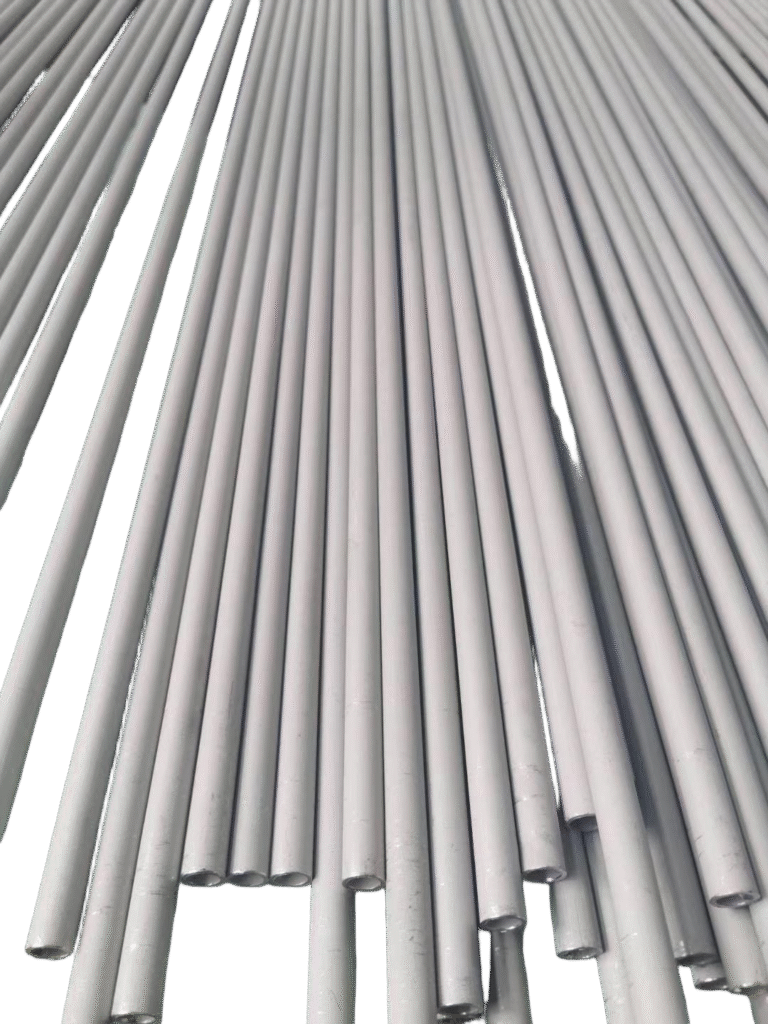

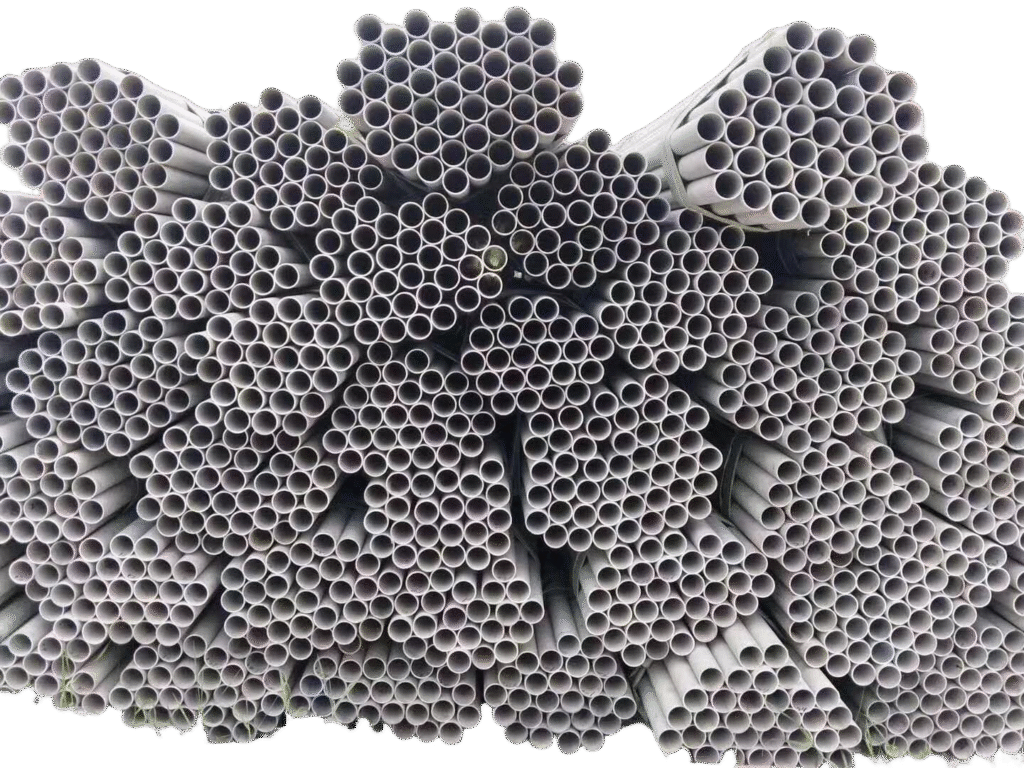

ASTM A312 TP304 Stainless steel seamless pipe is an austenitic alloy grade designed with a superior composition of nickel and chromium. 这 ASTM A312 TP304 alloy has excellent resistance against corrosive and oxidative media across stress-induced environments. The versatile grade of alloys has outstanding mechanical properties. They have a minimum tensile strength of 75ksi with a minimum yield strength of 30Ksi. 这 ASTM A312 Grade TP304 Seamless Pipe can be processed via the hot or cold rolling process. These pipes can be availed in thickness between 0.8mm up to 12mm and can be availed in different sizes and dimensions to meet project requirements.

The components in this grade are produced in seamless, 焊接的, and ERW configurations. Each of these modules has its own set of features allowing them to be used in different applications. 