Highly corrosive environment? Choose stainless steel conduit!

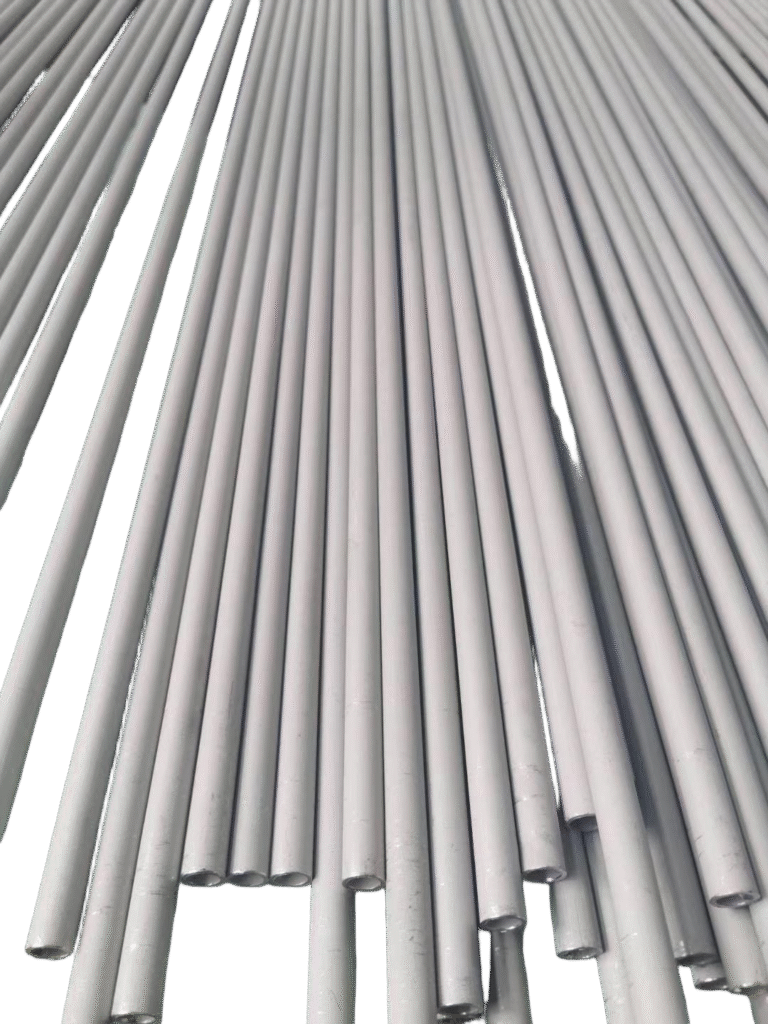

Stainless steel conduit a type of pipe designed specifically for highly corrosive environments, mainly used in factories, new energy lithium power plants, food factories, clean workshops, nuclear power plants, distilleries, soy sauce factories, precision electronics factories, and other places. These places usually have characteristics such as acidic and alkaline corrosion, high temperature, high dust, vibration or fire hazards, and may even pose a risk of explosion.

The characteristics of stainless steel conduit

The characteristics of stainless steel conduit include:

Lightweight: easy to handle and install.

Good corrosion resistance: able to resist acid and alkali corrosion and will not rust.

Strong impact resistance: able to withstand certain physical impacts.

High strength: Ensure the stability of the circuit connection.

Soft and resilient: easy to bend, suitable for different wiring needs.

Stainless steel conduit is particularly suitable for use in harsh environments due to its excellent mechanical properties, corrosion resistance, and weather resistance. It not only protects the circuit, but also prevents it from breaking due to corrosion. Zusätzlich, the construction process of stainless steel conduit is simple, fast, cost-effective, and environmentally friendly.

