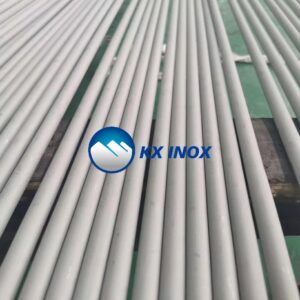

ASTM A269 TP304 Stainless steel seamless tube in china

ASTM A269 TP304 stainless steel seamless tubes are essential in many industries. They offer excellent corrosion resistance and durability.

These tubes are a top choice for high-pressure and high-temperature applications.

Manufactured without welds, seamless tubes ensure a smooth interior surface. This design reduces friction and enhances flow efficiency.

The seamless construction also minimizes the risk of leaks, ensuring system integrity.

China is a leading producer of these high-quality tubes. The country’s manufacturers provide competitive pricing and quick delivery.

This makes China an attractive source for procurement managers and engineers.

ASTM A269 TP304 tubes meet international quality standards. They are versatile, reliable, and suitable for various applications, from chemical processing to food and beverage industries.

What is ASTM A269 TP304 Stainless Steel Seamless Tube?

ASTM A269 TP304 stainless steel seamless tubes are a standard specification for quality stainless steel tubing. Known for their strength, these tubes are popular among industrial professionals.

They are specifically designed to withstand harsh environments.

The TP304 grade is an austenitic stainless steel. It contains 18% chromium and 8% nickel. This composition enhances its resistance to oxidation and corrosion.

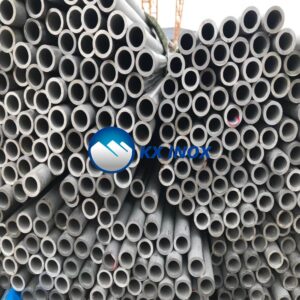

The seamless design refers to tubes without welds. These tubes are formed through a rotary piercing or extrusion process. This method ensures uniformity and strength.

Common uses for ASTM A269 TP304 tubes include:

- Hemijska obrada

- Oil and gas pipelines

- Food and beverage equipment

Seamless tubes are chosen for high-pressure applications. They cater to industries that demand stringent quality and performance. \The seamless structure ensures stability and dependability even under extreme conditions.

Key Specifications and Chemical Composition

ASTM A269 TP304 stainless steel seamless tubes conform to rigorous quality standards. These specifications ensure the material’s suitability for demanding environments.

They are tested to meet international benchmarks.

The chemical composition plays a vital role in the tube’s performance. TP304 stainless steel primarily consists of chromium and nickel.

These elements together enhance its corrosion resistance and durability.

The typical chemical breakdown of TP304 stainless steel is as follows:

- Chromium: 18%

- Nikl: 8%

- Carbon: Max 0.08%

- Manganese: Max 2%

- Silicon: Max 1%

- Phosphorus: Max 0.045%

- Sulfur: Max 0.03%

Such a composition ensures robust resistance to adverse elements. The alloy’s purity and quality contribute to its broad industrial applications.

Mechanical and Physical Properties

ASTM A269 TP304 stainless steel seamless tubes exhibit impressive mechanical properties. They possess high tensile and yield strengths.

These characteristics make them suitable for challenging applications.

The physical properties of TP304 stainless steel are equally commendable. The material is known for its excellent thermal conductivity and low thermal expansion.

This makes it effective for temperature-sensitive projects.

Key mechanical properties include:

- Zatezna čvrstoća: Around 515 MPa

- Snaga prinosa: Approximately 205 MPa

- Izduženje: Roughly 35%

- Tvrdoća: Max 201 HB

These properties ensure the tubing’s reliability under stress. Their effectiveness in resisting deformation and wear is notable.

The versatility of TP304 tubes is due to these strong mechanical foundations.

Manufacturing Process of Seamless Stainless Tubes

The manufacturing of seamless stainless tubes is a precise process. It involves creating tubes without any welds. This enhances their strength and reliability.

The process begins with a solid steel billet. This billet is heated to high temperatures. Then, it undergoes either extrusion or rotary piercing.

Key steps in the seamless tube production include:

- Heating: The billet is heated to soften it.

