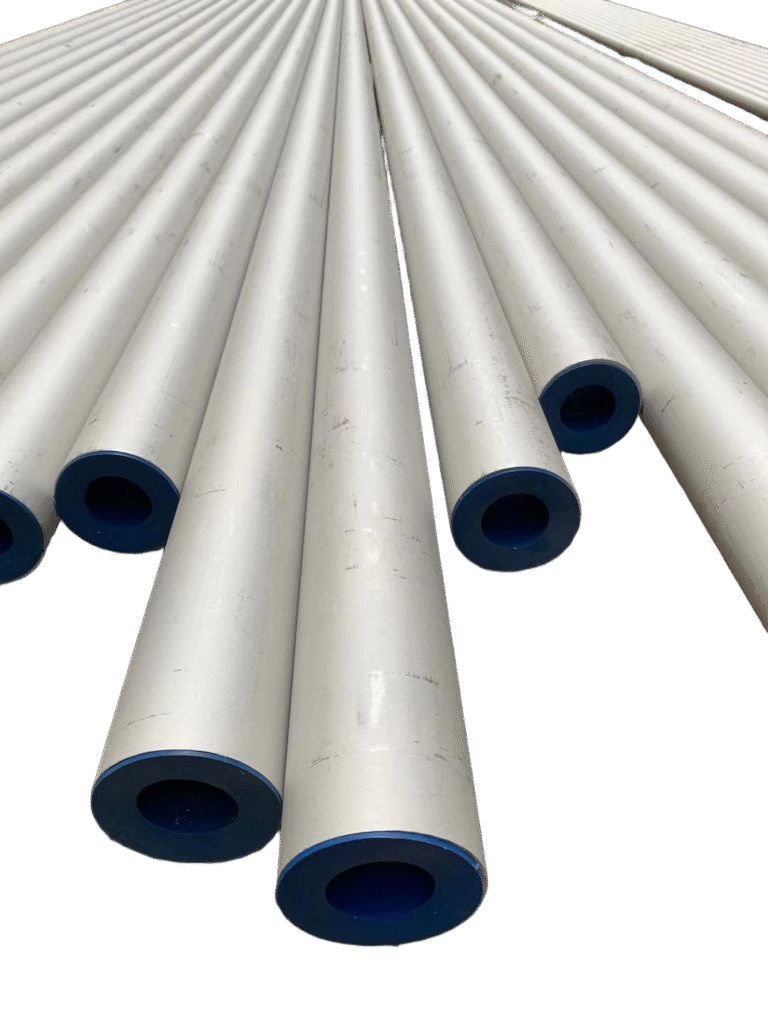

Top-quality SS 310S stainless steel seamless pipe & pipe fittings WENZHOU KAIXIN METAL CO., LTD in Wenzhou is your premier supplier! We provide seamless pipes and pipeline goods. Get superior stainless steel products. Visit us to learn more and book your order:

ASTM A312 310s Stainless Steel Seamless Pipe is known to be the widely used stainless steel. The SS 310S ERW Pipe has excellent forming attributes as well as corrosion resistance. 310S Stainless Steel Welded Pipe is mostly utilized in food processing, fertilizer industries, kitchen wares and many more. Alloy 310S Pipe is available in the market in different kinds such as square, honed tubes, round, rectangle and hydraulic. También, Acero inoxidable 310 Welded Pipe is reached for testing purposes in the government approved laboratories. The ASTM A213 TP 310S Tube test is done on it like MTC and IBR. Another thing is that the pipe is a superb blend of good ductility and weld ability with high-temperature attributes.

También, the ASTM A312 TP310S Stainless Steel Seamless Pipe resists oxidation in constant service at the temperature above 1150 degree Celsius given eliminating sulfur gases that are not available. The ASTM A213 TP 310S Tube is being utilized for intermittent services at the temperature above 1040 degree Celsius.

ASTM A312 TP 310S Stainless Steel Pipes Specifications

Presupuesto:ASTM A 312 / ASME SA 312

Dimensiones:ASTM, ASME y API

SS 310 / 310S Pipes :1/2″ NB – 16″ NB

ACRE 310 / 310S Pipes:1/2″ NB – 24″ NB

EFW 310 / 310S Pipes:6″ NB – 100″ NB

Tamaño :1/8″NB TO 30″NB IN

Especializado en:Tamaño de diámetro grande

Cronograma:SCH20, SCH30, SCH40, ETS, SCH80, XS, SCH60, SCH80, SCH120, SCH140, SCH160, XXS

Tipo :Sin costura / ACRE / soldado / fabricado / LSAW Pipes

Forma:Redondo, Square, Rectangular, Hydraulic Etc

Longitud:Single Random, Double Random & Cut Length.

