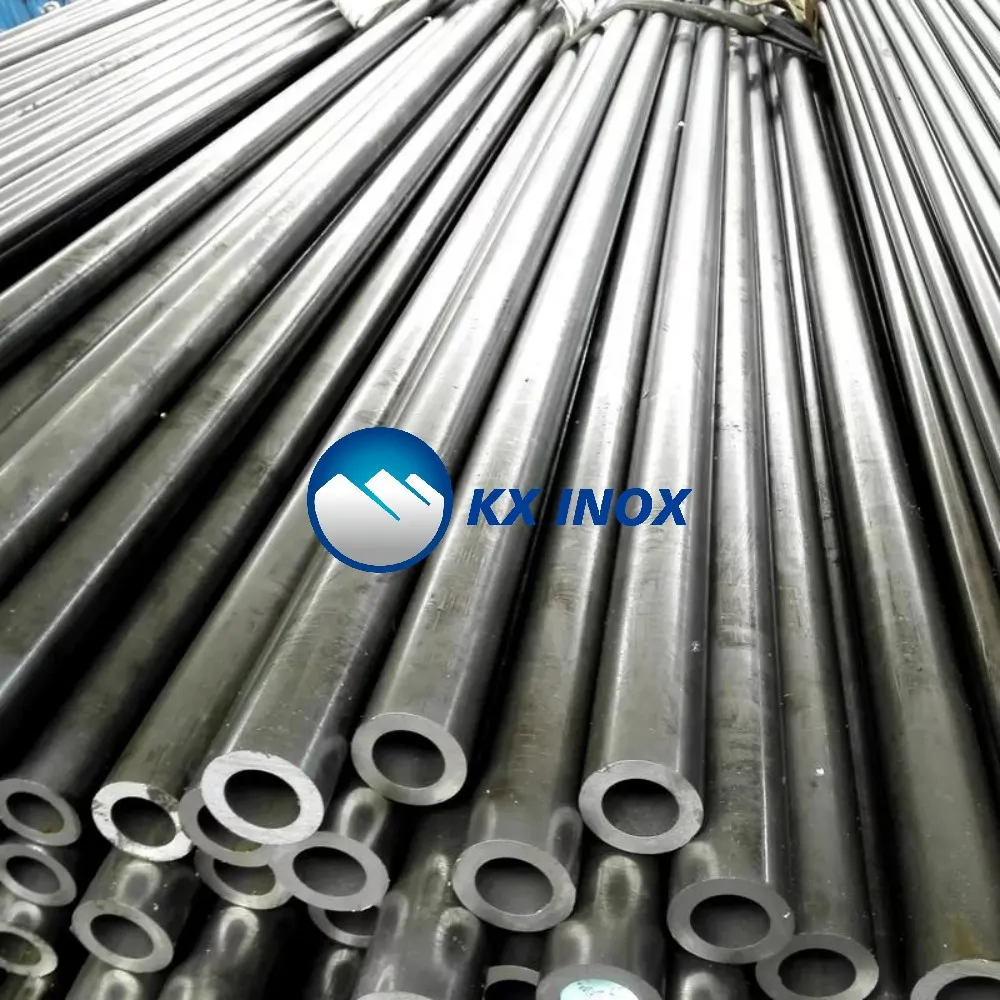

ASME SA335 P11 Seamless Pipes

Standard Specification for Seamless Carbon Steel Pipe for High-Temperature Service

This specification2 covers nominal wall and minimum wall seamless ferritic alloy-steel pipe intended for high temperature service. Pipe ordered to this specification shall be suitable for bending, flanging (vanstoning), and similar forming operations, and for fusion welding. Selection will depend upon design, service conditions, Mechanical Properties, and high-temperature characteristics.

ASTM A335 Pipe (ASME S/A335, Chorme-Moly) is a seamless ferritic Alloy-Steel Pipe for high temperature service. Pipe ordered to this specification shall be suitable for bending, flanging (vanstoning), and similar forming operations, and for fusion welding. Sometimes referred to as “P Grade”, Chrome Moly Pipe is popular in Stainless Steel Tubes P-Grades P5, P9, P11, P22, and P91. The most common use of grades P11, P22, and P91 is in the power industry and petro-chemical plants, Grades P5 and P9 are commonly used in refineries.

A335 is often called chrome moly pipe because of the chemical makeup of Molybdenum (MO) and Chromium (Cr). Molybdenum increases the strength of steel as well as the elastic limit, resistance to wear, impact qualities, and hardenability. Moly increases the resistance to softening, restrains grain growth and makes chromium steel less susceptible to embrittlement. Moly is the most effective single additive that increases high temperature creep strength. It also enhances the corrosion resistance of steel, and inhibits pitting. Crom (or chrome) is the essential constituent of Stainless Steel. Any steel with 12% or more Chrome is considered stainless. Chrome is virtually irreplaceable in resisting oxidation at elevated temperatures. Chrome raises the tensile, yield, and P11 Material Hardness value at room temperatures. The composition chrome moly Alloy Steel pipe and Alloy Steel Tubes make it ideal for use in power plants, refineries, petro chemical plants, and oil field services where fluids and gases are transported at extremely high temperatures and pressures.

Công ty kim loại Wenzhou Kaixin Kaixin, Ltd

Công ty kim loại Wenzhou Kaixin Kaixin, Ltd