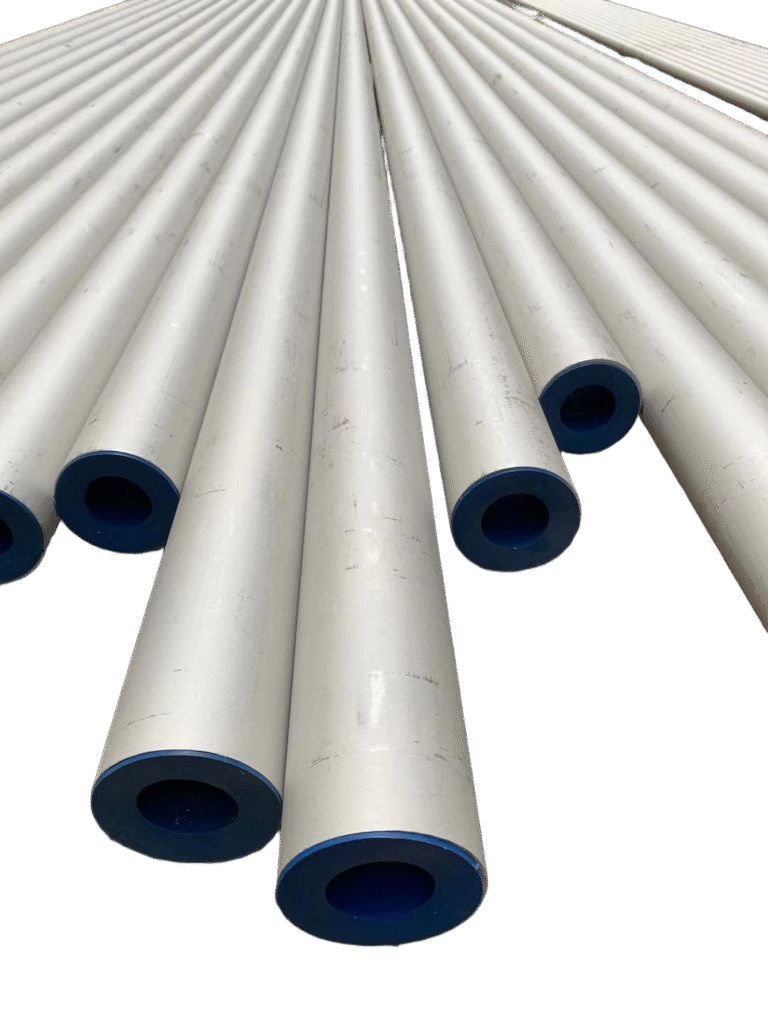

As we all know ASTM A312 TP321 Seamless Pipe is one of the most popular austenitic stainless steel pipe for high-temperature and general corrosive service. It can be used in many industries like oil and gas, water, mineral slurry transmission and structural purposes.

A312 TP321 Seamless Pipe often referred to as a marine grade stainless steel because of its effective resistance to chloride corrosion in comparison to other grades. It is an austenitic grade pipe with the addition of 2-3% molybdenum which further improves corrosion resistance.

321 Stainless Steel Seamless Pipes Specification

| Specificaties | ASTM A312 / SA 312 |

| Afmetingen | ASTM, ASME en API |

| Maat | 1/8″NB TO 30″NB IN |

| Naadloos 321 Pipes | 1/2″ Let op – 16″ Let op |

| Schema | SCH20, SCH30, SCH40, SOA, SCH80, XS, SCH60, SCH80, SCH120, SCH140, SCH160, XXS |

| Type | ASTM A 312 TP 321 Seamless Pipes |

| Gespecialiseerd in | Grote diameter |

| Lengte | Single Random, Double Random & Cut Length. |

| Formulier | Round, Square, Rectangular, Hydraulic Etc |

| End | Plain End, Beveled End, Treaded |

Roestvrij staal 321 Seamless Pipe Equivalent

| Cijfer | UNS No | Old British | Euronorm | Swedish SS | Japanese JIS | ||

| BS | En | Nee | Naam | ||||

| 321 | S32100 | 321S31 | 58B, 58C | 1.4541 | X6CrNiTi18-10 | 2337 | SUS 321 |

ASTM A312 321 Chemical Composition

| C | Mn | En | P | S | Cr | In |

| 0.08 | 2.00 | 1.00 | 0.045 | 0.030 | 17.0-19.0 | 9.0-12.0 |

ASTM A312 321 Mechanische eigenschappen

| Treksterkte | Opbrengststerkte | Verlenging |

| 515 (MPa) min | 205 (MPa) min | 40 (% ) min |

Physical Properties of ASTM A312 TP 321 Roestvrij stalen naadloze buis

| Cijfer | Dikte (kg/m3) | Elastic Modulus (GPa) | Mean Coefficient of Thermal Expansion (m/m/0C) | Thermische geleidbaarheid (W/m.K) | |||