End:Plain End, Beveled End, Treaded

Stainless Stee 310S Sin costura Pipes Equivalent Grades

Equivalent Grade Of TP310S Stainless Steel Seamless Pipe

| Estándar | SS 310S |

| WERKSTOFF NR. | 1.4845 |

| A NOSOTROS | S31008 |

| ÉL | SUS 310S |

| Licenciatura | 310S16 |

| GOST | 20Ch23N18 |

| EN | X8CrNi25-2 |

Chemical Composition of ASTM A312 TP310S Stainless Steel Seamless Pipes

Chemical Compostion Chart of Each Element

| Calificación | C | Minnesota | Y | PAG | S | cr | Mes | En | norte | |

| 310S | mín.. máximo. | – 0.08 | – 2.00 | – 1.50 | – 0.045 | – 0.030 | 24.0 26.0 | – | 19.0 22.0 | – |

Mechanical Properties of ASTM A312 310S Stainless Steel Seamless Pipes

Propiedades mecánicas For Regular 310 Steel Pipe Chart

| Calificación | Resistencia a la tracción (MPa) mín. | Fuerza de producción 0.2% Proof (MPa) mín. | Alargamiento (% in 50mm) mín. | Dureza | |

| Rockwell B (HR B) máximo | Brinell (HB) máximo | ||||

| 310S | 515 | 205 | 40 | 95 | 217 |

ASTM A312 TP310S Stainless Steel Seamless Pipes Physical PropertiesStainless Steel

Physical properties of 310s grade stainless steel in the annealed condition

| Calificación | Densidad (kg/m3) | Elastic Modulus (GPa) | Mean Coefficient of Thermal Expansion(μm/m/°C) | Conductividad térmica(W/m.K) | Specific Heat 0-100°C (J/kg.K) | Resistividad eléctrica (nΩ.m) | |||

| 0-100°C | 0-315°C | 0-538°C | at 100°C | at 500°C | |||||

| 310S | 7750 | 200 | 15.9 | 16.2 | 17.0 | 14.2 | 18.7 | 500 | 720 |

Tolerance For Out Dia Chart of ASTM A312 Tp310S Pipe

| 310S Pipe OD | 310S Pipe Tolerance |

| 38 to 60mm | +/- 0.20milímetros |

| 4 to 35mm | +/- 0.08milímetros |

| 60 and above | +/- 0.25milímetros |

| 35 to 38mm | +/- 0.15milímetros |

ASTM A312 TP310s Pipe Size Chart

| Stainless Steel 310S Pipe OD milímetros | Pipe WT milímetros | en. | Sch | Kg/m |

