ASTM A312 TP316L Stainless Steel Seamless Pipe Benefits

Stainless steel pipes are essential in many industries. Among them, TP316L stainless steel pipes stand out for their unique benefits.

These pipes are known for their durability and resistance to corrosion. They are particularly favored in harsh environments.

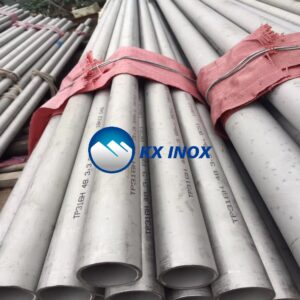

The ASTM A312 TP316L stainless steel seamless pipe is a popular choice. It offers improved weldability and reduced risk of carbide precipitation.

This makes it ideal for high-temperature and corrosive applications.

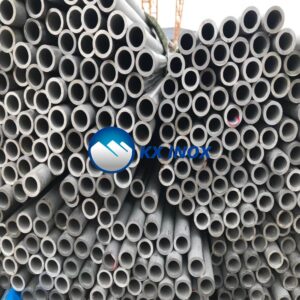

Seamless construction ensures a smooth surface and uniform strength. This reduces the risk of leaks and failures.

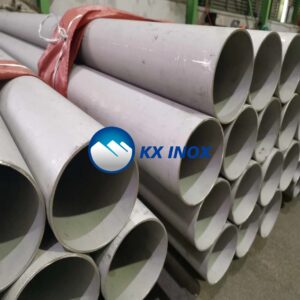

The pipes are versatile, available in various sizes and thicknesses.

Industries like oil and gas, chemical processing, and food and beverage rely on these pipes.

Their long-term cost savings and environmental benefits make them a preferred choice.

What is ASTM A312 TP316L Stainless Steel Seamless Pipe?

The ASTM A312 TP316L stainless steel seamless pipe is a key material in construction and engineering.

It is a low-carbon variation of the 316 stainless steel alloy. This makes it easier to weld and reduces the chance of carbide precipitation during welding.

The specification, ASTM A312, covers seamless and welded stainless steel pipes. These pipes are intended for high-temperature and general corrosive service.

It ensures that pipes meet a standard for durability and strength.

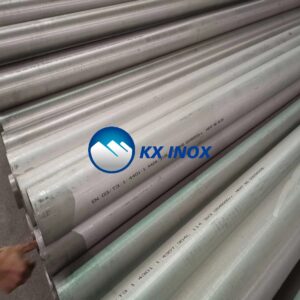

TP316L stainless steel pipes are crafted with a precise seamless construction.

This manufacturing process involves extrusion, resulting in a product with no welds or seams. Stoga, the pipes are strong and can withstand high pressure.

Key features of ASTM A312 TP316L pipes include:

- High corrosion resistance: Ideal for harsh environments.

- Low carbon content: Reduces intergranular corrosion risk.

- Non-magnetic: Beneficial for specific applications.

- Smooth interior surface: Enhances fluid flow and reduces pressure loss.

Key Properties of TP316L Stainless Steel Pipes

TP316L stainless steel pipes are renowned for their superior properties. These pipes excel in various demanding environments due to their robust composition.

The addition of molybdenum enhances resistance to pitting and crevice corrosion, making them apt for marine and chemical settings.

The low carbon content in TP316L brings additional benefits. It minimizes carbide precipitation during welding.

This ensures the material remains strong and less prone to corrosion at the welded points, extending the pipe’s lifespan.

Naduti, TP316L pipes are non-magnetic when in the annealed condition.

This characteristic is crucial for applications needing minimal magnetic interference.

Consequently, these pipes are often used in sensitive electronic environments.

Notably, these pipes exhibit remarkable tensile strength and toughness. These attributes are critical for withstanding high-pressure conditions.

In turn, they support a range of industrial applications where reliability is a priority.

Key properties include:

High corrosion resistance

Enhanced weldability

Non-magnetic nature

High tensile strength

Low carbon content

These properties collectively make TP316L pipes a reliable choice in diverse industry sectors.

Advantages of Seamless Construction

Seamless construction is a significant advantage in the manufacturing of TP316L stainless steel pipes.