| 0-1000C | 0-3150C | 0-5380C | at 1000C | at 5000C | |||

| 321 | 8027 | 193 | 16.6 | 17.2 | 18.6 | 16.1 | 22.2 |

Stainless Steel ASTM A312 TP321 Pipe Sizes

| NPS | VAN | SCH 5S | SCH 10S | SCH 40S | SCH-jaren 80 |

| 1/4 | 13.72 | – | 1.65 | 2.24 | 3.02 |

| 3/8 | 17.15 | – | 1.65 | 2.31 | 3.2 |

| 1/2 | 21.34 | 1.65 | 2.11 | 2.77 | 3.73 |

| 3/4 | 26.67 | 1.65 | 2.11 | 2.87 | 3.91 |

| 1 | 33.4 | 1.65 | 2.77 | 3.38 | 4.55 |

| 1.25 | 42.16 | 1.65 | 2.77 | 3.56 | 4.85 |

| 1.5 | 48.26 | 1.65 | 2.77 | 3.68 | 5.08 |

| 2 | 60.33 | 1.65 | 2.77 | 3.91 | 5.54 |

| 2.5 | 73.03 | 2.11 | 3.05 | 5.16 | 7.01 |

| 3 | 88.9 | 2.11 | 3.05 | 5.49 | 7.62 |

| 3.5 | 101.6 | 2.11 | 3.05 | 5.74 | 8.08 |

| 4 | 114.3 | 2.11 | 3.05 | 6.02 | 8.56 |

| 5 | 141.3 | 2.77 | 3.4 | 6.55 | 9.53 |

| 6 | 168.28 | 2.77 | 3.4 | 7.11 | 10.97 |

| 8 | 219.08 | 2.77 | 3.76 | 8.18 | 12.7 |

| 10 | 273.05 | 3.4 | 4.19 | 9.27 | 12.7 |

| 12 | 323.85 | 3.96 | 4.57 | 9.53 | 12.7 |

| 14 | 355.6 | 3.96 | 4.78 | 9.53 | 12.7 |

| 16 | 406.4 | 4.19 | 4.78 | 9.53 | 12.7 |

| 18 | 457.2 | 4.19 | 4.78 | 9.53 | 12.7 |

| 20 | 508 | 4.78 | 5.54 | 9.53 | 12.7 |

| 22 | 558.8 | 4.78 | 5.54 | – | – |

| 24 | 609.6 | 5.54 | 6.35 | 9.53 | 12.7 |

| 26 | 660.4 | – | – | – | – |

| 28 | 711.2 | – | – | – | – |

| 30 | 762 | 6.35 | 7.92 | – | – |

ASTM A312 SS 321 Seamless Pipe Tolerances

| NPS | ASTM A312 TP321 OD Tolerance | |||

| + | – | |||

| inch | mm | inch | mm | |

| 1/8~1 1 /2 > 1 1 /2~4 > 4~8 > 8~18 > 18~26 > 26~34 > 34~48 | 1/64(0.015) 1/32(0.031) 1/16(0.062) 3/32(0.093) 1/8(0.125) 5/32(0.156) 3/16(0.187) | 0.4 0.8 1.6 2.4 3.2 4.0 4.8 | 1/32(0.031) 1/32(0.031) 1/32(0.031) 1/32(0.031) 1/32(0.031) 1/32(0.031) 1/32(0.031) | 0.8 0.8 0.8 0.8 0.8 0.8 0.8 |