这 美国机械工程师学会 312 TP 304 Seamless Pipe is produced via an extrusion process wherein hot steel billets are passed through the metal. ASTM A312 TP304 Stainless steel seamless pipe allows the material the capability to work in high temperatures and pressures. More over these pipes are slightly expensive as compared to welded pipes.

Equivalent of ASTM A312 TP304 Seamless Pipe

Equivalent 年级

| 年级 | 我们 | 在 | 他 | AFNOR | 学士 | 材料编号. | 国家标准 | SS |

| UNDER | 美国 | EUROPE | JAPAN | RUSSIAN | BRITISH | GERMAN | RUSSIAN | SWEDISH |

| ASTM A312 TP 304 | S30400 | X5CrNi18-10 | SUS 304 | Z7CN18‐09 | 304S31 | 1.4301 | 08Х18Н10 | 2332 |

ASTM A312 TP304 stainless steel chemical composition

化学成分

| 年级 | C | 锰 | 磷 | S | 和 | 在 | 铬 | 铁 |

| TP304 | 0.08 | 2.00 | 0.045 | 0.030 | 1.0 | 8-11 | 18-20 | 巴尔. |

ASTM A312 TP304 stainless steel mechanical properties

Mechanical properties chart

| 抗拉强度(兆帕) MaxYield point(兆帕) 最大限度 | 伸长(%) | 硬度 (HRB) 最大限度 | ||||

| TP304 | 515 | 205 | 35 | 92 | ||

SS 304 Seamless Pipes Physical Properties

Physical Properties Chart

| rade | 密度 (公斤/立方米) | Specific Heat 0-1000C (焦耳/公斤.K) | 弹性模量 (GPa) | 平均热膨胀系数 (m/m/0C) | 导热系数 (瓦/米·K) | 电阻率 (n.m) | |||