| 13.72 | 1.65 | 1/4 | 10S | 0.50 |

| 13.72 | 2.24 | 1/4 | 40S | 0.64 |

| 13.72 | 3.02 | 1/4 | 80S | 0.81 |

| 17.15 | 1.65 | 3/8 | 10S | 0.64 |

| 17.15 | 2.31 | 3/8 | 40S | 0.86 |

| 17.15 | 3.20 | 3/8 | 80S | 1.12 |

| 21.34 | 2.11 | 1/2 | 10S | 1.02 |

| 21.34 | 2.77 | 1/2 | 40S | 1.29 |

| 21.34 | 3.73 | 1/2 | 80S | 1.65 |

| 26.67 | 2.11 | 3/4 | 10S | 1.30 |

| 26.67 | 2.87 | 3/4 | 40S | 1.71 |

| 26.67 | 3.91 | 3/4 | 80S | 2.23 |

| 33.40 | 2.77 | 1 | 10S | 2.13 |

| 33.40 | 3.38 | 1 | 40S | 2.54 |

| 33.40 | 4.55 | 1 | 80S | 3.29 |

| 33.40 | 6.352) | 1 | 160 | 4.30 |

| 42.16 | 2.77 | 1¼ | 10S | 2.73 |

| 42.16 | 3.56 | 1¼ | 40S | 3.44 |

| 42.16 | 4.85 | 1¼ | 80S | 4.53 |

| 42.16 | 6.352) | 1¼ | 160 | 5.69 |

| 48.26 | 2.77 | 1½ | 10S | 3.16 |

| 48.26 | 3.68 | 1½ | 40S | 4.11 |

| 48.26 | 5.08 | 1½ | 80S | 5.49 |

| 60.33 | 2.77 | 2 | 10S | 3.99 |

| 60.33 | 3.91 | 2 | 40S | 5.52 |

| 60.33 | 5.54 | 2 | 80S | 7.60 |

| 60.33 | 8.742) | 2 | 160 | 11.29 |

| 73.03 | 3.05 | 2½ | 10S | 5.35 |

| 73.03 | 5.16 | 2½ | 40S | 8.77 |

| 73.03 | 7.01 | 2½ | 80S | 11.59 |

| 88.90 | 3.05 | 3 | 10S | 6.56 |

| 88.90 | 5.49 | 3 | 40S | 11.47 |

| 88.90 | 7.62 | 3 | 80S | 15.51 |

| 88.90 | 11.132) | 3 | 160 | 21.67 |

| 101.60 | 3.05 | 3½ | 10S | 7.53 |

| 101.60 | 5.74 | 3½ | 40S | 13.78 |

| 101.60 | 8.08 | 3½ | 80S | 18.92 |

| 114.30 | 3.05 | 4 | 10S | 8.50 |

| 114.30 | 6.02 | 4 | 40S | 16.32 |

| 114.30 | 8.56 | 4 | 80S | 22.67 |

| 114.30 | 13.492) | 4 | 160 | 34.05 |

| 141.30 | 6.55 | 5 | 40S | 22.10 |

| 141.30 | 9.53 | 5 | 80S | 31.44 |

| 141.30 | 15.882) | 5 | 160 | 49.87 |

| 168.28 | 3.4 | 6 | 10S | 14.04 |

| 168.28 | 7.11 | 6 | 40S | 28.69 |

| 168.28 | 10.97 | 6 | 80S | 43.21 |

| 168.28 | 14.27 | 6 | 120 | 54.75 |

| 168.28 | 18.262) | 6 | 160 | 68.59 |

| 219.08 | 8.18 | 8 | 40S | 43.20 |

| 219.08 | 12.7 | 8 | 80S | 65.63 |

| 219.08 | 18.23 | 8 | 120 | 91.30 |

| 219.08 | 23.012) | 8 | 160 | 112.97 |

Stainless Steel 310S Pressure Rating

| Stainless 310S Pressure Rating(psig) | ||||||||||

| Stainless 310S Tamaño (pulgadas) | Stainless 310S Schedule | Temperature(°F) | ||||||||

