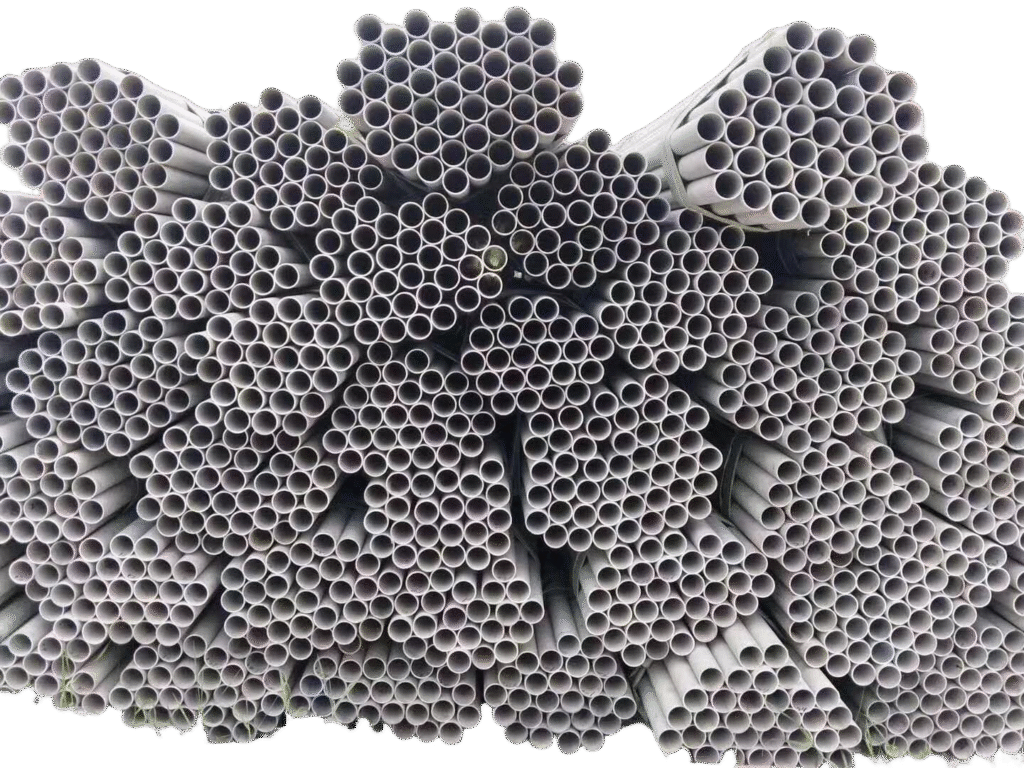

ASTM A789 ASME SA 789 SAF2507 UNS S32750 (EN 10216–5 1.4410) Stainless Steel is super duplex stainless steel with 25% kroom, 4% molübdeen, ja 7% Nikkel, mis on mõeldud nõudlikeks rakendusteks, mis nõuavad erakordset tugevust ja korrosioonikindlust, nagu keemiline protsess, naftakeemiline, ja mereveevarustus. Terasel on suurepärane vastupidavus kloriidipinge korrosioonipragunemisele, kõrge soojusjuhtivus, ja madala soojuspaisumise koefitsient.

ASTM A789 Super Duplex Steel SAF 2507 Tube Specification :

Mõõtmed : ASTM, ASME ja API

ASTM Specification : ASTM A790 / ASME SA790, ASTM A789 / ASME SA A789

ASTM A789 Super Duplex Steel SAF 2507 Tube Size : 1/2″NB TO 12 “NB IN

Seamless Pipe & Tube Size : 1/2” NB – 8” NB

Welded Pipe & Tube Size : 6” NB – 24” NB

Outer Diameter : 6.0-630mm

Paksus : 0.5-45mm

Ajakava : SCH20, SCH30, SCH40, STD, SCH80

Tüüp : Õmblusteta / ACRE / Keevitatud / Valmistatud / CDW

Vorm : Round Pipe/Tube, Square Pipe/Tube, Rectangular Pipe/Tube, Coiled Tube, "U" kuju, Pannikoogi rullid, Hydraulic Tube

Pikkus : Üksik juhuslik, Topeltjuhuslik & Required Length

End : Plain End, Beveled End, Keermestatud

ASTM A789-ASME SA789 SAF2507 Equivalent Material

| Sulam | UNS Designation | Werkstoff NR. | Tehnilised andmed | Afnor | Hinne | FROM | IN | SS |

| 2507 | S32750 | 1.4410 | A/SA789, A/SA790 | Z3 CN 25.06 Az | F53 | X 2 Cr Ni MoN 25.7.4 | 1.4410 | 2328 |

ASTM A789 S32750 (SAF2507) Stainless Steel Tubes Chemical Composition

| C % | Ja % | Mn % | P % | S % | Kr % | sisse % | Mo % | N % | Cu % |

| 0.03 max | 0.8 max | 1.2 max | 0.035 max | 0.02 max | 24.0-26.0 | 6.0-8.0 | 3.0-5.0 | 0.24-0.32 | 0.50 max |

