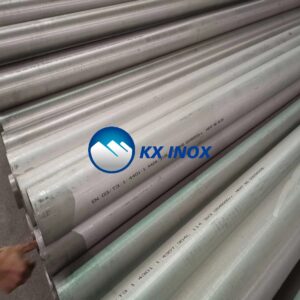

ASTM A213 TP316L Stainless steel seamless pipe specification

The ASTM A213 TP316L seamless pipe is a vital component in many industrial applications.

Known for its high corrosion resistance, this stainless steel pipe is a preferred choice in harsh environments.

Its seamless construction ensures uniform strength, making it ideal for high-pressure and high-temperature uses.

Engineers and procurement specialists often select TP316L for its excellent mechanical properties and durability.

The low-carbon content enhances weldability, reducing the risk of carbide precipitation.

This makes it suitable for industries like petrochemical, nafta i plin, and food processing.

The pipe’s versatility extends to marine and architectural applications, thanks to its resistance to saltwater and aesthetic appeal.

With a range of sizes and thicknesses, it meets diverse industrial needs.

What is ASTM A213 TP316L Seamless Pipe?

The ASTM A213 TP316L seamless pipe is a specification for stainless steel pipes.

It describes pipes that are seamless and made from alloy 316L. This alloy is a low-carbon version of 316, which enhances its properties for specific applications.

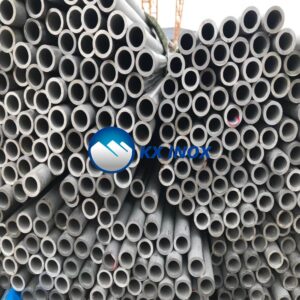

Seamless pipes have no welded seams, making them stronger and more reliable under pressure.

This is crucial in environments where safety and longevity are prioritized.

The TP316L variant contains additional molybdenum, improving its resistance to pitting and crevice corrosion.

Key aspects of ASTM A213 TP316L seamless pipes include:

- High corrosion resistance, especially in chloride environments.

- Excellent weldability due to low carbon content.

- Versatility in sizes and thicknesses for various applications.

These qualities make TP316L a trusted material in many industrial sectors.

Chemical Composition and Mechanical Properties

The chemical composition of ASTM A213 TP316L plays a vital role in its performance. It includes chromium, nickel, and molybdenum, which contribute to its superior corrosion resistance.

The presence of molybdenum enhances its resistance against chlorides and other aggressive environments.

Key elements and their typical compositions are:

- Chromium: 16.0-18.0%

- nikal: 10.0-14.0%

- Molybdenum: 2.0-3.0%

- Carbon: maximum 0.03%

These elements work together to provide a robust material suitable for demanding conditions.

In terms of mechanical properties, TP316L exhibits impressive strength and ductility.

Its tensile strength ensures structural stability, while the low carbon content improves weldability.

The mechanical characteristics are critical for many industrial applications. They include:

- Zatečna čvrstoća: minimum 485 MPA

- Snaga popuštanja: minimum 170 MPA

- Produženje: minimum 35%

These properties make TP316L a reliable choice for high-pressure and high-temperature applications. Its durability and resistance to thermal expansion and contraction are beneficial. This makes the pipe apt for rigorous environments and long-term use.

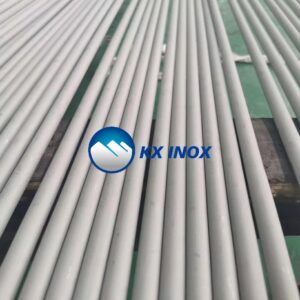

Key Features and Benefits of TP316L Seamless Stainless Pipe

ASTM A213 TP316L seamless pipe is famed for its remarkable attributes. One of its key features is high corrosion resistance, especially in chlorinated environments.

This makes it extremely versatile for various industrial applications.

The seamless construction provides a uniform structure. This eliminates concerns about seam failure, resulting in a strong and reliable product.

Such consistency ensures longevity and durability under different stress conditions.

Here are some benefits of TP316L seamless stainless pipe:

- Improved weldability due to low carbon content

- Superior resistance to pitting and crevice corrosion

- High-temperature and high-pressure suitability

Its ability to withstand harsh conditions while maintaining structural integrity is impressive.

This makes it a preferred choice in demanding sectors such as petrochemical and marine industries. These strengths allow for effective and efficient operation, reducing maintenance and downtime.

