در 10216-5 1.4404 (corresponding to UNS S31603) و 1.4401 (corresponding to UNS S31600) stainless steel seamless pipes are high-performance austenitic stainless steel pipes manufactured in accordance with the European standard در 10216-5, specifically designed for high temperature, high pressure, and highly corrosive media environments. These two materials are widely used in industrial fields such as chemical, energy, shipbuilding, pharmaceuticals, and food processing due to their excellent corrosion resistance, mechanical strength, and processing performance.

Material characteristics

Chemical composition advantages

1.4404 (316L): Low carbon content (≤ 0.03% جف), significantly reducing the risk of intergranular corrosion in welding and high-temperature environments.

1.4401 (316): Contains molybdenum (2.0-2.5% مس) to enhance resistance to pitting and crevice corrosion, suitable for general corrosive environments.

Main components: کلوچه (16.5-18.5%), در (10-13%), providing stable austenite structure and oxidation resistance.

Excellent mechanical performance

Tensile strength: ≥ 520 MPA

Yield strength: ≥ 210 MPA (annealed state)

Elongation rate: ≥ 40%, ensuring good plasticity and formability.

Corrosion resistance and high temperature resistance

Resistant to chlorides, organic acids, and weakly alkaline media, suitable for harsh environments such as seawater and chemical solutions.

Continuous operating temperature range: -196 ° C to+800 ° C (depending on specific operating conditions).

Manufacturing standards and processes

Standard compliance: Strictly follow EN 10216-5, covering chemical composition, mechanical properties, non-destructive testing (ultrasonic/eddy current), and dimensional tolerance requirements.