| 0-100℃ | 0-315℃ | 0-538℃ | 100°C 时 | 500°C 时 | |||||

| 304 | 8000 | 500 | 193 | 17.2 | 17.8 | 18.4 | 16.2 | 21.5 | 720 |

ASTM A312 TP304 Seamless Pipe Schedule Chart

Schedule Change to inch/mm Chart

| 公称管道尺寸 (核动力源) | STD SCH 40S | SCH 0S | SCH 120 | XS SCH 80S | XXS | 外径 (毫米) | SCH 160 |

| 1/8″ | 1.073 0.037 | 2.041 0.048 | 10.029 | ||||

| 1/4″ | 2.024 0.064 | 1.065 0.048 | 3.002 0.081 | 13.072 | |||

| 3/8″ | 2.031 0.086 | 1.065 0.064 | 3.020 1.012 | 17.015 | |||

| 1/2″ | 2.077 1.029 | 2.011 1.001 | 3.073 1.064 | 7.047 2.065 | 21.034 | 4.076 1.098 | |

| 3/4″ | 2.087 1.071 | 2.011 1.030 | 3.091 2.023 | 7.082 3.069 | 26.067 | 5.056 2.094 | |

| 1″ | 3.038 2.054 | 2.077 2.012 | 4.055 3.028 | 9.009 5.075 | 33.040 | 6.035 4.030 | |

| 1 1/4″ | 3.056 3.043 | 2.077 2.073 | 4.085 3.053 | 9.070 7.088 | 42.016 | 6.035 5.069 | |

| 1 1/2″ | 3.068 3.011 | 2.077 3.015 | 5.008 5.049 | 10.016 9.069 | 48.026 | 7.014 7.034 | |

| 2″ | 3.091 5.052 | 2.077 3.098 | 5.054 7.059 | 11.007 13.065 | 60.033 | 8.074 11.028 | |

| 2 1/2″ | 5.016 8.076 | 3.005 5.034 | 7.001 11.058 | 73.003 | 9.053 15.014 | ||

| 3″ | 5.049 11.045 | 3.005 6.054 | 7.062 15.050 | 15.024 28.009 | 88.090 | 11.013 21.065 | |

| 3 1/2″ | 5.074 13.077 | 3.005 7.052 | 8.008 18.090 | 101.060 | |||

| 4″ | 6.002 16.031 | 3.005 8.048 | 11.013 28.032 | 8.056 22.065 | 17.012 41.063 | 114.030 | 13.049 34.002 |

| 5″ | 6.055 22.010 | 3.040 11.074 | 9.052 31.041 | 141.060 | 15.088 49.083 | ||

| 6″ | 7.011 28.068 | 3.040 14.004 | 14.027 54.020 | 10.097 43.019 | 21.095 80.036 | 168.026 | 18.026 68.056 |

| 8″ | 8.018 43.016 | 3.076 20.025 | 23.001 112.090 | 12.070 65.059 | 219.008 | 18.026 90.044 | |

| 10″ | 9.027 61.020 | 4.019 28.020 | 12.070 81.055 | 273.005 | 28.058 174.082 | ||

| 12″ | 9.053 74.092 | 4.057 36.053 | 323.085 | 12.070 97.046 |

美国机械工程师学会 312 TP 304 Pipes Weight Chart

| PIPE SIZE | OD IN INCHES | A.S.A. Pipe Schedules | |||||||||||

| 5s | 5 | 10s | 10 | 40s & 标准. | 40 | 60 | 80s & E·H. | 80 | 120 | 160 | DBL E.H. | ||

| 1/8 | .405 | .035.1383 | .049.1863 | .049.1863 | .068.2447 | 068.2447 | 0.95.3145 | 0.95.3145 | |||||

| 1/4 | .540 | .049.2570 | .065.3297 | .065.3297 | .088.4248 | 088.4248 | .119.5351 | .119.5351 | |||||

