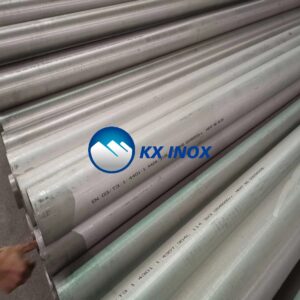

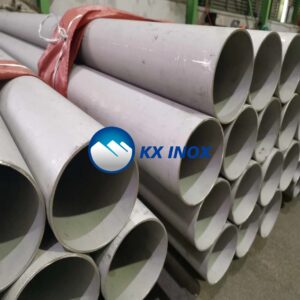

Top Quality ASTM A213 TP321 Stainless Steel Pipes from China

ASTM A213 TP321 stainless steel seamless pipes are essential in many industries. They offer strength and durability for demanding applications.

These pipes are known for their excellent resistance to corrosion and high temperatures. This makes them ideal for use in harsh environments.

Manufactured without welds, seamless pipes provide enhanced reliability and safety. They are crucial in industries where performance cannot be compromised.

China is a leading producer of these high-quality pipes. It offers competitive pricing and meets international standards.

This article explores the specifications, benefits, and applications of ASTM A213 TP321 pipes. Discover why they are a preferred choice worldwide.

Overview of ASTM A213 TP321 Stainless Steel Seamless Pipe

ASTM A213 TP321 stainless steel seamless pipes are specifically designed for high-temperature conditions.

They are used in boiler, Pregrijač, and heat-exchanger tubes across various sectors.

The unique composition of TP321 steel includes titanium. This element stabilizes the material, preventing carbide precipitation, which enhances its resistance to corrosion.

Seamless pipes, such as those under ASTM A213, are manufactured without any welds.

This results in a product that possesses superior strength and corrosion resistance.

Their applications are diverse, spanning critical industries, uključujući petrokemijski, kemijski, and oil and gas. Companies prefer these pipes for the following reasons:

- High temperature and pressure resistance

- Enhanced mechanical properties

- No welds, reducing weaknesses

- Conformance to strict international standards

u sažetku, ASTM A213 TP321 seamless pipes offer unmatched performance in tough environments.

They combine robustness with longevity, providing an optimal solution for various engineering needs.

Chemical Composition and Mechanical Properties

Understanding the composition and properties of TP321 stainless steel is crucial. This alloy’s unique formulation includes specific elements for enhanced performance.

A thorough grasp of these factors is vital for selecting the right pipe for industrial applications.

The mechanical properties of ASTM A213 TP321 offer distinct advantages. They provide the pipe with high durability and resistance to corrosive environments.

These features make it suitable for demanding applications in various industries.

The blend of chemical elements and mechanical characteristics results in a pipe that excels in high-temperature conditions. When choosing piping systems, these benefits are paramount.

Engineers often rely on TP321 seamless pipes to ensure safety and efficiency in their projects.

Chemical Composition of TP321 Stainless Steel

The chemical makeup of TP321 significantly impacts its performance and durability. Each element plays a part in its capabilities.

Some key components include:

- Carbon: Ensures hardness and strength

- Chromium: Enhances corrosion resistance

- nikal: Adds toughness and stability

- Titanij: Prevents carbide precipitation

- Manganese: Improves strength and hardness

This precise composition makes TP321 a strong choice for industrial piping needs.

Mechanical Properties of ASTM A213 TP321 Pipe

TP321 pipes possess notable mechanical traits. These characteristics help withstanding harsh conditions and heavy wear.

Some crucial properties include:

- Snaga popuštanja: 205 MPa minimum

- Zatečna čvrstoća: 515 MPa minimum

- Produženje: 35% minimum

- Tvrdoća: Maksimum 217 HB

These qualities contribute to the pipe’s ability to perform efficiently in pressure and heat environments.

Manufacturing Process of Seamless Stainless Steel Pipe

The production of seamless stainless steel pipe is intricate and precise. This process involves several key stages, each contributing to the pipe’s strength and durability.

By eliminating welds, seamless pipes can withstand high pressure and temperature.

Initially, a solid billet of steel is subjected to extreme heat. This heating softens the billet, making it easier to shape and handle.

