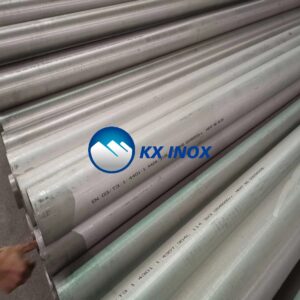

ASTM A213 TP304L stainless steel seamless pipes are essential in many industries.

They offer strength, durability, and resistance to corrosion.

These pipes are crucial for high-pressure and high-temperature applications.

China is a leading producer of these seamless steel pipes. The country provides high-quality products at competitive prices.

This makes China a preferred choice for many global buyers.

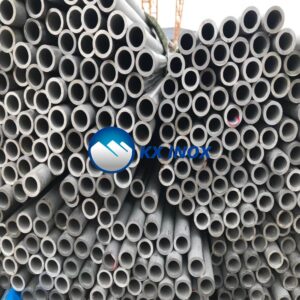

The seamless design of these pipes ensures uniformity and reliability. They are ideal for critical applications where safety is paramount.

Their versatility makes them suitable for various industrial uses.

Understanding the specifications and benefits of ASTM A213 TP304L pipes is vital.

This guide will explore their features, applications, and why China is a top supplier.

Overview of TP304L Stainless Steel Seamless Pipe

ASTM A213 TP304L is a specification for seamless ferritic and austenitic steel tubes. These tubes are used in boilers, superheaters, i izmjenjivači topline.

The pipes are known for their exceptional performance in various settings.

The TP304L grade refers to a low-carbon version of 304 nehrđajući čelik. This grade has enhanced weldability and reduces the risk of carbide precipitation.

As a result, it provides greater resistance to corrosive environments.

Seamless steel pipes are designed to withstand high pressure and temperature. The absence of seams ensures uniform strength and minimizes the risk of leaks.

This reliability is crucial in industries like petrochemical and power generation.

Some key features of ASTM A213 TP304L include:

- Excellent corrosion resistance

- High-temperature strength

- Durability and reliability

China has become a prominent producer of ASTM A213 TP304L pipes.

The country’s modern manufacturing techniques and quality control measures ensure top-notch products.

As a result, Chinese manufacturers meet both domestic and international demands effectively.

Chemical Composition and Mechanical Properties

The chemical composition of ASTM A213 TP304L stainless steel is carefully balanced. This ensures both strength and corrosion resistance.

The low carbon content is a key feature.

Key Chemical Elements in TP304L:

- Carbon: Maksimum 0.03%

- Chromium: 18.0-20.0%

- nikal: 8.0-12.0%

- Manganese: Maksimum 2.0%

- Silicon: Maksimum 0.75%

- Phosphorus: Maksimum 0.045%

- Sulfur: Maksimum 0.03%

These elements contribute to the steel’s durability and adaptability.

The chromium and nickel give TP304L its anti-corrosive properties, making it ideal for harsh environments.

Mechanically, TP304L stainless steel excels in several areas. It offers a perfect mix of strength and ductility.

The metal is also tough, even at high temperatures.

Mechanical Properties of TP304L:

- Zatečna čvrstoća: Min 485 MPA

- Snaga popuštanja: Min 170 MPA

- Produženje: Min 35%

- Tvrdoća (Brinell): Maksimum 201 HB

These traits make TP304L suitable for demanding applications. Industries often choose it for its reliable performance and long lifespan.

This versatility underscores its widespread use across sectors.

Manufacturing Process of Seamless Steel Pipe

The manufacturing process of seamless steel pipes is distinct and sophisticated. It involves no welding, ensuring the pipe’s integrity and strength.

This feature makes seamless pipes ideal for high-pressure applications.

Seamless pipes are made through various methods. The most common methods include rotary piercing and extrusion.

Both techniques start with a solid steel billet, which is heated to a high temperature.

Key Steps in the Manufacturing Process:

- Rotary Piercing: A billet is elongated and pierced to form a hollow shell.

- Extrusion: The hollow shell is stretched to form a seamless pipe.

- Završnica: The pipe is then sized, rolled, and sometimes heat-treated.

