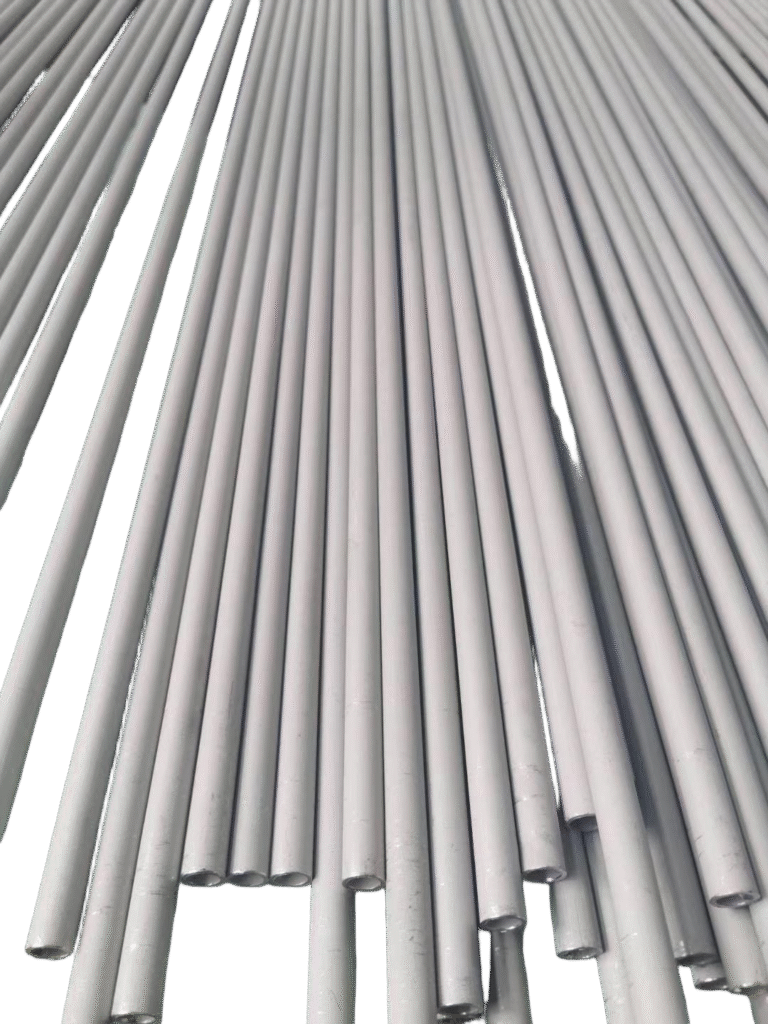

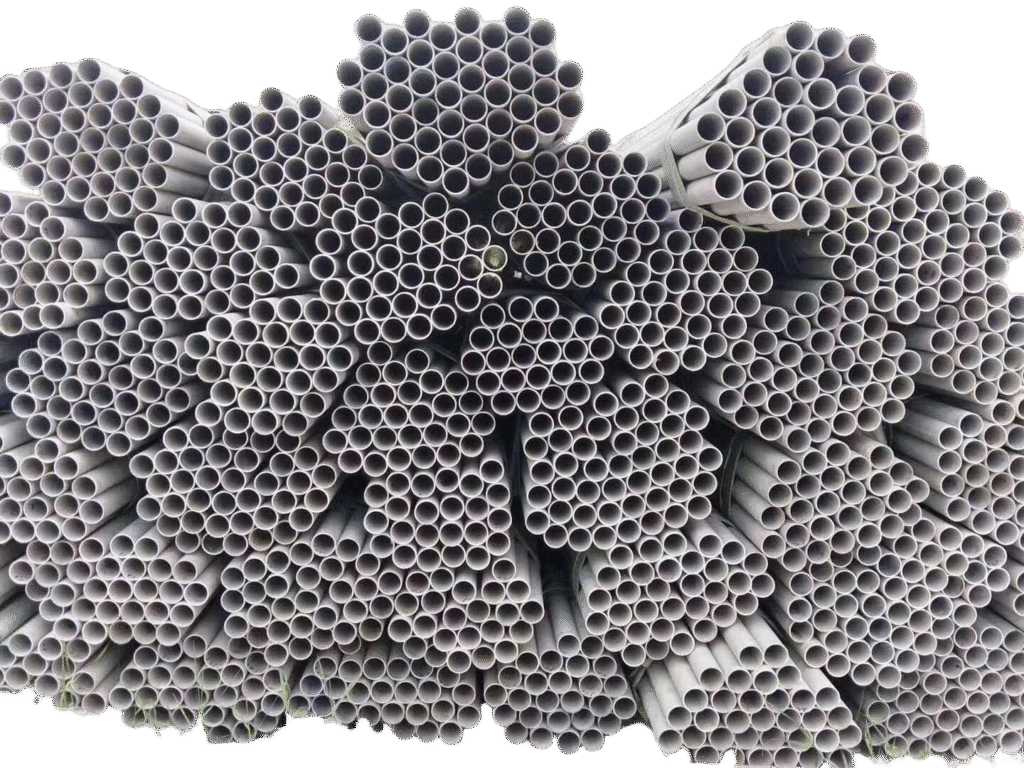

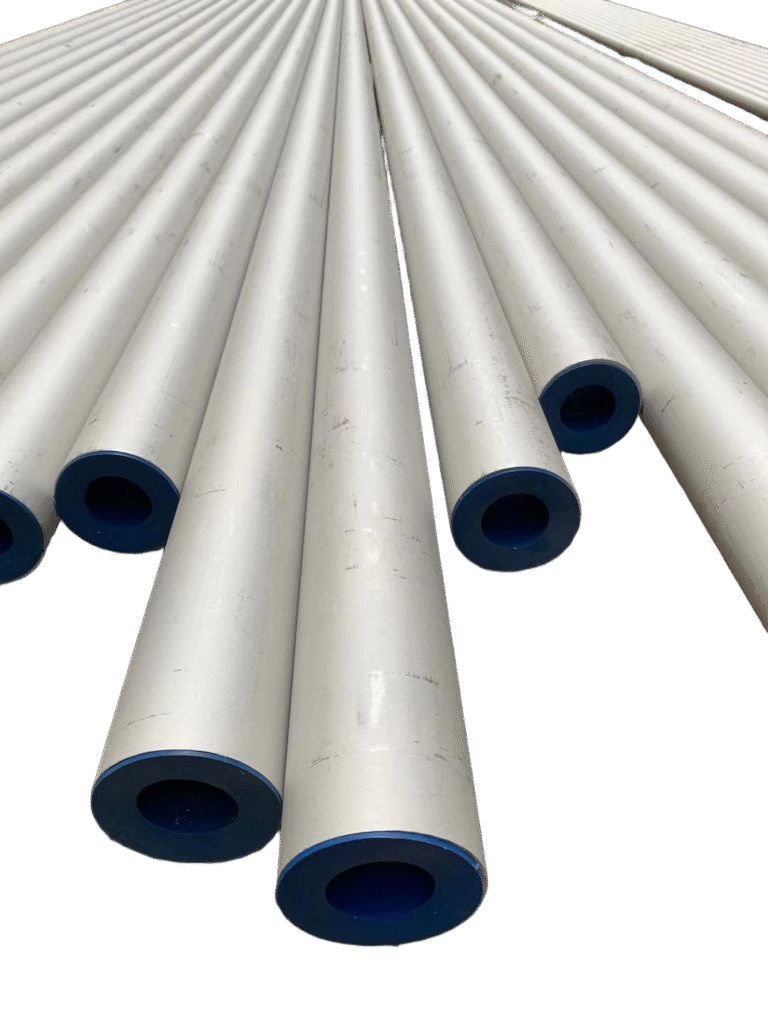

ASTM A312 TP316L Stainless steel seamless pipe

Grade 316L is an austenitic stainless steel that can operate from 450 degrees Celsius to 850 degrees Celsius roughly. The range differs depending on the pressure of a system, the components flowing inside the pipe and the environment outside it. Marine environment is full of chloride ions and the wind and water are salty.