- Piercing: A mandrel pierces the billet to form a hollow tube.

- Rolling: The tube is elongated and formed to the desired size.

- Cooling: The tube is gradually cooled for structural integrity.

This seamless design ensures a smooth internal surface. It minimizes friction and maximizes flow efficiency. The absence of welds provides higher pressure resistance.

Advantages of ASTM A269 TP304 Seamless Tubes

The ASTM A269 TP304 seamless tubes offer numerous advantages. They are renowned for their exceptional corrosion resistance. This makes them ideal for various industrial environments.

These tubes are highly durable and maintain their form over time. Their seamless design ensures leak-proof operation. This boosts the reliability of systems incorporating these tubes.

Some key benefits include:

- Otpornost na koroziju: Suitable for harsh environments.

- High Strength: Able to withstand high pressure and temperature.

- Smooth Surface: Enhances flow efficiency, reducing turbulence.

Dodatno, the tubes are easy to clean and maintain. This makes them suitable for sanitary applications. Their aesthetic appeal also suits architectural uses.

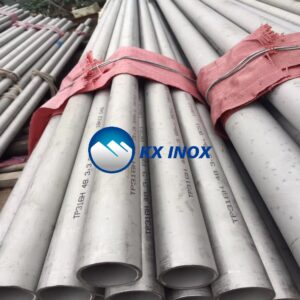

Common Applications in Industry

The ASTM A269 TP304 seamless tubes are used widely across various industries. Their versatility and robustness make them a top choice.

These tubes are vital in environments requiring durability and reliability.

In chemical processing, the tubes resist corrosion and heat. This makes them suitable for handling aggressive substances. They also excel in maintaining purity and integrity.

Industries that commonly use these tubes include:

- Chemical Processing: For transporting reactive compounds.

- Food and Beverage: Ensures hygiene and prevents contamination.

- Nafta i gas: Handles high pressure and temperature conditions.

Dodatno, these tubes find a place in the pharmaceutical industry. They ensure high cleanliness standards are met.

Their usage spans a broad spectrum, highlighting their adaptability.