During these processes, precision is crucial. The absence of welds means seamless pipes are free from potential weak spots.

This results in a more uniform structure compared to welded pipes. Due to these qualities, seamless pipes are highly reliable in critical applications.

Key Features and Benefits of TP304L Stainless Steel Pipe

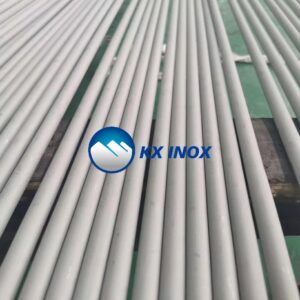

TP304L stainless steel pipes offer a range of compelling features. One of the most notable is their excellent corrosion resistance.

This quality makes them suitable for diverse environments, from marine to chemical industries.

These pipes boast high-temperature strength. They perform well under both high-temperature and cryogenic conditions.

This versatility enhances their appeal across various sectors.

Advantages of TP304L Stainless Steel Pipes:

- Improved Weldability: Low carbon reduces carbide precipitation during welding.

- Durability: High resistance to corrosion ensures long service life.

- Mechanical Strength: Offers a balance of strength and ductility.

- Reduced Maintenance: Easy to clean and maintain, cutting costs.

- Non-Magnetic: Useful in applications requiring this property.

TP304L pipes are also preferred for their seamless construction. This ensures a uniform surface, minimizing leak risk.

Dodatno, their aesthetic finish makes them viable for visible architectural applications.

With these benefits, TP304L stainless steel pipes remain a preferred choice in many industries, offering reliability and efficiency.

Applications of TP304L Stainless Steel Seamless Pipe

ASTM A213 TP304L stainless steel seamless pipes are critical in many industries. Their versatility is thanks to their unique features.

In petrochemical and oil and gas sectors, they handle high pressure and corrosive environments. Their durability reduces failure risks significantly.

Common Applications Include:

- Heat Exchangers: Used due to excellent thermal conductivity.

- Chemical Processing Equipment: High corrosion resistance suits harsh chemicals.

- Power Generation: Withstands high-temperature conditions reliably.

- Food and Beverage Industry: Sanitary properties make them ideal here.

- Water Treatment Plants: Resistance to chemicals used in water processing.

In the marine industry, these pipes resist saltwater corrosion. This quality ensures long-term performance for maritime structures. Dodatno, their sanitary nature benefits the pharmaceutical industry.

TP304L pipes are also prevalent in the construction of gas pipelines. Their robust strength ensures safe transport over vast distances.

Similarly, renewable energy systems utilize them for their efficiency and reliability.

Sizing, Tolerances, and Surface Finishes

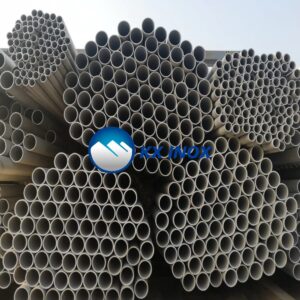

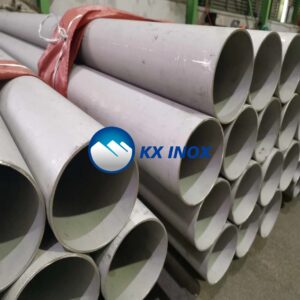

ASTM A213 TP304L stainless steel seamless pipes come in a range of sizes to meet diverse industry needs.

These pipes are available in various diameters and wall thicknesses. It ensures compatibility with different system requirements.

Common Sizes and Tolerances:

- Outside Diameters: From 6mm to 1200mm

- Wall Thicknesses: Between 0.5mm and 25mm

- Dužina: Typically up to 12 metara

Precision in manufacturing assures consistent tolerances, enhancing dimensional accuracy.

Strict quality checks ensure these pipes meet international standards.

Surface finishes are tailored to specific applications. Options like polished, ukiseljen, and annealed finishes offer both aesthetic appeal and function.

The right finish can improve corrosion resistance and cleanliness, crucial for hygiene-sensitive industries like food processing. This versatility in finishes ensures the pipes meet various environmental and operational demands.