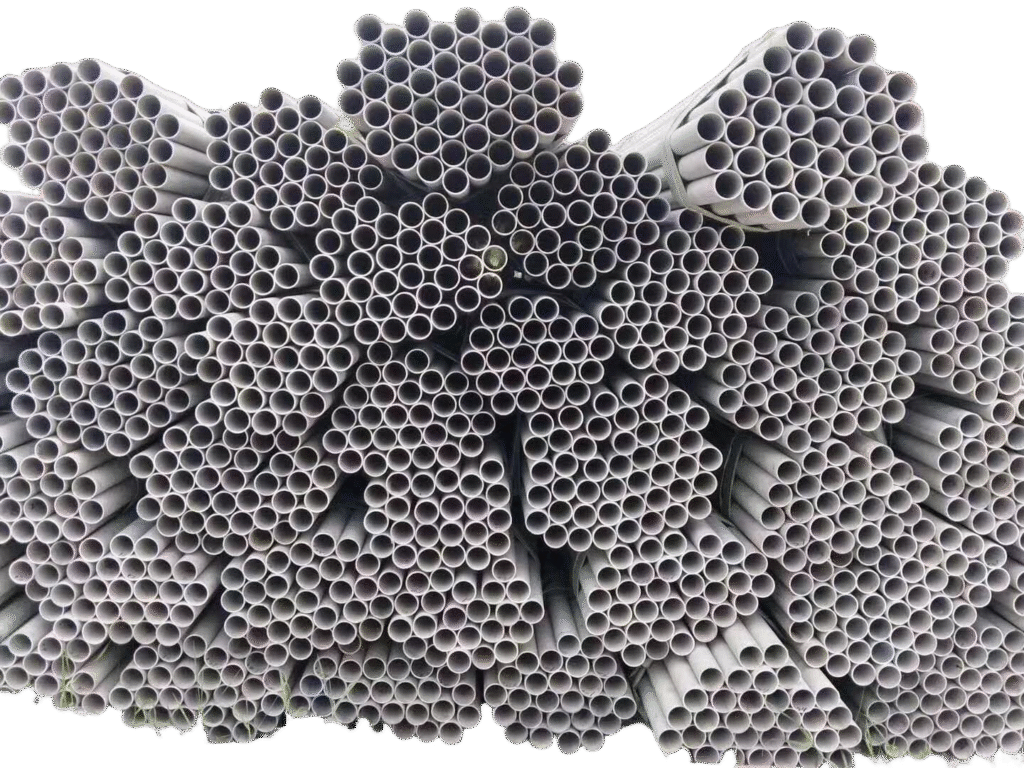

EMT Tubing is available in trade sizes 1/2″ through 4″. Our Electrical Metallic Tubing precisely manufactured from high grade stainless steel strip steel for excellent durability, easy bending and quick cutting. Der Edelstahl conduit EMT is outside polished for corrosion protection. EMT pipe is commonly installed by use of set-screw or compression type connectors and couplings.

EMT, Electrical Metallic Tubing, UL 797, CSA C22.2, ANSI C80.3 Size Chart

| Nominal Size (Zoll) | Außendurchmesser (mm) | Länge (mm) | Länge (Zoll) | Gewicht (Kg/Pc) | Bundle (Pcs) |