The salty conditions catalyze all forms of corrosions because they act as a medium for electron transfer for oxidation and reduction chemical reactions. The 316L stainless steel pipe has a lower carbon content than the ASTM A312 TP316 which means, there is less intergranular precipitation and local corrosion due to welding. Also, the material has molybdenum in addition to chromium and nickel which is specifically resistant to chloride ion stress corrosion.

316L Stainless Steel Pipe Specification

| Spécification standard | ASTM A312 TP316L ASME SA312 TP316L |

| Taille | ½ to 6 Inch Nominal Bore |

| Schedule Pipe Thickness Range | Calendrier 60, XS, Calendrier 160, Calendrier 120, MST, Calendrier 40, Calendrier 140, Calendrier 20, Calendrier 80, Calendrier 80, XXS, Calendrier 30, Supplier in Mumbai |

| Épaisseur de paroi | 0.1 – 60 mm |

| Longueur | Single Random Length 5 à 7 MeterDouble Random Length 10 – 12 Meter |

| Standard | DEPUIS, IL, ASTM, FR, ASME, AISI, AMS, DANS, GOST |

| Types | Soudé, Sans couture, ACRE, EFW Supplier and Manufacturer |

| Manufacturing Shapes | Round, Box Section, Square, Rectangle |

| Finition de surface | Brillant, Bright, Annealing, Cold Finish, Pickling |

| Technique | Cold Rolled Hot Rolled |

| Manufacturing Technology | Hot Cold Formed |

316L SS Seamless Pipe Equivalent Material

| STANDARD | WERKSTOFF NR. | NOUS | IL | BS | GOST | AFNOR | DANS |

| SS 316L | 1.4404 / 1.4435 | S31603 | SUS 316L | 316S11 / 316S13 | 03Ch17N14M3 / 03Ch17N14M2 | Z3CND17-11-02 / Z3CND18-14-03 | X2CrNiMo17-12-2 / X2CrNiMo18-14-3 |

Composition Standard of ASTM A312 TP 316L Pipe

| Grade | C | Mn | Et | P. | S | Cr | Mo | Dans | Fe |

| SS 316L | 0.035 maximum | 2.0 maximum | 1.0 maximum | 0.045 maximum | 0.030 maximum | 16.00 – 18.00 | 2.00 – 3.00 | 10.00 – 14.00 | 68.89 min |

Mechanical Properties of ASTM A312 TP 316L Stainless Steel Seamless Pipe

| Grade | Résistance à la traction(Mpa) | Point de rendement(Mpa) | Élongation(%) |

| 316L | 485 | 170 | 35 |

Physical Properties of ASTM A312 TP 316L Stainless Steel Seamless Pipe

| GRADE | DENSITY (KG/M3) | ELASTIC MODULUS (GPA) | MEAN CO-EFF OF THERMAL EXPANSION (ΜM/M/°C) | THERMAL CONDUCTIVITY (W/M.K) | SPECIFIC HEAT 0-100°C (J/KG.K) | ELEC RESISTIVITY (NΩ.M) | |||