| 3/8 | .675 | .049.3276 | .065.4235 | .065.4235 | .091.5676 | .091.5676 | .126.7338 | .126.7338 | |||||

| 1/2 | .840 | .065.5383 | .065.5383 | .083.6710 | .083.6710 | .109.8510 | .109.8510 | .1471.088 | .1471.088 | .1871.304 | .2941.714 | ||

| 3/4 | 1.050 | .065.6838 | .065.6838 | .083.8572 | .083.8572 | .1131.131 | .1131.131 | .1541.474 | .1541.474 | .2181.937 | .3082.441 | ||

| 1 | 1.315 | .065.8678 | .065.8678 | .1091.404 | .1091.404 | .1331.679 | .1331.679 | .1792.172 | .1792.172 | .2502.844 | .3583.659 | ||

| 1-1/4 | 1.660 | .0651.107 | .0651.107 | .1091.806 | .1091.806 | .1402.273 | .1402.273 | .1912.997 | .1912.997 | .2503.765 | .3825.214 | ||

| 1-1/2 | 1.900 | .0651.274 | .0651.274 | .1092.085 | .1092.085 | .1452.718 | .1452.718 | .2003.631 | .2003.631 | .2814.859 | .4006.408 | ||

| 2 | 2.375 | .0651.604 | .0651.604 | .1092.638 | .1092.638 | .1543.653 | .1543.653 | .2185.022 | .2185.022 | .3437.444 | .4369.029 | ||

| 2-1/2 | 2.875 | .0832.475 | .0832.475 | .1203.531 | .1203.531 | .2035.793 | .2035.793 | .2767.661 | .2767.661 | .37510.01 | .55213.70 | ||

| 3 | 3.500 | .0833.029 | .0833.029 | .1204.332 | .1204.332 | .2167.576 | .2167.576 | .30010.25 | .30010.25 | .43714.32 | .60018.58 | ||

| 3-1/2 | 4.000 | .0833.472 | .0833.472 | .1204.973 | .1204.973 | .2269.109 | .2269.109 | .31812.51 | .31812.51 | .63622.85 | |||

| 4 | 4.500 | .0833.915 | .0833.915 | .1205.613 | .1205.613 | .23710.79 | .23710.79 | .28112.66 | .33714.98 | .33714.98 | .43719.01 | .53122.51 | .67427.54 |

| 4-1/2 | 5.000 | .24712.53 | .35517.61 | .71032.53 | |||||||||

| 5 | 5.563 | .1096.349 | .1096.349 | .1347.770 | .1347.770 | .25814.62 | .25814.62 | .37520.78 | .37520.78 | .50027.04 | .62532.96 | .75038.55 | |

| 6 | 6.625 | .1097.585 | .1097.585 | .1349.290 | .1349.290 | .28018.97 | .28018.97 | .43228.57 | .43228.57 | .56236.39 | .71845.30 | .86453.16 | |

| 7 | 7.625 | .30123.57 | .50038.05 | .87563.08 | |||||||||

| Medium Type = Wall thickness in inches Bold Type = Steel weight per foot in pounds | |||||||||||||

Mostly TP304 stainless steel pipe pressure rating

Stainless Steel Pipes – 压力等级

Pressure ratings for standard seamless A312-TP304 stainless steel pipes – temperatures 100°F to 750°F

Ratings for standard seamless stainless steel pipes, temperatures from 100°F to 750°F. All ratings in psig based on ANSI/ASME B 31.1.