Mehaanilised omadused

| 0.2% Tõestav stress (N/mm2) [ksi] minimum | 550[79.8] |

| Ultimate Tensile Strength (N/mm2) [ksi] minimum | 800 [116] |

| Pikendamine (%) minimum | 25 |

| ardness (HBN) | 270 max |

| Reduction of Cross Section Area (%) | 45 |

| Charpy V-notch Impact at ambient Temp (J) [ft.lb] | 80min [59min] |

| Charpy V-notch Impact at -46°C (J) [ft.lb] | 45av, 35min [33av, 25.8min] |

Füüsikalised omadused

| Tihedus (Kg.m-1) | 7810 |

| Magnetic Permeability | 33 |

| Young’s Modulus (N/mm2) | 199 x 103 |

| Erisoojus, 20°C (J.Kg-1.°K-1) | 475 |

| Fracture Toughness, Kq (MPa.m) | 475 |

| Specific Electrical Resistance, 20°C (µO.m) | 0.80 |

| Thermal conductivity, 20°C (W.m-1.°K-1) | 14.2 |

| Mean coefficient of thermal expansion, 20-100°C (°K-1) | 11.1 x 10-6 |

Pressure Rating of Super Duplex 2507 Toru

| Tube O.D. (In.) | Wall Thickness Of Pipe (Inches) | |||||||

| .028 | .035 | .049 | .065 | .083 | .095 | .109 | .120 | |

| Töörõhk (Psig) | ||||||||

| 1/8 | 7900 | 10100 | ||||||

| 1/4 | 3700 | 4800 | 7000 | 9500 | ||||

| 5/16 | 3700 | 5400 | 7300 | |||||

| 3/8 | 3100 | 4400 | 6100 | |||||

| 1/2 | 2300 | 3200 | 4400 | |||||

| 3/4 | 2200 | 3000 | 4000 | 4600 | ||||

| 1 | 2200 | 2900 | 3400 | 3900 | 4300 | |||

Super dupleks 2507 Tubing Size chart

| Wall | Sizes ( O.D.) |

| .010 | 1/16″ , 1/8″ , 3/16″ |

| .020 | 1/16″ , 1/8″ , 3/16″ , 1/4″ , 5/16″ , 3/8″ |

| .012 | 1/8″ |

| .016 | 1/8″ , 3/16″ |

| .028 | 1/8″ , 3/16″ , 1/4″ , 5/16″ , 3/8″ , 1/2″ , 3/4″ , 1″ , 1 1/2″ , 2″ |

| .035 | 1/8″ , 3/16″ , 1/4″ , 5/16″ , 3/8″ , 7/16″ , 1/2″ , 16″ , 5/8″ , 3/4″ , 7/8″ , 1″ , 1 1/4″ , 1 1/2″ , 1 5/8″ , 2″ , 2 1/4″ |

| .049 | 3/16″ , 1/4″ , 5/16″ , 3/8″ , 1/2″ , 16″ , 5/8″ , 3/4″ , 7/8″ , 1″ , 1 1/8″ , 1 1/4″ , 1 1/2″ , 1 5/8″ , 2″ , 2 1/4″ |

| .065 | 1/4″ , 5/16″ , 3/8″ , 1/2″ , 16″ , 5/8″ , 3/4″ , 7/8″ , 1″ , 1 1/4″ , 1 1/2″ , 1 5/8″ , 1 3/4″ , 2″ , 2 1/2″ , 3″ |

| .083 | 1/4″ , 3/8″ , 1/2″ , 5/8″ , 3/4″ , 7/8″ , 1″ , 1 1/4″ , 1 1/2″ , 1 5/8″ , 1 7/8″ , 2″ , 2 1/2″ ,3″ |

| .095 | 1/2″ , 5/8″ , 1″ , 1 1/4″ , 1 1/2″ , 2″ |

| .109 | 1/2″ , 3/4″ , 1″ , 1 1/4″ , 1 1/2″ , 2″ |

| .120 | 1/2″ , 5/8″ , 3/4″ , 7/8″ , 1″ , 1 1/4″ , 1 1/2″ , 2″ , 2 1/4″ , 2 1/2″ , 3″ |