|---|---|---|---|---|---|

| 1/2″ | 21.1 | 3,050 | 10” | 3.08 | 20 |

| 3/4″ | 26.7 | 3,050 | 10” | 3.95 | 20 |

| 1″ | 33.4 | 3,050 | 10″ | 6.56 | 10 |

| 1-1/4″ | 42.2 | 3,050 | 10” | 8.39 | 5 |

| 1-1/2″ | 48.3 | 3,050 | 10” | 9.69 | 5 |

| 2″ | 60.3 | 3,050 | 10” | 12.29 | 2 |

| 3″ | 88.9 | 3,050 | 10” | 26.23 | 1 |

| 4″ | 114.2 | 3,050 | 10” | 34.12 | 1 |

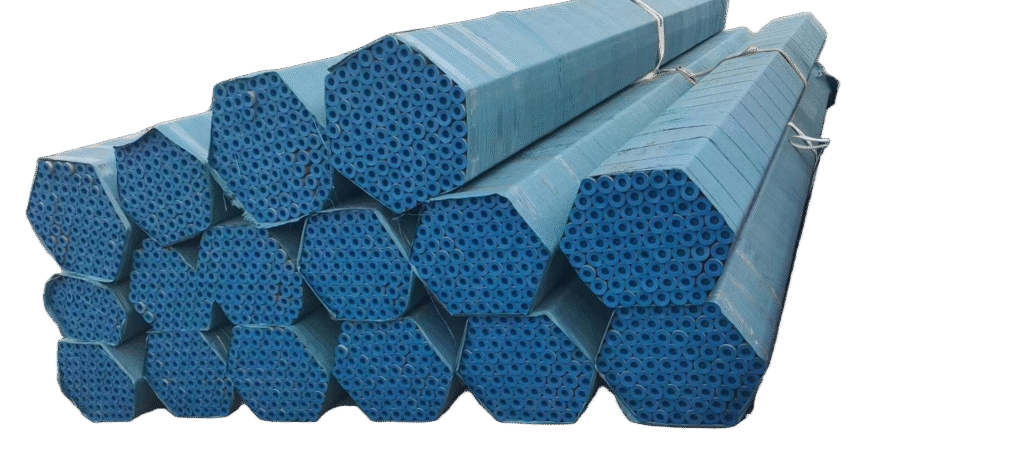

BS4568/EN 61386 class 4 conduit Size Chart

| Nominal Size | Außendurchmesser (mm) | Wall thickness (mm) | Länge (m) | Thread length (mm) | ||

| Maximum | Minimum | Maximum | ||||

| 20 | 19.70 | 20.00 | 1.6 ± 0.15 | 3.75 | 13.0 | 15.0 |

| 25 | 24.60 | 25.00 | 1.6 ± 0.15 | 3.75 | 16.0 | 18.0 |

| 32 | 31.60 | 32.00 | 1.6 ± 0.15 | 3.75 | 18.0 | 20.0 |

| 40 | 39.50 | 40.00 | 1.6 ± 0.15 | 3.75 | 19.0 | 20.0 |

| 50 | 49.50 | 50.00 | 1.6 ± 0.15 | 3.75 | 19.0 | 20.0 |

- Surface treatment is smooth, have good resistant to corrosion

- ·Threaded at both ends

- ·Each length supplied with one coupler and one plastic thread protector cap

- ·Available in 20mm to 50mm diameter and 3.75m length

- ·Manufactured in accordance with BS4568

BS4568/EN 61386 class 4 conduit usually use in industrial, commercial, and residential buildings to be installed indoors and outdoors to protect wires and cables.

Stainless Steel Conduit Install

When installing stainless steel conduit, the following points should be noted:

Surface cleaning and polishing: Before installation, the pipes need to be cleaned and polished to ensure installation quality.

Strictly follow the cutting diagram for cutting: When cutting, it is necessary to strictly follow the cutting diagram to avoid errors.

Keep the pipe straight: During installation, the pipe should be kept straight and the bending angle should be uniform to ensure the stability of the line connection.

Stainless steel conduit is not only suitable for new buildings, but also for the renovation of old buildings‘ wiring, which can effectively improve the stability and safety of the wiring

Differences between UL and CSADifferences between UL and CSA certifications in selecting stainless steel conduit

What is EMT Meaning?

EMT is short for Electrical Metallic Tubing. Electrical Metallic tube, also commonly called thin-wall, a steel raceway of circular cross section, which is unthreaded, and nominally 10′ long.Our Stainless Steel Tube of electrical manufactured according to UL 797, CSA C22.2 NO.83.1 and ANSI C80.3, Electrical Metallic Tubing – Stainless Steel.