| 0-100°C | 0-315°C | 0-538°C | AT 100°C | AT 500°C | |||||

| 316L/H | 8000 | 193 | 15.9 | 16.2 | 17.5 | 16.3 | 21.5 | 500 | 74 |

ASTM A312 TP316L PIPE SIZE CHART

| NPS | O.D. (dans) | 10 | 160 | 80 | 40 |

| 1/8″ | .405 | .049 | .095 | .068 | |

| 1/4″ | .540 | .065 | .119 | .088 | |

| 3/8″ | .675 | .065 | .126 | .091 | |

| 1/2″ | .840 | .083 | .187 | .147 | .109 |

| 3/4″ | 1.050 | .083 | .218 | .154 | .113 |

| 1″ | 1.315 | .109 | .250 | .179 | .133 |

| 1 1/4″ | 1.660 | .109 | .250 | .191 | .140 |

| 1 1/2″ | 1.900 | .109 | .281 | .200 | .145 |

| 2″ | 2.375 | .109 | .343 | .218 | .154 |

| 2 1/2″ | 2.875 | .120 | .375 | .276 | .203 |

| 3″ | 3.500 | .120 | .437 | .300 | .216 |

| 3 1/2″ | 4.000 | .120 | .318 | .226 | |

| 4″ | 4.500 | .120 | .531 | .337 | .237 |

| 4 1/2″ | 5.000 | ||||

| 5″ | 5.563 | .134 | .625 | .375 | .258 |

| 6″ | 6.625 | .134 | .718 | .432 | .280 |

| 7″ | 7.625 | ||||

| 8″ | 8.625 | .148 | .906 | .500 | .322 |

| 9″ | 9.625 | ||||

| 10″ | 10.750 | .165 | 1.125 | .593 | .365 |

| 11″ | 11.750 | ||||

| 12″ | 12.750 | .180 | 1.312 | .687 | .406 |

| 14″ | 14.000 | .250 | 1.406 | .750 | .437 |

| 16″ | 16.000 | .250 | 1.593 | .843 | .500 |

| 18″ | 18.000 | .250 | 1.781 | .937 | .562 |

ASTM A312 Stainless Steel Pipe Tolerances

| DE | Tolérance | WTH, mm | Longueur, mm |

| 10.3 à 48.3 | +0.40/-0.80 | +/-12.5%t | +6/-0 |

| over 48.3 à 114.3 | +0.80/-0.08 | ||

| over 114.3 à 219.1 | +1.60/-0.80 | ||

| over 219.1 à 457.2 | +2.40/-0.80 | ||

| over 457.2 à 660.4 | +3.20/-0.80 | ||

| over 660.4 à 864 | +4.00/-0.08 | ||

| over 864 à 1219.2 | +4.80/-0.08 |

Wall Thickness tolerance of ASTM A312 TP316L

| NPS | Wall Thickness Tolerance, % |

| 1/8 To 2-1/2 Incl., All T/D Ratios | Sur 20.2 Sous 12.5 |

| Sur 3 To 18 Incl., T/D Up To 5% Incl.. | Sur 22.5 Sous 12.5 |

| Sur 3 To 18, Incl., T/D > 5% | Sur 15.0 Sous 12.5 |

| 20 And Large, Soudé, All T/D Ratios | Sur 17.5 Sous 12.5 |

| 20 And Large, Sans couture, T/D Up To 5% Incl.. | Sur 22.5 Sous 12.5 |

| >20 And Large, Sans couture, T/D > 5% | Sur 15.0 Sous 12.5 |

316l stainless steel pipe pressure rating

| e Size (pouces) | Pipe Schedule | Dehors Diameter (dans) | Mur Épaisseur (dans) | Pressure Rating (psig) | ||||||||

| Temperature (oF) | ||||||||||||

| 100 | 200 | 300 | 400 | 500 | 600 | 650 | 700 | 750 | ||||

| Allowable Stress (psi) | ||||||||||||

| 16700 | 16700 | 16700 | 15500 | 14400 | 13500 | 13200 | 12900 | 12600 | ||||

| 1″ | 40 | 1.315 | 0.133 | 2205 | 2205 | 2205 | 2047 | 1902 | 1783 | 1743 | 1703 | 1664 |

| 80 | 1.315 | 0.179 | 3061 | 3061 | 3061 | 2841 | 2640 | 2475 | 2420 | 2365 | 2310 | |