The softened billet is then pierced with a mandrel to create a hollow tube, removing any seams or joints.

Following piercing, the tube is stretched and rolled to achieve the desired thickness and diameter.

The hot rolling process aligns the steel’s grain structure, enhancing both its toughness and ductility.

After rolling, the pipe undergoes controlled cooling to stabilize its mechanical properties.

The final phase involves finishing, where the pipe is cut to size and its surface is treated. Treatment options include polishing, kiseli, and annealing.

These finishes not only improve aesthetics but also boost corrosion resistance, making the pipe suitable for a wide range of applications.

Key Features and Benefits of ASTM A213 TP321 Seamless Pipe

ASTM A213 TP321 seamless pipe offers a range of exceptional features that meet rigorous industrial demands. Its titanium stabilization provides superior resistance to intergranular corrosion.

This feature is crucial for maintaining integrity in fluctuating temperatures.

The seamless construction of these pipes enhances their strength and reliability. Without welded seams, they are less susceptible to corrosion and leakage.

This makes them ideal for critical applications in harsh environments.

Dodatno, TP321 stainless steel exhibits remarkable thermal resistance. The pipes can withstand high temperatures without compromising their structural integrity.

This trait benefits industries such as chemical, petrochemical, and oil and gas.

The benefits of ASTM A213 TP321 pipes include:

- Excellent corrosion resistance

- High tensile strength and durability

- Versatility in various applications

- Compatibility with different fittings and flanges

Moreover, the pipes are available in various surface finishes and sizes, catering to diverse project needs.

This flexibility enhances their appeal across multiple industries, ensuring they deliver performance and cost-effectiveness.

Applications of ASTM A213 TP321 Stainless Steel Seamless Pipe

ASTM A213 TP321 stainless steel seamless pipes are integral in many industrial sectors. Their robustness and corrosion resistance make them suitable for demanding applications.

They perform exceptionally well in high-temperature environments.

These pipes are a staple in the chemical and petrochemical industries. Their ability to withstand corrosive substances ensures long-term reliability.

For oil and gas applications, their strength and leak-free construction are crucial.

The food processing industry also benefits from these pipes due to their hygienic properties. They maintain purity without reacting with food products.

This capability is essential for maintaining quality and safety in food production.

Key applications of ASTM A213 TP321 seamless pipes include:

- Heat exchangers and condensers

- Boilers and superheaters

- Marine and shipbuilding industries

- Power generation and steam transport

Their versatility extends to construction, farmaceutski proizvodi, and automotive sectors.

In each field, these pipes offer unique advantages, ensuring they remain a preferred choice for engineers and industry professionals.

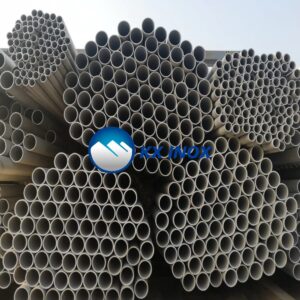

Size Range, Dimenzije, and Surface Finishes

ASTM A213 TP321 stainless steel seamless pipes come in diverse sizes and dimensions. This variety ensures they meet the specific needs of various projects.

Their availability in different diameters and thicknesses adds flexibility for engineers and designers.

These pipes are adaptable to both metric and imperial systems. This versatility allows for global compatibility in piping projects.

Custom lengths and diameters can be ordered, catering to bespoke industrial requirements and enhancing project efficiency.

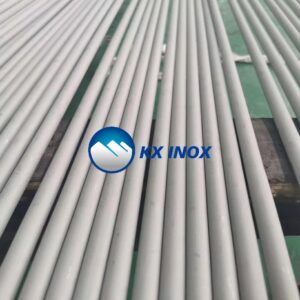

Surface finishes for these pipes vary. Options include polished, ukiseljen, and annealed finishes. These are selected based on intended use:

- Polished for aesthetic applications.

- Pickled for enhanced corrosion resistance.

- Annealed for improved ductility.

Each finish enhances the pipe’s properties to suit specific environments and operational demands. Whether for aesthetic appeal or functional performance, ASTM A213 TP321 pipes deliver reliable results.