Pressure Rating (psig)

| 管道尺寸 (英寸) | Pipe Schedule | 温度 (华氏度) | ||||||||

| 100 | 200 | 300 | 400 | 500 | 600 | 650 | 700 | 750 | ||

| 1″ | 40 | 3048 | 2629 | 2362 | 2171 | 2019 | 1924 | 1867 | 1824 | 1810 |

| 1″ | 80 | 4213 | 3634 | 3265 | 3002 | 2791 | 2659 | 2580 | 2528 | 2501 |

| 1″ | 160 | 6140 | 5296 | 4759 | 4375 | 4068 | 3876 | 3761 | 3684 | 3646 |

| 1.5″ | 40 | 2257 | 1947 | 1750 | 1608 | 1496 | 1425 | 1383 | 1354 | 1340 |

| 1.5″ | 80 | 3182 | 2744 | 2466 | 2267 | 2108 | 2009 | 1949 | 1909 | 1889 |

| 1.5″ | 160 | 4619 | 3984 | 3580 | 3291 | 3060 | 2916 | 2829 | 2772 | 2743 |

| 2″ | 40 | 1902 | 1640 | 1474 | 1355 | 1260 | 1201 | 1165 | 1141 | 1129 |

| 2″ | 80 | 2747 | 2369 | 2129 | 1957 | 1820 | 1734 | 1682 | 1648 | 1631 |

| 2″ | 160 | 4499 | 3880 | 3486 | 3205 | 2980 | 2840 | 2755 | 2699 | 2671 |

| 3″ | 40 | 1806 | 1558 | 1400 | 1287 | 1196 | 1140 | 1106 | 1084 | 1072 |

| 3″ | 80 | 2553 | 2202 | 1979 | 1819 | 1691 | 1612 | 1564 | 1532 | 1516 |

| 3″ | 160 | 3840 | 3312 | 2976 | 2736 | 2544 | 2424 | 2352 | 2304 | 2280 |

| 4″ | 40 | 1531 | 1321 | 1187 | 1091 | 1014 | 967 | 938 | 919 | 909 |

| 4″ | 80 | 2213 | 1909 | 1715 | 1577 | 1466 | 1397 | 1355 | 1328 | 1314 |

| 4″ | 160 | 3601 | 3106 | 2791 | 2566 | 2386 | 2273 | 2206 | 2161 | 2138 |

| 5″ | 40 | 1342 | 1158 | 1040 | 956 | 889 | 847 | 822 | 805 | 797 |

| 5″ | 80 | 1981 | 1709 | 1535 | 1411 | 1312 | 1250 | 1213 | 1189 | 1176 |

| 5″ | 160 | 3414 | 2945 | 2646 | 2433 | 2262 | 2155 | 2091 | 2049 | 2027 |

| 6″ | 40 | 1219 | 1052 | 945 | 869 | 808 | 770 | 747 | 732 | 724 |

| 6″ | 80 | 1913 | 1650 | 1483 | 1363 | 1267 | 1208 | 1172 | 1148 | 1136 |

| 6″ | 160 | 3289 | 2836 | 2549 | 2343 | 2179 | 2076 | 2014 | 1973 | 1953 |

| 8″ | 40 | 1073 | 926 | 832 | 765 | 711 | 678 | 657 | 644 | 637 |

| 8″ | 80 | 1692 | 1459 | 1311 | 1205 | 1121 | 1068 | 1036 | 1015 | 1005 |

| 8″ | 160 | 3175 | 2738 | 2460 | 2262 | 2103 | 2004 | 1944 | 1905 | 1885 |

| 10″ | 40 | 974 | 840 | 755 | 694 | 945 | 615 | 596 | 584 | 578 |

| 10″ | 80 | 1609 | 1388 | 1247 | 1147 | 1066 | 1016 | 986 | 966 | 956 |

| 10″ | 160 | 3147 | 2714 | 2439 | 2242 | 2085 | 1986 | 1927 | 1880 | 1868 |

304 stainless steel Pipe Outside Diameter Tolerance

| 核动力源 | ASTM A312 OD Tolerance | |||

| + | – | |||

| 英寸 | 毫米 | 英寸 | 毫米 | |

| 1/8〜1 1 /2 | 1/64(0.015) | 0.4 | 1/32(0.031) | 0.8 |

| > 1 1 /2〜4 | 1/32(0.031) | 0.8 | 1/32(0.031) | 0.8 |

| > 4〜8 | 1/16(0.062) | 1.6 | 1/32(0.031) | 0.8 |

| > 8〜18 | 3/32(0.093) | 2.4 | 1/32(0.031) | 0.8 |

| > 18〜26 | 1/8(0.125) | 3.2 | 1/32(0.031) | 0.8 |

| > 26〜34 | 5/32(0.156) | 4 | 1/32(0.031) | 0.8 |

| > 34〜48 | 3/16(0.187) | 4.8 | 1/32(0.031) | 0.8 |

Astm A312 Tp304 Pipe Processing