| 160 | 1.315 | 0.250 | 4493 | 4493 | 4493 | 4170 | 3874 | 3632 | 3552 | 3471 | 3390 | |

| 1 1/2″ | 40 | 1.900 | 0.145 | 1629 | 1629 | 1629 | 1512 | 1404 | 1317 | 1287 | 1258 | 1229 |

| 80 | 1.900 | 0.200 | 2303 | 2303 | 2303 | 2138 | 1986 | 1862 | 1821 | 1779 | 1738 | |

| 160 | 1.900 | 0.281 | 3362 | 3362 | 3362 | 3120 | 2899 | 2717 | 2657 | 2597 | 2536 | |

| 2″ | 40 | 2.375 | 0.154 | 1371 | 1371 | 1371 | 1272 | 1182 | 1108 | 1083 | 1059 | 1034 |

| 80 | 2.375 | 0.218 | 1985 | 1985 | 1985 | 1843 | 1712 | 1605 | 1569 | 1534 | 1498 | |

| 160 | 2.375 | 0.344 | 3283 | 3283 | 3283 | 3047 | 2831 | 2654 | 2595 | 2536 | 2477 | |

| 3″ | 40 | 3.500 | 0.216 | 1301 | 1301 | 1301 | 1208 | 1122 | 1052 | 1028 | 1005 | 982 |

| 80 | 3.500 | 0.300 | 1844 | 1844 | 1844 | 1712 | 1590 | 1491 | 1458 | 1425 | 1391 | |

| 160 | 3.500 | 0.438 | 2787 | 2787 | 2787 | 2587 | 2403 | 2253 | 2203 | 2153 | 2103 | |

| 4″ | 40 | 4.500 | 0.237 | 1102 | 1102 | 1102 | 1023 | 950 | 891 | 871 | 851 | 831 |

| 80 | 4.500 | 0.337 | 1596 | 1596 | 1596 | 1482 | 1377 | 1291 | 1262 | 1233 | 1204 | |

| 160 | 4.500 | 0.531 | 2611 | 2611 | 2611 | 2424 | 2552 | 2111 | 2064 | 2017 | 1970 | |

| 5″ | 40 | 5.563 | 0.258 | 965 | 965 | 965 | 896 | 832 | 780 | 763 | 746 | 728 |

| 80 | 5.563 | 0.375 | 1428 | 1428 | 1428 | 1325 | 1231 | 1154 | 1129 | 1103 | 1077 | |

| 160 | 5.563 | 0.625 | 2474 | 2474 | 2474 | 2296 | 2133 | 2000 | 1955 | 1911 | 1866 | |

| 6″ | 40 | 6.625 | 0.280 | 877 | 877 | 877 | 814 | 756 | 709 | 693 | 677 | 661 |

| 80 | 6.625 | 0.432 | 1379 | 1379 | 1379 | 1280 | 1189 | 1115 | 1090 | 1065 | 1040 | |

| 160 | 6.625 | 0.719 | 2382 | 2382 | 2382 | 2211 | 2054 | 1925 | 1883 | 1840 | 1797 | |

| 8″ | 40 | 8.625 | 0.322 | 771 | 771 | 771 | 716 | 665 | 623 | 610 | 596 | 582 |

| 80 | 8.625 | 0.500 | 1218 | 1218 | 1218 | 1131 | 1050 | 985 | 963 | 941 | 919 | |

| 160 | 8.625 | 0.906 | 2298 | 2298 | 2298 | 2133 | 1982 | 1858 | 1817 | 1775 | 1734 | |

| 10″ | 40 | 10.750 | 0.365 | 699 | 699 | 699 | 649 | 603 | 565 | 553 | 540 | 528 |

| 80 | 10.750 | 0.594 | 1159 | 1159 | 1159 | 1075 | 999 | 937 | 916 | 895 | 874 | |

| 160 | 10.750 | 1.125 | 2289 | 2289 | 2289 | 2124 | 1974 | 1850 | 1809 | 1768 | 1727 | |