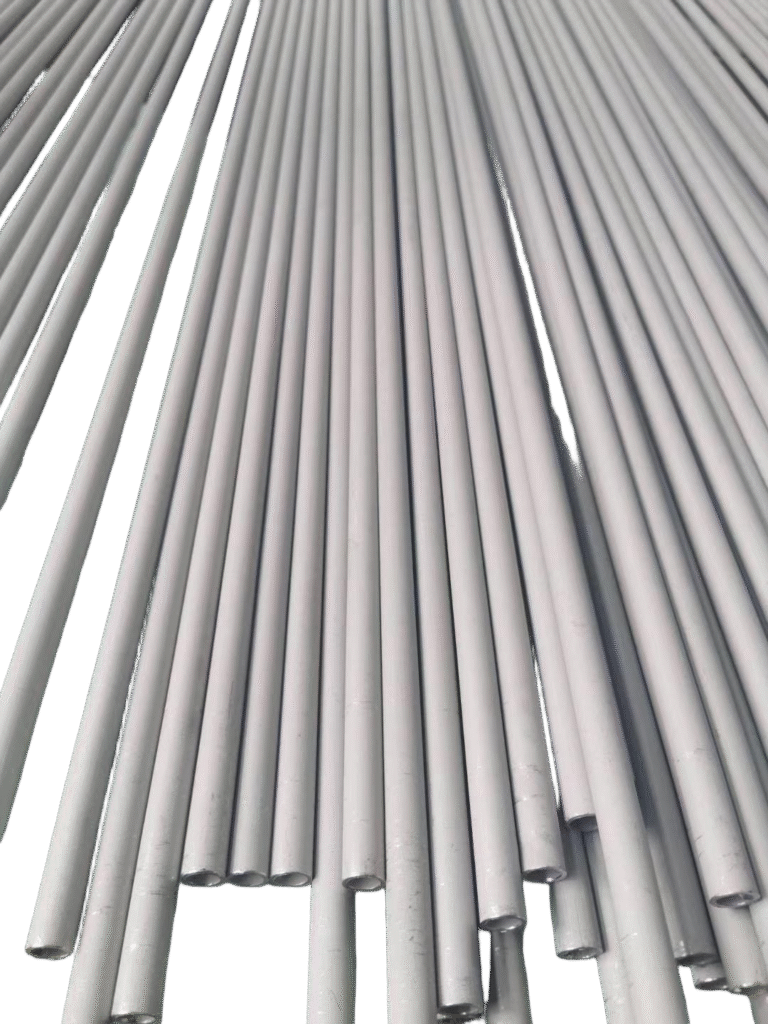

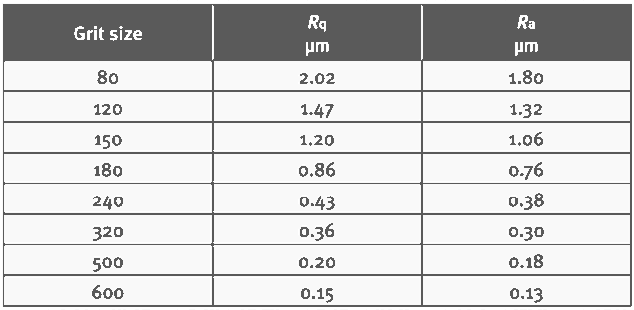

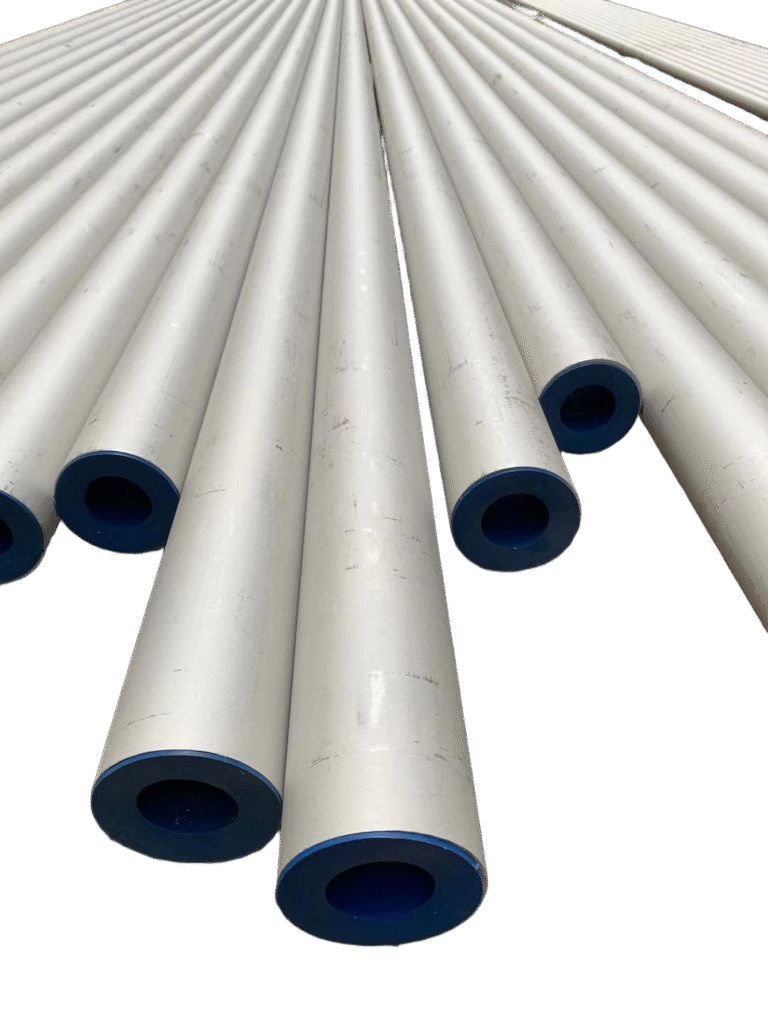

روند تولید: Seamless pipes are manufactured using hot rolling or cold drawing processes to ensure smooth inner walls, uniform wall thickness, and no weak weld areas.

Testing and certification: Support third-party testing (such as T Ü V, SGS), provide material certificates (در 10204 3.1/3.2), and comply with the Pressure Equipment Directive (PED 2014/68/EU).

Typical application areas

Chemical and petrochemical industries: reactors, heat exchanger pipelines, and corrosive fluid transport systems.

Energy and Environmental Protection: Power plant boiler tubes, flue gas desulfurization (FGD) devices, seawater desalination equipment.

Food and medicine: High cleanliness fluid transmission pipelines that comply with FDA/EC1935 hygiene standards.

Ship and ocean engineering: seawater cooling pipelines, ship hydraulic systems.

Product advantages

Reliability and lifespan: Seamless structure avoids leakage risks and extends equipment service life.

Multi functional processability:

supports secondary processing such as welding, bending, and expanding, adapting to complex installation requirements.

Green economy: 100% recyclable, in line with the concept of sustainable manufacturing.

Selection suggestions

How to choose 1.4404 and1.4401 grade Stainless Steel Seamless Pipe Material ?

Choose materials based on the usage environment:

1.4404 (316L): Preferred for welding parts, high carbide sensitive environments, and low-temperature scenarios.

1.4401 (316): Suitable for conventional corrosion resistance requirements from room temperature to medium high temperature without frequent welding.