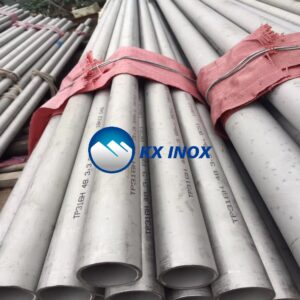

Quality Standards, Testing, and Certifications

ASTM A213 TP321 stainless steel seamless pipes adhere to strict quality standards. These standards ensure pipes meet international performance and safety criteria.

Compliance is crucial for maintaining high reliability in industrial applications.

Testing is an essential part of the manufacturing process.

Each pipe undergoes rigorous assessments, including hydrostatic and non-destructive tests.

These tests confirm the pipes’ integrity and suitability for demanding environments.

Certifications enhance the pipes’ credibility and marketability.

They often include ISO, CE, and PED certifications, verifying quality and compliance.

These certifications assure stakeholders of the pipes’ adherence to global industry standards:

- ISO for quality management.

- CE for European market conformity.

- PED for pressure equipment standards.

Stringent standards and comprehensive testing make these pipes a trusted choice worldwide.

Why Source ASTM A213 TP321 Seamless Pipe from China?

China is a leading manufacturer of ASTM A213 TP321 stainless steel seamless pipes. Chinese manufacturers offer competitive pricing without compromising quality.

This balance is attractive to buyers worldwide.

Production capabilities in China are extensive.

Factories are equipped with advanced technology, enhancing efficiency and precision.

This capability results in reliable, high-quality products.

Moreover, manufacturers offer comprehensive services.

These include custom specifications, thorough testing, and timely delivery.

Choosing a supplier from China offers several advantages:

- Competitive pricing

- Advanced manufacturing processes

- High-quality assurance

- Customization and flexibility

- Efficient logistics and distribution

Sourcing from China provides access to a robust supply chain with global reach.

How to Select the Right ASTM A213 TP321 Pipe for Your Project

Choosing the right ASTM A213 TP321 seamless pipe requires careful consideration of your project’s unique needs.

Factors such as temperature, pressure, and fluid type play crucial roles.

Understanding the environment where the pipe will be used is vital.

Pipes must withstand specific conditions, including corrosion potential and temperature variations.

Consulting with experts can help identify the best options. They can guide you in selecting the right diameter, debljina, and finish.

Consider the following elements:

- Application specifics (e.g., kemijski, nafta i plin, construction)

- Required pipe size and thickness

- Environmental factors (e.g., temperature, otpor korozije)

- Compatibility with existing systems

A well-chosen pipe maximizes efficiency and ensures long-term reliability in demanding applications.

Tailoring your selection to project specifications ensures optimal performance.

Frequently Asked Questions (FAQ)

What is ASTM A213 TP321 stainless steel seamless pipe?

ASTM A213 TP321 is a specification for seamless stainless steel pipes used in high-temperature environments.

It provides excellent resistance to corrosion and is stabilized with titanium.

Where are these pipes commonly used?

These pipes are utilized in industries like chemical, petrochemical, and oil and gas. They are ideal for heat exchangers and boilers.

How does TP321 stainless steel benefit industrial applications?

TP321 offers superior corrosion resistance and mechanical strength. It supports high-pressure and temperature systems effectively.

Why choose seamless stainless pipes?

Seamless pipes have no welds, reducing leakage risks and enhancing strength. They are perfect for critical applications.

- What is the main advantage of a seamless pipe?

- Do TP321 pipes support welding?

- Can these pipes be used in marine environments?

- Are there specific sizes available for TP321 pipes?

- What standards do these pipes comply with?

Seamless design and high resistance make these pipes a top choice for various industrial needs. Their versatility and durability are unmatched.

Conclusion

ASTM A213 TP321 stainless steel seamless pipes offer a reliable solution for demanding industrial applications.

Their excellent corrosion resistance and durability make them ideal for high-temperature environments.

Sourced primarily from China, these pipes meet international quality standards, providing a cost-effective option for global projects.

They ensure safety and performance, making them an essential component in various industries.

By choosing TP321 seamless pipes, you gain a blend of quality, efficiency, and versatility critical for modern infrastructure needs.

Wenzhou Kaixin Kaixin Metal Co., Ltd

Wenzhou Kaixin Kaixin Metal Co., Ltd