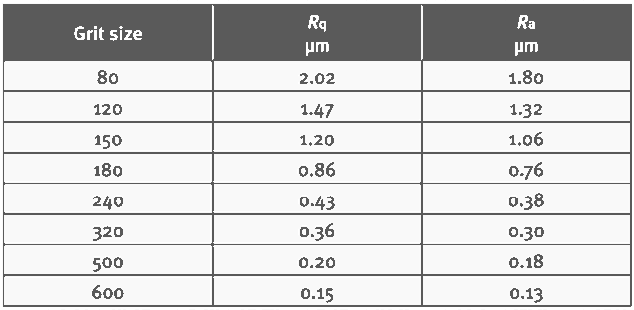

ASTM A312 TP 316L Stainless Steel Pipe Roughness

| Material Surface | Absolute Roughness Coefficient ε mm |

| Aluminum Alloy, Lead | 0.001 – 0.002 |

| Drawn Copper/ Brass | 0.0015 |

| 316L Acier inoxydable | 0.015 |

Traitement thermique

ASTM A312 TP316L grade minimum solution temperature is 1040 degree, then and cool rapidly, it can not be harden by annealing, both seamless and welded stainless steel pipes shall be furnished in heat treatment condition comply to ASTM A312 specification.

316L Stainless Steel Seamless Pipes Applications

Trailers

Échangeurs de chaleur

Équipement de transformation des aliments

Kitchen benches, sinks, troughs, equipment and appliances

construction materials

Threaded fasteners

Chemical containers, including for transport

Automotive trim

Architectural applications

Railway cars

Woven or welded screens for mining, quarrying & water filtration

Stockist Of ASTM A312 TP316L Stainless steel seamless pipe

- ISO9001 ASTM A312 TP321 Stainless steel seamless pipe

- DNV ASTM A312 TP310S Stainless steel seamless pipe

- Bis Certified Ss 304 Seamless Pipes Best Price Supplier

- ASTM A312 TP304 Stainless steel seamless pipe manufacturer

- Storage For ASTM A312 TP317L Stainless steel seamless pipe

304L stainless steel pipe 304L stainless steel seamless pipe 310S stainless steel pipes 321 Acier inoxydable 904L stainless steel pipe 904L stainless steel tubes 2205 2205 tuyau en acier inoxydable 2205 tuyau sans couture en acier inoxydable 2507 tuyau en acier inoxydable duplex 2507 tuyau en acier inoxydable 2507 tuyau sans couture en acier inoxydable 2520 stainless steel tubes AStm A312 stainless stael pipe Spécifications ASTM A312 en acier inoxydable ASTM A312 STAINLESS STEEL SEAMLESS PIPE TUYAU SANS SOUDURE EN ACIER INOXYDABLE ASTM A312 TP304 ASTM A312 TP316L STAINLESS STEEl PIPE Astm a554 stainless steel pipe birmingham wire gauge GTB Bwg Sizes bwg tube tuyau en acier inoxydable duplex gauge bwg tube de chauffage inox press fittings prix sanitary seamless pipe tuyau en acier inoxydable sanitaire sanitary stainless steel tubes Sizes Chart Tuyau en acier inoxydable stainless steel pipefitting tuyaux en acier inoxydable stainless steel sanitary tubes tuyau sans couture en acier inoxydable tuyau de transparence en acier inoxydable tube en acier inoxydable stainless steel welded pipe standard wire gauge Super austénitique 904L en acier inoxydable Tuyau en acier inoxydable TP304 TP304L Stainless steel seamless pipe Tube Chine

Fournisseur de tuyaux en acier inoxydable Wenzhou Kaixin Chine

Fournisseur de tuyaux en acier inoxydable Wenzhou Kaixin Chine