Service Support

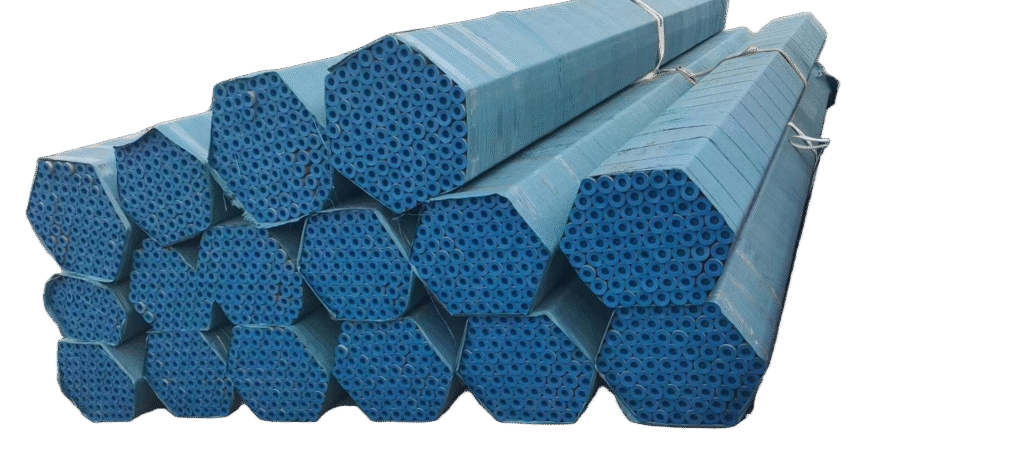

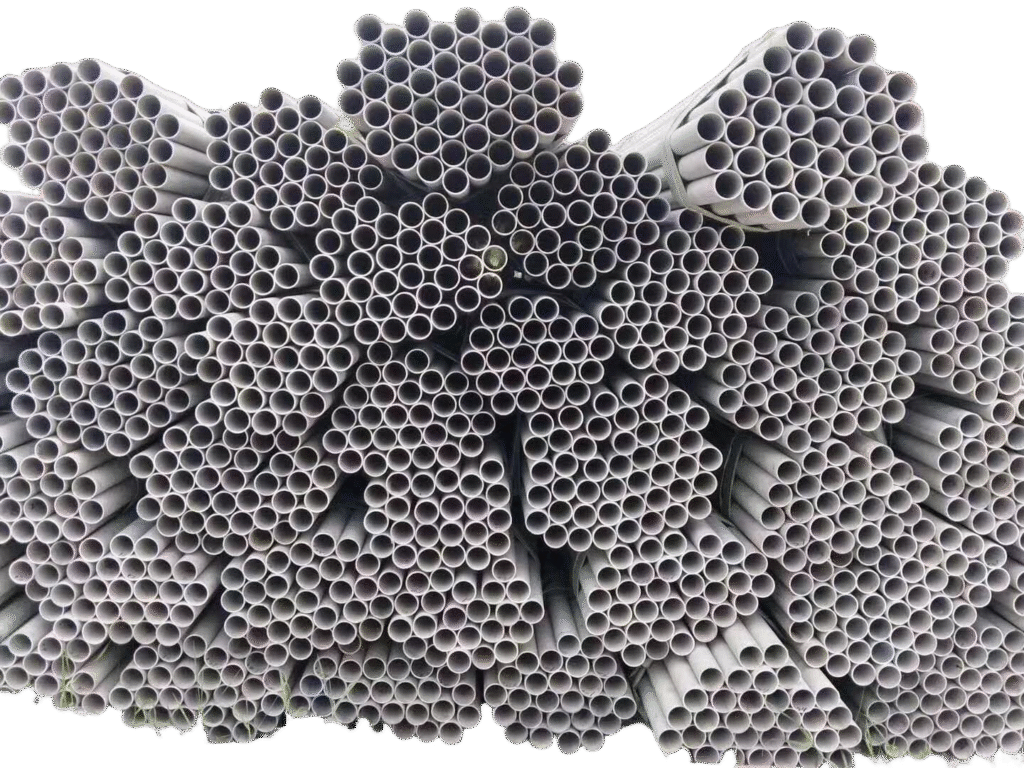

Specification range: Outer diameter 6-762mm, wall thickness 1-50mm, supporting customized production.

Global logistics: providing cutting, beveling, anti-corrosion packaging, and international standard transportation services.