| ASTM A312 TP304 Stainless steel seamless pipe manufacture Processing | |

| Structural Cutting | Products cut include tube, 管道, Square tubes, Rectangular tubes, round tubes Thickness range is 1/8″NB TO 30″NB diameter |

| Tubular Cutting | Products cut include Ornamental Tube, Tubing and Hollow Section. Thickness range is 1/8″NB TO 30″NB diameter |

| Production Cutting | can provide production cutting for product diameters up to 4″. We utilize Amada Production Equipment to achieve these precision cuts with tight tolerances. |

| Structural Polishing | Products polished included all tubular products, with OD & ID polishing available |

热处理

Stainless steel pipes made of austenitic stainless steel ASTM A312 TP304 or TP304L shall be solution annealed. ASTM A312 TP304 Stainless steel seamless pipe During annealing, the pipes shall be heated to the temperature no less than 1900°F [1040℃] and soak at the temperature for a period long enough so that all chromium carbides are dissolved. Since the chromium carbide dissolves slowly, the highest practical temperature consistent with limited grain growth should be selected. This temperature is in the vicinity of 1095° [2000华氏度]. Complete dissolution of chromium carbides reduces precipitation of intergranular carbides hence improves the resistance to intergranular corrosion. Subsequent cooling (quenching) from the annealing temperature must be fast, thus ensuring that dissolved carbides remain in solution.

SA 312 组 304 Seamless Pipe Applications

药品

化学品

食品加工

Oil and Gas Processing

Energy industries

纸浆和造纸

Textile Machinery

Power Plants

建造

Automotive Industry

- ISO9001 ASTM A312 TP321 Stainless steel seamless pipe

- DNV ASTM A312 TP310S Stainless steel seamless pipe

- Bis Certified Ss 304 Seamless Pipes Best Price Supplier

- ASTM A312 TP304 Stainless steel seamless pipe manufacturer

- Storage For ASTM A312 TP317L Stainless steel seamless pipe

304L stainless steel pipe 304L不锈钢无缝管 310S stainless steel pipes 321 不锈钢 904L stainless steel pipe 904L stainless steel tubes 2205 2205 不锈钢管 2205 不锈钢无缝管 2507 双相不锈钢管 2507 不锈钢管 2507 不锈钢无缝管 2520 stainless steel tubes AStm A312 stainless stael pipe ASTM A312不锈钢管道规格 ASTM A312 STAINLESS STEEL SEAMLESS PIPE ASTM A312 TP304 不锈钢无缝管 ASTM A312 TP316L STAINLESS STEEl PIPE Astm a554 stainless steel pipe birmingham wire gauge 生物工作组 Bwg Sizes bwg tube 双相不锈钢管 gauge bwg 热交换管 inox press fittings 价格 sanitary seamless pipe 卫生级不锈钢管 sanitary stainless steel tubes Sizes Chart 不锈钢管 stainless steel pipefitting 不锈钢管 stainless steel sanitary tubes 不锈钢无缝管 不锈钢无缝管 不锈钢管 不锈钢焊管 standard wire gauge 超级奥氏体904L不锈钢管 TP304不锈钢管 TP304L Stainless steel seamless pipe 管材中国

不锈钢管供应商温州凯信中国

不锈钢管供应商温州凯信中国