| .125 | 3/4″ , 1″ , 1 1/4″ , 1 1/2″ , 2″ , 3″ , 3 1/4″ |

| .134 | 1″ |

| .250 | 3″ |

| .375 | 3 1/2″ |

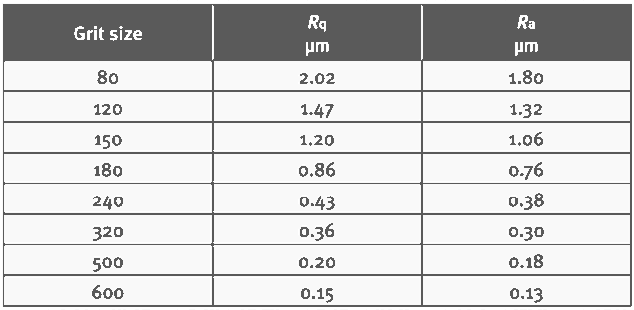

Standard Tolerances of UNS S32750 Tube

Suurus | Standard Tolerances | |||||

| Vorm | Wall | FROM | Length and/or coils | FROM | Lengths | Wall |

| Subsea Umbilical Tubing (ASTM A789 & ASTM A790) | 0.039″ to 0.125″ | 3/8″ to 1-1/2″ | Cut lengths to 60′ Coils to 1-1/2″ OD* | ±0.005″ | Coils to 80,000′ (24,384 m) | ±10% |

| Pressure & Corrosion Tubing (ASTM A789) | 0.010″ – 0.220″ | 1/16″ – 4″ | Cut lengths up – 40′ Coils to 1-1/2″ FROM | <1-1/2″ ±0.005″ 1-1/2″ to 3″ ±0.010″ 3-1/2″to 4″ ±0.015″ | Random Upto +2″ Cuts +1/8″ -0″ Coils to 80,000′ | ±10 |

Processing

Hot Forming

2507 should be hot worked between 1875 F and 2250 F. This should be followed by a solution anneal at 1925F minimum and a rapid air or water quench.

Cold Forming

Enamikku tavalistest roostevabast terasest moodustamismeetodeid saab kasutada külma töötamiseks 2507. Sulamil on suurem saagitugevus ja madalam elastsus kui austeniitilistel terastel, nii et valmistajad võivad leida, et kõrgemad moodustavad jõud, Suurenenud painutamise raadius, ja vajalik on suurenenud toetus kevadiseks. Sügav joonistamine, venitusvormimine, ja sarnaseid protsesse on keerulisem täita 2507 kui austeniitse roostevabast terasest. Moodustamisel nõuab rohkem kui 10% külm deformatsioon, Soovitatav on lahendus ja kustutamine.

Kuumtöötlus

2507 tuleks pärast kuuma või külma moodustumist lahendada ja kustutada. Solution annealing should be done at a minimum of 1925 F. Lõõmutamisele tuleks kohe järgneda kiire õhk või vee kustutamine. Maksimaalse korrosioonikindluse saamiseks, Kuumtöödeldud tooted tuleks marineerida ja loputada.

Rakendused

Electronics

Transport and traffic

Pulp and paper industry

Medicine

Fertilizers

Valve & Pumps

Naftakeemia

Architecture and construction

Aerospace

Nuclear Power

Energy industry

Chemicals industry

Nickel Alloy in Pulp and Paper

Motor industry

Food and drink

304L stainless steel pipe 304L stainless steel seamless pipe 310S stainless steel pipes 321 Roostevaba teras 904L stainless steel pipe 904L stainless steel tubes 2205 2205 roostevabast terasest toru 2205 roostevabast terasest õmblusteta toru 2507 dupleks roostevabast terasest toru 2507 roostevabast terasest toru 2507 roostevabast terasest õmblusteta toru 2520 stainless steel tubes AStm A312 stainless stael pipe ASTM A312 roostevabast terasest torude spetsifikatsioonid ASTM A312 STAINLESS STEEL SEAMLESS PIPE ASTM A312 TP304 ROOSTEVABASEST TERASEST ÕMBETETA TORU ASTM A312 TP316L STAINLESS STEEl PIPE Astm a554 stainless steel pipe birmingham wire gauge BWG Bwg Sizes bwg tube dupleks roostevabast terasest toru gauge bwg Kuumutage exhcange'i toru inox press fittings hind sanitary seamless pipe Sanitaar roostevabast terasest toru sanitary stainless steel tubes Sizes Chart Roostevabast terasest toru stainless steel pipefitting roostevabast terasest torud stainless steel sanitary tubes roostevabast terasest õmblusteta toru roostevabast terasest õmblusteta toru roostevabast terast toru roostevabast terasest keevitatud toru standard wire gauge superausteniit 904L roostevabast terasest toru TP304 roostevabast terasest toru TP304L Stainless steel seamless pipe Toru Hiina

Roostevabast terasest torude tarnija Wenzhou Kaixin Hiinas

Roostevabast terasest torude tarnija Wenzhou Kaixin Hiinas