Contact Information

If you need detailed technical parameters or sample support, please contact us and we will provide you with professional material selection solutions

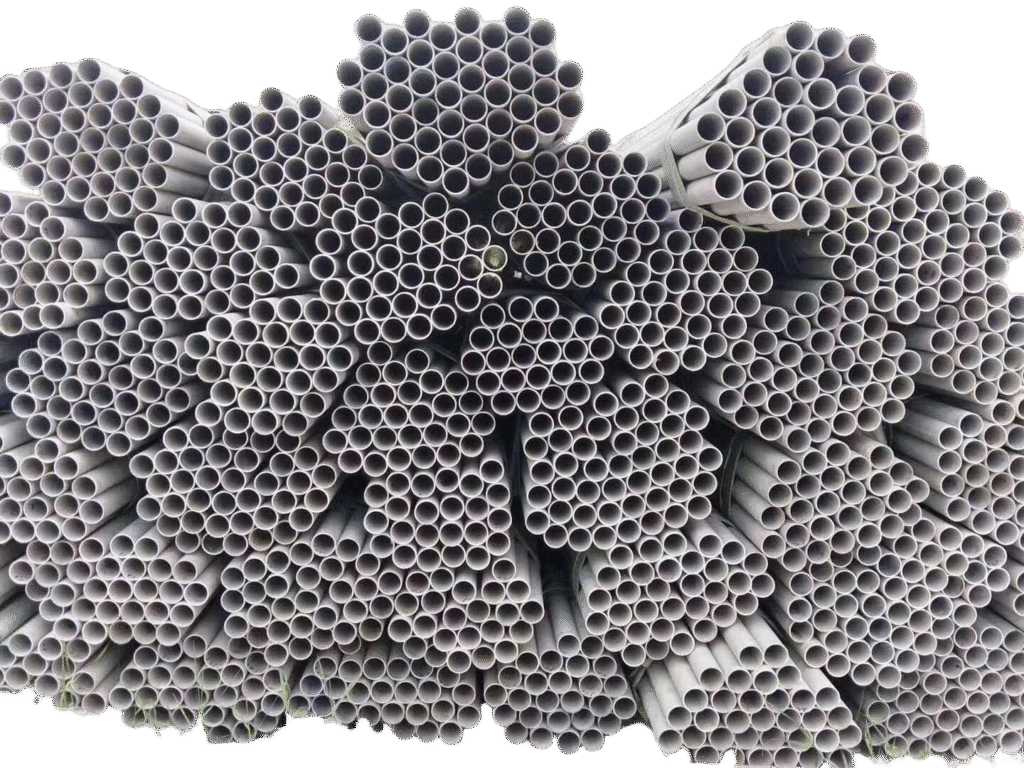

- EN10216-5 stainless steel seamless steel pipes commonly used in industry

- En10216-5 1.4401/1.4404 Stainless Steel Seamless Pipe Tp316L

- ISO9001 ASTM A312 TP321 لوله یکپارچه از جنس استنلس استیل

- DNV ASTM A312 TP310S استیل ضدزنگ لوله یکپارچه

- BIS دارای مجوز SS 304 لوله های بدون درز بهترین تأمین کننده قیمت

304لوله استیل ضد زنگ 304L لوله یکپارچه از جنس استنلس استیل 310لوله های فولادی ضد زنگ 321 فولاد ضد زنگ 904لوله استیل ضد زنگ 904لوله های فولادی ضد زنگ 2205 2205 لوله استیل ضد زنگ 2205 لوله یکپارچه از جنس استنلس استیل 2507 لوله استیل ضد زنگ دوبلکس 2507 لوله استیل ضد زنگ 2507 لوله یکپارچه از جنس استنلس استیل 2520 لوله های استیل ضدزنگ لوله استیل ضد زنگ ASTM A312 مشخصات لوله استیل ضد زنگ ASTM A312 ASTM A312 لوله یکپارچه استیل ضد زنگ لوله بدون درز فولاد ضد زنگ ASTM A312 TP304 ASTM A312 TP316L لوله استیل ضد زنگ لوله استیل ضد زنگ ASTM A554 سنج سیم بیرمنگام BWG اندازه BWG لوله BWG لوله استیل ضد زنگ دوبلکس سنج BWG لوله بازده حرارتی اتصالات مطبوعاتی اینوکس قیمت لوله بدون درز بهداشتی لوله استیل ضدزنگ بهداشتی لوله های استیل ضد زنگ بهداشتی نمودار اندازه لوله های فولادی ضد زنگ لوله کشی از جنس استنلس استیل لوله های استیل ضد زنگ لوله های بهداشتی از جنس استنلس استیل لوله یکپارچه از جنس استنلس استیل لوله یکپارچه استیل ضد زنگ لوله استیل ضد زنگ لوله جوش داده شده از جنس استنلس استیل سنجش سیم استاندارد لوله فولادی ضد زنگ فوق العاده Austenitic 904L لوله استیل ضد زنگ TP304 لوله یکپارچه از جنس استنلس استیل TP304L چین