| 100 | 200 | 300 | 400 | 500 | 600 | 650 | 700 | 750 | ||

| 1″ | 40 | 3048 | 2629 | 2362 | 2171 | 2019 | 1924 | 1867 | 1824 | 1810 |

| 80 | 4213 | 3634 | 3265 | 3002 | 2791 | 2659 | 2580 | 2528 | 2501 | |

| 160 | 6140 | 5296 | 4759 | 4375 | 4068 | 3876 | 3761 | 3684 | 3646 | |

| 1 1/2″ | 40 | 2257 | 1947 | 1750 | 1608 | 1496 | 1425 | 1383 | 1354 | 1340 |

| 80 | 3182 | 2744 | 2466 | 2267 | 2108 | 2009 | 1949 | 1909 | 1889 | |

| 160 | 4619 | 3984 | 3580 | 3291 | 3060 | 2916 | 2829 | 2772 | 2743 | |

| 2″ | 40 | 1902 | 1640 | 1474 | 1355 | 1260 | 1201 | 1165 | 1141 | 1129 |

| 80 | 2747 | 2369 | 2129 | 1957 | 1820 | 1734 | 1682 | 1648 | 1631 | |

| 160 | 4499 | 3880 | 3486 | 3205 | 2980 | 2840 | 2755 | 2699 | 2671 | |

| 3″ | 40 | 1806 | 1558 | 1400 | 1287 | 1196 | 1140 | 1106 | 1084 | 1072 |

| 80 | 2553 | 2202 | 1979 | 1819 | 1691 | 1612 | 1564 | 1532 | 1516 | |

| 160 | 3840 | 3312 | 2976 | 2736 | 2544 | 2424 | 2352 | 2304 | 2280 | |

| 4″ | 40 | 1531 | 1321 | 1187 | 1091 | 1014 | 967 | 938 | 919 | 909 |

| 80 | 2213 | 1909 | 1715 | 1577 | 1466 | 1397 | 1355 | 1328 | 1314 | |

| 160 | 3601 | 3106 | 2791 | 2566 | 2386 | 2273 | 2206 | 2161 | 2138 | |

| 5″ | 40 | 1342 | 1158 | 1040 | 956 | 889 | 847 | 822 | 805 | 797 |

| 80 | 1981 | 1709 | 1535 | 1411 | 1312 | 1250 | 1213 | 1189 | 1176 | |

| 160 | 3414 | 2945 | 2646 | 2433 | 2262 | 2155 | 2091 | 2049 | 2027 | |

| 6″ | 40 | 1219 | 1052 | 945 | 869 | 808 | 770 | 747 | 732 | 724 |

| 80 | 1913 | 1650 | 1483 | 1363 | 1267 | 1208 | 1172 | 1148 | 1136 | |

| 160 | 3289 | 2836 | 2549 | 2343 | 2179 | 2076 | 2014 | 1973 | 1953 | |

| 8″ | 40 | 1073 | 926 | 832 | 765 | 711 | 678 | 657 | 644 | 637 |

| 80 | 1692 | 1459 | 1311 | 1205 | 1121 | 1068 | 1036 | 1015 | 1005 | |

| 160 | 3175 | 2738 | 2460 | 2262 | 2103 | 2004 | 1944 | 1905 | 1885 | |

| 10″ | 40 | 974 | 840 | 755 | 694 | 645 | 615 | 596 | 584 | 578 |

| 80 | 1609 | 1388 | 1247 | 1147 | 1066 | 1016 | 986 | 966 | 956 | |

| 160 | 3147 | 2714 | 2439 | 2242 | 2085 | 1986 | 1927 | 1880 | 1868 | |

Corrosion Resistance:

Good aqueous corrosion resistance due to high chromium content

Good resistance to oxidizing and carburizing atmospheres

Excellent resistance to corrosion at normal temperatures

Heat Resistance:

Good resistance to oxidation in intermittent service up to 1040°C temperatures, and in continuous service up to 1150°C.

Good resistance to thermal fatigue and cyclic heating.

Widely used in areas with elevated temperatures, and sulphur-dioxide gas.

Continuous use in 425-860°C temperature range can deteriorate aqueous corrosion resistance due to carbide precipitation.

Generally used in applications with temperatures starting from about 800 or 900°C.

Fabricación:

Mostly used in heat treatment and process industries in high temperature and corrosive environments

Can be easily roller-formed, stamped, and drawn

Usually fabricated into complex structures

Calificación 310 pipes harden after severe forming operations. Hence, it should be followed by annealing

Stainless Steel TP310S Seamless Pipes Application

SS 310S Seamless Pipes are known to deliver exceptional performance and are generally developed for meeting the demands. We offer a broad range of A312 / SA312 Austenitic Stainless Steel 310S Piping through a worldwide network of stock-keeping branches. These Seamless Pipe is use in various industries like :

Stainless Steel 310S Seamless Pipes uses in Water Supply Systems

Austenitic SS TP310S Seamless Pipes uses in Power Plant

TP310S Steel Seamless Piping uses in Paper & Industria de la celulosa

SS 310S Seamless Pipes uses in General Purpose Applications

Stainless Steel 310S Seamless Pipes uses in Fabrication Industry

Austenitic steel 310S Seamless Pipes uses in Food Processing Industry

Stainless Steel TP310S Seamless Pipes uses in Structural Pipe

ASTM A312 Stainless Steel Pipes uses in Oil and Gas Pipeline

ASME SA312 Seamless Piping uses in Chemical Industry

SUS 310S Stainless Steel Seamless Pipes uses in Plumbing

AISI 310S Seamless Stainless Steel Pipes uses in Heating

- ISO9001 ASTM A312 TP321 Stainless steel seamless pipe

- DNV ASTM A312 TP310S Stainless steel seamless pipe

- Bis Certified Ss 304 Seamless Pipes Best Price Supplier

- ASTM A312 TP304 Stainless steel seamless pipe manufacturer

- Storage For ASTM A312 TP317L Stainless steel seamless pipe

304L stainless steel pipe 304L stainless steel seamless pipe 310S stainless steel pipes 321 Acero inoxidable 904L stainless steel pipe 904L stainless steel tubes 2205 2205 tubería de acero inoxidable 2205 stainless steel seamless pipe 2507 duplex stainless steel pipe 2507 tubería de acero inoxidable 2507 stainless steel seamless pipe 2520 stainless steel tubes AStm A312 stainless stael pipe Especificaciones de tubería de acero inoxidable ASTM A312 ASTM A312 STAINLESS STEEL SEAMLESS PIPE TUBO INCONSÚTIL DE ACERO INOXIDABLE ASTM A312 TP304 ASTM A312 TP316L STAINLESS STEEl PIPE Astm a554 stainless steel pipe birmingham wire gauge BWG Bwg Sizes bwg tube duplex stainless steel pipe gauge bwg Tubo de exhrocange de calor inox press fittings price sanitary seamless pipe tubería de acero inoxidable sanitario sanitary stainless steel tubes Sizes Chart Tubería de acero inoxidable stainless steel pipefitting tubos de acero inoxidable stainless steel sanitary tubes stainless steel seamless pipe tubería sin costuras de acero inoxidable tubo de acero inoxidable tubo soldado de acero inoxidable standard wire gauge super austenitic 904L stainless steel pipe Tubería de acero inoxidable TP304 TP304L Stainless steel seamless pipe Tube China

Proveedor de tubos de acero inoxidable Wenzhou Kaixin China

Proveedor de tubos de acero inoxidable Wenzhou Kaixin China