This method involves extruding the steel to form a pipe without any welded seams.

The absence of welded joints ensures a uniform structure with enhanced integrity.

Seamless steel pipes boast numerous benefits over their welded counterparts.

Notably, they have greater pressure handling capabilities, ideal for high-pressure applications.

This feature is crucial in industries like oil and gas, where reliability is non-negotiable.

Seamless pipes offer a smooth interior surface, which reduces friction and pressure drops in fluid systems.

Dodatno, the unbroken surface ensures an even strength distribution, minimizing the risk of leaks and failures. Their seamless nature results in:

Improved pressure handling

Smooth, continuous interior

Enhanced strength and reliability

These advantages underscore the preference for seamless pipes in critical applications.

Corrosion Resistance and Durability

TP316L stainless steel pipes are renowned for their exceptional corrosion resistance.

This makes them ideal for environments where exposure to corrosive elements is inevitable.

The inclusion of molybdenum enhances resistance to pitting and crevice corrosion.

Durability is another hallmark of TP316L pipes. Their robust construction ensures long service life even in harsh conditions.

Industries such as chemical processing and marine applications rely on these pipes for their resilience against chloride stress corrosion cracking.

These pipes are designed to withstand a range of temperatures and pressures.

Their ability to endure acidic and alkaline solutions without degradation highlights their versatility. Key attributes include:

Resistance to pitting and crevice corrosion

Chloride stress corrosion cracking resistance

Extended lifespan in harsh environments

TP316L stainless steel pipes represent a reliable choice for ensuring long-lasting performance in challenging conditions.

Applications Across Industries

TP316L stainless steel pipes find widespread use in numerous industries thanks to their unparalleled properties.

In the chemical sector, they are utilized for transporting aggressive chemicals. Their resistance to corrosion ensures that the transported substances remain untainted.

The oil and gas industry also favors these pipes for their ability to withstand harsh conditions.

Their use in offshore platforms is well-documented, particularly due to their durability in marine environments.

This application underscores the pipes’ strength and reliability under pressure.

In food and beverage processing, TP316L pipes are prized for their hygienic qualities.

They offer a smooth, easy-to-clean surface that upholds strict health standards.

Key uses include:

- Kemijska obrada

- Oil and gas

- Food and beverage

These examples illustrate the adaptability of TP316L pipes to various demanding requirements, emphasizing their essential role across diverse sectors.

Cost Efficiency and Long-Term Value

TP316L stainless steel pipes are an investment in durability and efficiency. Their robust construction reduces maintenance needs, saving both time and money.

Over time, this translates into significant cost savings for businesses.

The long service life of these pipes further enhances their value. They resist corrosion and extreme temperatures, minimizing the need for frequent replacements.

This longevity ensures that initial investments yield lasting benefits. Key cost-efficiency factors include:

- Low maintenance needs

- Reduced replacement frequency

- Extended service life

These advantages make TP316L stainless steel pipes a pragmatic choice for projects requiring reliability and economic efficiency in the long run.

Environmental and Safety Benefits

TP316L stainless steel pipes are not only durable but also eco-friendly. They are fully recyclable, supporting sustainable practices.

This recyclability reduces environmental impact over time, contributing to greener projects.

Safety is another critical benefit. These pipes withstand harsh conditions without degrading, ensuring reliable performance.

Their resistance to chemical reactions prevents hazardous leaks. Key safety features include:

- Non-toxic and inert nature

- Chemical and temperature resistance

- Prevention of leaks

These attributes make TP316L pipes an excellent choice for industries prioritizing safety and environmental responsibility.

Conclusion

In conclusion, TP316L stainless steel pipes offer a range of benefits unmatched by other materials.

Their superior corrosion resistance and seamless construction ensure long-lasting performance.

Industries across the board appreciate these pipes for their durability and cost-effectiveness.

From chemical processing to architecture, TP316L pipes deliver reliable solutions.

Investing in these pipes means choosing quality, safety, and sustainability for any application.

Wenzhou Kaixin Kaixin Metal Co., Ltd

Wenzhou Kaixin Kaixin Metal Co., Ltd