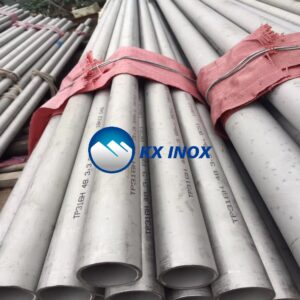

Why Choose Chinese Manufacturers for ASTM A213 TP304L Pipes?

Chinese manufacturers are renowned for producing high-quality ASTM A213 TP304L stainless steel seamless pipes. They offer competitive pricing, making them an economical choice globally.

This cost advantage comes without compromising quality and performance.

Another key benefit of Chinese manufacturers is their advanced technology and production techniques.

These ensure consistent quality and adherence to international standards. Manufacturers in China implement cutting-edge innovations to stay ahead in the industry.

China’s extensive manufacturing infrastructure supports quick production lead times. Efficient logistics and distribution networks ensure timely delivery worldwide.

This reliability makes China a preferred source for many global industries.

Advantages of Chinese Manufacturers:

- Competitive pricing

- Advanced technology

- Efficient logistics

- Consistent quality control

Dodatno, Chinese manufacturers have a wide range of product offerings. From varied sizes to specific surface finishes, they cater to different industrial needs.

This variety ensures that projects of all scales can find suitable solutions, enhancing project success.

Quality Control and International Standards Compliance

Chinese manufacturers of ASTM A213 TP304L stainless steel seamless pipes prioritize quality control.

They implement rigorous testing procedures to ensure every pipe meets specified standards. This commitment to quality ensures consistent performance.

Compliance with international standards is essential for global competitiveness.

Chinese manufacturers adhere to stringent specifications, including ASTM and ISO standards.

Meeting these standards ensures the pipes are suitable for diverse applications.

Key quality measures include non-destructive testing and dimensional checks. These tests confirm the pipes’ integrity and precision.

Moreover, documentation and certification provide additional assurance to customers worldwide.

Quality Assurance Measures:

- Non-destructive testing

- Dimensional accuracy checks

- Adherence to ASTM and ISO standards

Comparison: Seamless vs. Welded Stainless Steel Pipe

Seamless and welded stainless steel pipes offer distinct advantages. Seamless pipes are made without joints, ensuring uniform strength.

They are ideal for high-pressure and high-temperature applications due to their integrity.

Conversely, welded pipes are manufactured by welding a seam, making them cost-effective.

They are suitable for less demanding environments and applications where high pressure is not a concern.

Key Differences:

- Strength: Seamless pipes offer higher strength.

- Cost: Welded pipes are generally more economical.

- Pressure Handling: Seamless pipes excel under high-pressure conditions.

Choosing between the two depends on your specific application needs and budget constraints.

How to Source ASTM A213 TP304L Stainless Steel Seamless Pipe in China

Finding the right supplier is crucial for sourcing ASTM A213 TP304L stainless steel seamless pipes in China.

Prvi, identify reputable manufacturers with proven track records. Consider their experience and expertise in producing high-quality pipes.

Sljedeći, verify the supplier’s compliance with international standards and certifications. This ensures the pipes meet your requirements and offer reliable performance.

Engage with suppliers who have comprehensive quality control measures.

Key Steps to Consider:

- Research Manufacturers: Look for top-rated Chinese producers.

- Check Certifications: Ensure compliance with ASTM standards.

- Evaluate Logistics: Confirm their ability to deliver globally.

Finally, consider logistics and delivery capabilities. Ensure the supplier can handle timely shipments to your locati0n.

Conclusion

ASTM A213 TP304L stainless steel seamless pipes are integral to various industries. Their durability and resistance make them ideal for challenging environments.

The seamless design ensures strength and reliability in high-pressure applications.

Choosing a Chinese manufacturer offers competitive advantages, from quality to cost efficiency.

Their expertise and global reach ensure you receive pipes meeting international standards.

For those seeking dependable and adaptable piping solutions, TP304L pipes remain a top choice for diverse applications.

Wenzhou Kaixin Kaixin Metal Co., Ltd

Wenzhou Kaixin Kaixin Metal Co., Ltd