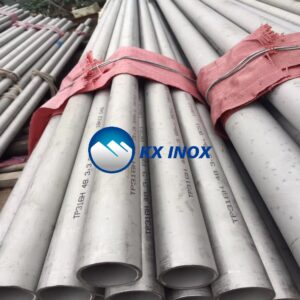

Manufacturing Process of ASTM A213 TP316L Seamless Pipe

The production of ASTM A213 TP316L seamless pipe involves a series of meticulous steps. It begins with heating solid steel billets to high temperatures.

This process softens the material, preparing it for further shaping.

Once heated, the billets are shaped into hollow tubes. This is achieved through a piercing process, which creates the initial seamless structure. Subsequent steps refine the dimensions and properties of the pipe.

Key stages in the manufacturing process include:

- Heating and piercing of solid billets

- Rolling and sizing to meet specific dimensions

- Heat treatment to enhance mechanical properties

These stages ensure that the final product meets precise standards. Each seamless pipe boasts uniform quality and excellent mechanical properties due to this comprehensive process.

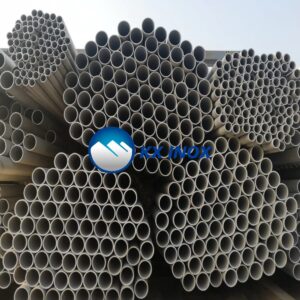

Standard Sizes, Dimenzije, and Tolerances

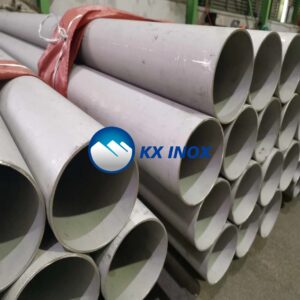

The ASTM A213 TP316L seamless pipe comes in diverse sizes to cater to various needs. Standard diameters range from small to large bore, offering flexibility in applications.

This variety ensures suitability for different industrial tasks.

These pipes adhere to strict dimensional standards and tolerances. Precise manufacturing processes ensure that each pipe meets exact specifications, maintaining uniformity across batches.

Key dimensions and tolerances include:

- Outer diameter range: From small (6mm) to large (600mm) veličine

- Wall thickness: From thin to thick walls, depending on requirements

- Length options: Customizable to meet project needs

These standards guarantee compatibility with global applications. Consistent dimensions make integration into existing systems straightforward, enhancing efficiency.

Applications of ASTM A213 TP316L Stainless Steel Pipe

ASTM A213 TP316L seamless pipes serve various demanding industries. They are favored for their superior corrosion resistance and durability.

This makes them ideal for harsh environments where other materials may fail.

Typical applications include sectors where high strength and resilience are critical. The petrochemical industry, for instance, relies on these pipes for transporting chemicals safely.

Food processing also benefits from their hygienic properties and ease of cleaning.

Key applications include:

- Petrochemical industry for chemical transportation

- Food and beverage production

- Pharmaceutical processing

- Heat exchangers and boiler systems

- Marine applications for saltwater resistance

These versatile pipes are invaluable across a broad range of industrial uses. Their adaptability and consistent performance ensure they meet the specific needs of each field effectively.

Comparison with Other Stainless Steel Pipe Grades

ASTM A213 TP316L stands out among other stainless steel pipe grades. Its low carbon content offers improved weldability without sacrificing strength.

This feature makes it preferable for complex fabrication projects.

In contrast, some stainless steel grades, like 304, lack the same level of corrosion resistance. TP316L’s enhanced performance in chloride-rich environments gives it a distinct advantage.

Key differences include:

- Improved weldability over standard 316 grade

- Better corrosion resistance than grade 304

- Suitable for more aggressive chemical environments

This combination of features makes TP316L an excellent choice for demanding applications. Its unique properties ensure reliability and longevity where other grades may fail.

Quality Standards and Certifications

ASTM A213 TP316L seamless pipes adhere to stringent quality standards. These standards ensure pipes perform reliably in various applications.

These standards are globally recognized and provide assurance of the product’s quality and durability.

Key certifications include:

- Compliance with ASTM A213 specifications

- Adherence to ISO quality management standards

- Certification for safe use in different industries

These certifications reflect the high-quality manufacturing processes involved.

They ensure that the pipes meet international safety and quality benchmarks, thus providing confidence to users in diverse sectors.

Conclusion

ASTM A213 TP316L seamless pipes stand out for their excellent performance in various environments.

Their resistance to corrosion and durability make them an ideal choice across industries.

These pipes meet rigorous quality standards, ensuring safety and reliability.

Whether used in high temperatures or harsh conditions, TP316L seamless pipes deliver consistent results, making them indispensable in numerous applications.

Wenzhou Kaixin Kaixin Metal Co., Ltd

Wenzhou Kaixin Kaixin Metal Co., Ltd