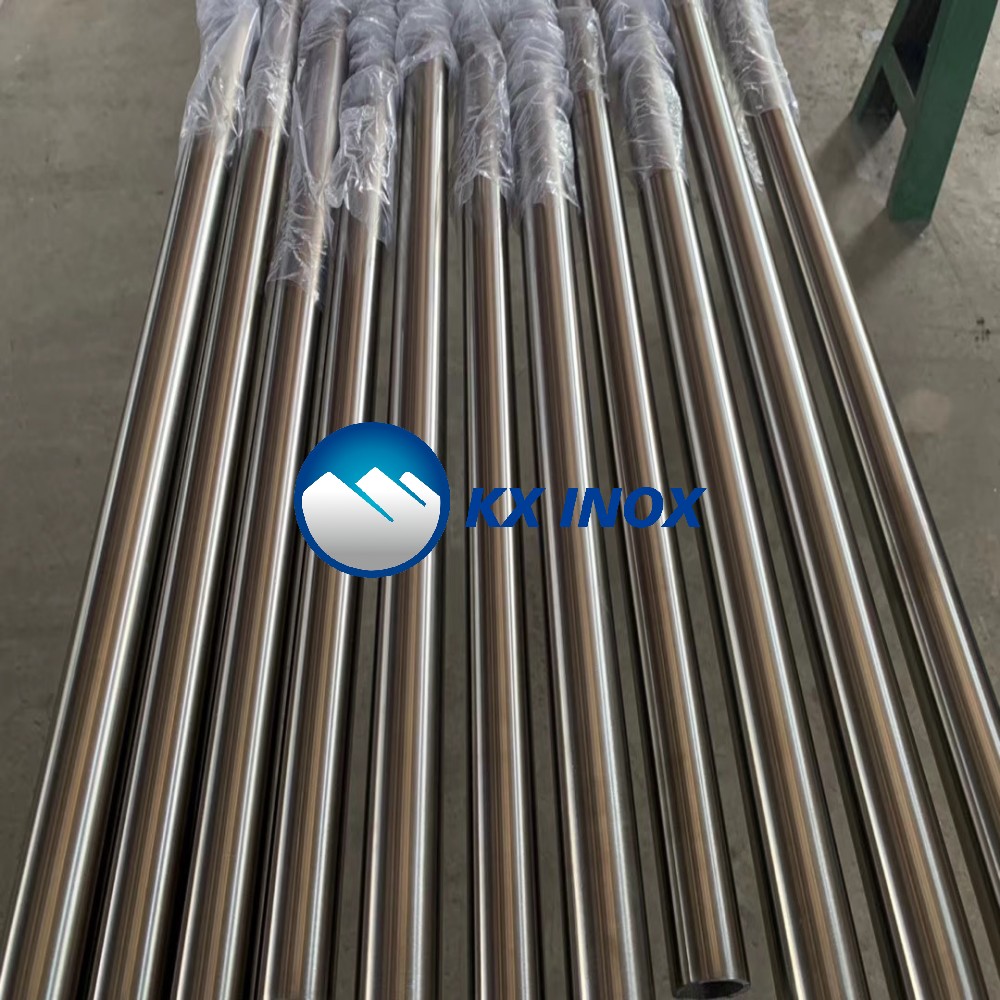

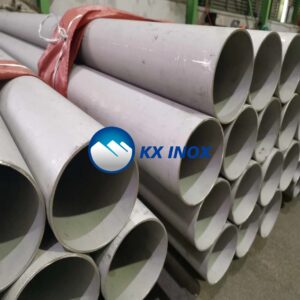

Sizing, Surface Finishes, and Customization Options

ASTM A269 TP304 stainless steel seamless tubes are available in an extensive range of sizes.

This versatility ensures that they can meet diverse application needs. Various diameters and lengths accommodate specific project specifications.

Customization options enhance their utility. You can select from different surface finishes. These include polished, brushed, and pickled finishes, which cater to aesthetic or functional requirements.

Options for customization include:

- Diameter and Length: Tailored to project needs.

- Surface Finish: Polirano, brushed, or pickled.

- Toplotni tretman: Adjusts mechanical properties.

These options make the tubes suitable for specialized industrial applications.

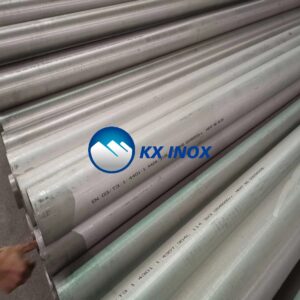

Quality Standards and Testing Procedures

ASTM A269 TP304 seamless tubes adhere to rigorous quality standards. Ensuring reliability and safety, these tubes meet both international and industry-specific requirements. Comprehensive testing guarantees their performance in demanding environments.

Key testing procedures for these tubes include:

- Hydrostatic Testing: Verifies pressure resistance.

- Non-destructive Testing: Detects internal flaws.

- Visual Inspection: Checks for surface defects.

These tests confirm the tubes’ integrity and consistency. Compliance with these standards ensures that the seamless tubes can safely serve various industrial applications.

Why Source ASTM A269 TP304 Seamless Tubes from China?

China is a leading supplier of ASTM A269 TP304 seamless tubes. Manufacturers in China offer high-quality products at competitive prices.

This makes them an attractive option for global buyers.

Key benefits of sourcing from China include:

- Cost Efficiency: Lower production costs lead to affordable prices.

- Quick Delivery: Efficient logistics ensure fast shipping.

- High Capacity: Large-scale production meets diverse demands.

Chinese suppliers consistently meet international standards, ensuring a reliable supply chain. Sourcing from China supports seamless integration into various industrial applications, enhancing project feasibility.

Conclusion

ASTM A269 TP304 stainless steel seamless tubes are essential in various industries. They offer durability, otpornost na koroziju, i termička efikasnost.

These qualities make them highly sought after for critical applications.

China’s leadership in producing these tubes ensures worldwide access to quality and cost-effective options.

By choosing Chinese suppliers, industries can benefit from expertise and production capabilities.

This ensures project success and optimal performance in demanding environments.

Wenzhou Kaixin Kaixin Metal Co., Ltd

Wenzhou Kaixin Kaixin Metal Co., Ltd