Wall Thickness Tolerance of ASTM A312 TP321 SS Seamless Pipe

| NPS | ASTM A312 TP321 WT Tolerance | |

| + | – | |

| 1/8-2 1/2 | 20 | 12.5 |

| 3-18,T/D≤5% | 22.5 | 12.5 |

| 3-18,T/D>5% | 15 | 12.5 |

| ≥20,gelast | 17.5 | 12.5 |

| ≥20,seamless,T/D≤5% | 22.5 | 12.5 |

| ≥20,seamless,T/D>5% | 15 | 12.5 |

321 Stainless Steel Pipe pressure rating

| Pipe Size (inches) | Pipe Schedule | Temperature (°F) | ||||||||

| 100 | 200 | 300 | 400 | 500 | 600 | 650 | 700 | 750 | ||

| 1″ | 40 | 3048 | 2629 | 2362 | 2171 | 2019 | 1924 | 1867 | 1824 | 1810 |

| 1″ | 80 | 4213 | 3634 | 3265 | 3002 | 2791 | 2659 | 2580 | 2528 | 2501 |

| 1″ | 160 | 6140 | 5296 | 4759 | 4375 | 4068 | 3876 | 3761 | 3684 | 3646 |

| 1.5″ | 40 | 2257 | 1947 | 1750 | 1608 | 1496 | 1425 | 1383 | 1354 | 1340 |

| 1.5″ | 80 | 3182 | 2744 | 2466 | 2267 | 2108 | 2009 | 1949 | 1909 | 1889 |

| 1.5″ | 160 | 4619 | 3984 | 3580 | 3291 | 3060 | 2916 | 2829 | 2772 | 2743 |

| 2″ | 40 | 1902 | 1640 | 1474 | 1355 | 1260 | 1201 | 1165 | 1141 | 1129 |

| 2″ | 80 | 2747 | 2369 | 2129 | 1957 | 1820 | 1734 | 1682 | 1648 | 1631 |

| 2″ | 160 | 4499 | 3880 | 3486 | 3205 | 2980 | 2840 | 2755 | 2699 | 2671 |

| 3″ | 40 | 1806 | 1558 | 1400 | 1287 | 1196 | 1140 | 1106 | 1084 | 1072 |

| 3″ | 80 | 2553 | 2202 | 1979 | 1819 | 1691 | 1612 | 1564 | 1532 | 1516 |

| 3″ | 160 | 3840 | 3312 | 2976 | 2736 | 2544 | 2424 | 2352 | 2304 | 2280 |

| 4″ | 40 | 1531 | 1321 | 1187 | 1091 | 1014 | 967 | 938 | 919 | 909 |

| 4″ | 80 | 2213 | 1909 | 1715 | 1577 | 1466 | 1397 | 1355 | 1328 | 1314 |

| 4″ | 160 | 3601 | 3106 | 2791 | 2566 | 2386 | 2273 | 2206 | 2161 | 2138 |

| 5″ | 40 | 1342 | 1158 | 1040 | 956 | 889 | 847 | 822 | 805 | 797 |

| 5″ | 80 | 1981 | 1709 | 1535 | 1411 | 1312 | 1250 | 1213 | 1189 | 1176 |

| 5″ | 160 | 3414 | 2945 | 2646 | 2433 | 2262 | 2155 | 2091 | 2049 | 2027 |

| 6″ | 40 | 1219 | 1052 | 945 | 869 | 808 | 770 | 747 | 732 | 724 |

| 6″ | 80 | 1913 | 1650 | 1483 | 1363 | 1267 | 1208 | 1172 | 1148 | 1136 |

| 6″ | 160 | 3289 | 2836 | 2549 | 2343 | 2179 | 2076 | 2014 | 1973 | 1953 |

| 8″ | 40 | 1073 | 926 | 832 | 765 | 711 | 678 | 657 | 644 | 637 |

| 8″ | 80 | 1692 | 1459 | 1311 | 1205 | 1121 | 1068 | 1036 | 1015 | 1005 |

| 8″ | 160 | 3175 | 2738 | 2460 | 2262 | 2103 | 2004 | 1944 | 1905 | 1885 |

| 10″ | 40 | 974 | 840 | 755 | 694 | 945 | 615 | 596 | 584 | 578 |

| 10″ | 80 | 1609 | 1388 | 1247 | 1147 | 1066 | 1016 | 986 | 966 | 956 |

| 10″ | 160 | 3147 | 2714 | 2439 | 2242 | 2085 | 1986 | 1927 | 1880 | 1868 |

Stainless Steel TP321 Seamless Pipes Application

ASTM A312 TP321 Stainless steel seamless pipe are known to deliver exceptional performance and are generally developed for meeting the demands. We offer a broad range of A312 / SA312 Austenitic Stainless Steel 321 Piping through a worldwide network of stock-keeping branches. These Seamless Pipe is use in various industries like :

Roestvrij staal 321 Seamless Pipes uses in Water Supply Systems

Austenitic SS TP321 Seamless Pipes uses in Power Plant

TP321 Steel Seamless Piping uses in Paper & Pulp Industry

SS 321 Seamless Pipes uses in General Purpose Applications

Roestvrij staal 321 Seamless Pipes uses in Fabrication Industry

Austenitic steel 321 Seamless Pipes uses in Food Processing Industry

Stainless Steel TP321 Seamless Pipes uses in Structural Pipe

ASTM A312 Stainless Steel Pipes uses in Oil and Gas Pipeline

ASME SA312 Seamless Piping uses in Chemical Industry

SUS 321 Stainless Steel Seamless Pipes uses in Plumbing

AISI 321 Seamless Stainless Steel Pipes uses in Heating

Leverancier van roestvrijstalen buizen Wenzhou Kaixin China

Leverancier van roestvrijstalen buizen Wenzhou Kaixin China