ASTM A790 stainless steel duplex seamless pipes are essential in many industries. They offer a unique blend of strength and corrosion resistance. These pipes are crafted to meet high standards, ensuring reliability in demanding environments.

Duplex stainless steel combines the best of ferritic and austenitic stainless steels. This combination results in superior performance, especially in harsh conditions. The seamless design of these pipes ensures uniformity and strength.

Engineers and construction professionals often choose ASTM A790 pipes for their projects. Their high yield strength and resistance to stress corrosion make them ideal for various applications. From chemical processing to marine environments, these pipes deliver exceptional performance.

Understanding the properties and benefits of ASTM A790 pipes is crucial. This guide will provide detailed insights into their applications and standards. Whether you’re in procurement or engineering, this information will help you make informed decisions.

Understanding ASTM A790 Standard

The ASTM A790 standard is vital for industries using stainless steel pipes. It specifies requirements for seamless and welded pipes. This ensures pipes meet high mechanical and chemical property standards.

The standard covers duplex stainless steel, known for its robust characteristics. These characteristics include high strength and excellent corrosion resistance. Such traits make them suitable for challenging applications.

The ASTM A790 standard includes specifications for multiple grades. Common ones include UNS S31803 and UNS S32205. Each grade offers unique mechanical properties tailored to specific needs.

Key aspects defined by ASTM A790 include:

- Material Composition: Ensures consistency in nickel and molybdenum content.

- Mehanske lastnosti: Specifies tensile strength, yield strength, and elongation.

- Testing Requirements: Outlines necessary quality assurance tests.

These specifications allow for predictable performance. Industries rely on these standards for compatibility and safety. Following ASTM A790 helps ensure the pipes will perform reliably in harsh environments. It’s crucial for engineers to understand these standards when selecting piping solutions

These qualities make it a popular choice in construction and industrial applications. Duplex stainless steel provides the reliability needed for many industry sectors.

Key Properties of ASTM A790 Stainless Steel Duplex Seamless Pipe

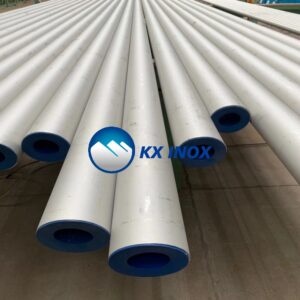

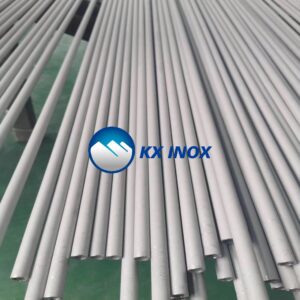

ASTM A790 stainless steel duplex seamless pipes are known for their remarkable properties. These pipes excel in both mechanical strength and corrosion resistance. This dual quality makes them versatile across various industries.

The seamless structure of these pipes ensures uniform strength. It eliminates weaknesses often found in welded joints. This feature contributes to their longevity and reliability in high-stress environments.

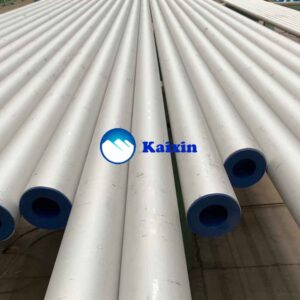

A significant advantage of these pipes is their high yield strength. With superior strength-to-weight ratios, they effectively support structural applications. This makes them ideal for industries like oil and gas, where high pressure is a concern.

ASTM A790 pipes also offer excellent resistance to stress corrosion cracking. This is particularly advantageous in chloride-rich environments, like marine settings. Their pitting resistance further enhances their durability against localized corrosion.

Key properties of ASTM A790 stainless steel duplex seamless pipes include:

- High Yield Strength: Ensures performance under pressure.

- Odpornost proti koroziji: Guards against various types of corrosion.

- Seamless Construction: Ensures uniformity and flawlessness.

- Durability: Offers long service life.

- Versatility: Compatible with diverse industrial applications.

These distinct properties make ASTM A790 pipes a preferred choice for demanding industrial applications. Their robust features ensure operational efficiency and safety.

Grades and Specifications Covered by ASTM A790

ASTM A790 standard covers several grades of duplex stainless steel. These grades offer different balances of performance traits. Key considerations include corrosion resistance, strength, and weldability.

Among the grades covered, UNS S31803 and UNS S32205 are prominent. These grades are widely used across various industries. They are known for their excellent resistance to corrosion and their strength.

The standard ensures that each grade meets specific chemical compositions and mechanical properties. This rigorous set of requirements ensures the pipe’s reliability. Compliance with these standards guarantees high-quality and uniform performance.

Grades covered by ASTM A790 include:

- UNS S31803: Offers balanced strength and corrosion resistance.

- UNS S32205: Enhanced resistance to corrosion and higher strength.

- Various Other Grades: Suited to different industrial needs.

These specifications are crucial for ensuring the appropriate selection for specific applications. They help match the pipe’s capabilities with the environmental demands of the application.

Manufacturing Process: Seamless vs. Welded Duplex Pipes

The manufacturing process of duplex stainless steel pipes greatly affects their properties. There are two primary types: seamless and welded. Each has unique advantages depending on the application.

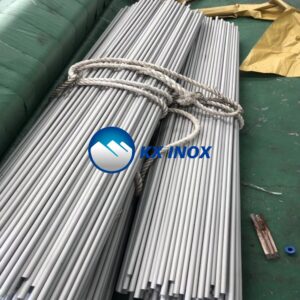

Seamless pipes are manufactured without a seam or weld. This process involves extrusion, making the pipe from a single solid billet. These pipes are known for their uniform strength and structure. They are less prone to defects.

Wenzhou Kaixin Kaixin Metal Co., Ltd

Wenzhou Kaixin Kaixin Metal Co., Ltd